Digesters are of interest with regards to climate change, energy, air quality, and water quality. However, digesters are capital-intensive and difficult to maintain. Profitability of a farm-based digester usually requires utilizing the energy, carbon credits, tipping fees, and marketing other co-products such as manure solids that are separated out and composted.

The Environmental Protection Agency’s AgSTAR program has a website http://www.epa.gov/agstar/ with information to assist livestock producers who are considering installation of a digester. The website contains a database of farm digesters that are operating in the United States or that have operated in the past. It also provides a spreadsheet-based screening tool to help assess the potential feasibility of a project based on factors such as the feedstock, onsite conditions, the system type and size, and the planned biogas use.

What does a digester cost to install? Costs will vary widely depending on the situation, but the two sources discussed below show what some recent dairy farm digester installations have cost. The reports are the 2015 article by Manning and Hadrich, and the annual reports of the California Department of Food and Agriculture’s Dairy Digester Research and Development Program (CDFA).

The CDFA funded 117 dairy farm projects between 2015 and 2021. All but one of them were covered lagoon digesters (see the fact sheet by Hamilton for a discussion of digester types). Those funded in 2015 generated electricity, but most of those funded in 2017 and later have renewable natural gas (RNG) as the end-use of the biogas. The AgSTAR database lists the herd sizes for 19 of these digester projects that are producing RNG. For those projects, the average herd size was 7,479 cows and the average project cost was $947/cow or $4,384,479 total before deducting the CDFA grant. For the entire group of 117 projects, the CDFA grant funds covered 33 percent of the total cost.

The total cost of the greenhouse gas reductions achieved by these 117 projects was $30.94 per 1 metric ton of carbon dioxide equivalent including both the CDFA grants and the matching funds, or $9.88/1 metric ton considering only the CDFA grant funding. Those greenhouse gas reductions are calculated using methodology developed by the California Air Resources Board.

Manning and Hadrich report on 12 California dairy operations that had installed digesters and were using the biogas to generate electricity. They found that in 2014 the average initial cost of a lagoon system was $1.1 million ($869/cow with an average herd size of 2,496 cows) while a plug-flow system was $ 1.5 million ($1,114/cow and 1,620 cows). Subsidies covered around half of the initial investment on average.

The 12 Manning-Hadrich digesters included seven covered lagoon digesters and five plug-flow digesters. Seven of the digesters were providing benefits to the operations that exceeded their costs after subsidies. The other five were not operating profitably, including three of the plug-flows and two of the lagoon systems. Three of the unprofitable plug-flow digesters had ceased operation at the time of the study while the others were all operating. The seven profitable digesters had average annual operating costs of $0.98/cow while the five unprofitable ones averaged $2.72/cow.

Author: William F. Lazarus, University of Minnesota

Related:

Dairy Digester Research and Development Program (2022). Report of Funded Projects (2015-2022) 2022: Report to the Joint Legislative Budget Committee, California Department of Food and Agriculture, from https://www.cdfa.ca.gov/oefi/ddrdp/docs/2022_DDRDP_Legislative_Report.pdf.

Hamilton, D. (2019). “Types of Anaerobic Digesters.” Retrieved 8/4/22, 2022 from https://lpelc.org/types-of-anaerobic-digesters/.

Manning, D. T. and J. C. Hadrich (2015). “An evaluation of the social and private efficiency of adoption: Anaerobic digesters and greenhouse gas mitigation.” Journal of Environmental Management 154: 70-77.

U.S. AgSTAR. “AgSTAR: Biogas Recovery in the Agriculture Sector.” Retrieved 8/3/22, from http://www.epa.gov/agstar/.

-

Find these topics and many other related Farm Energy media resources at the Farm Energy Media archive.

Find these topics and many other related Farm Energy media resources at the Farm Energy Media archive.

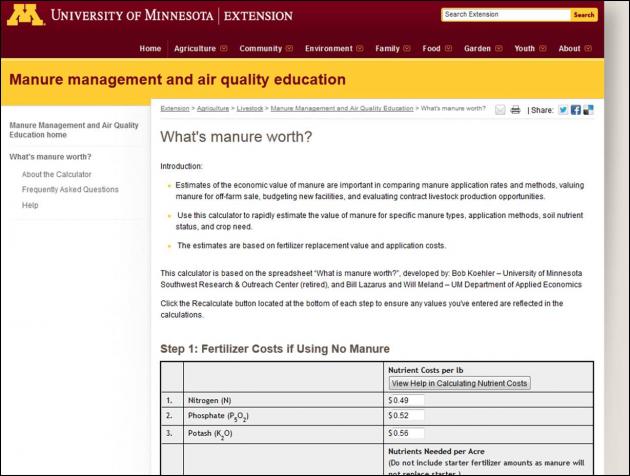

This situation motivates growers to optimize production methods, utilizing all resources including manure. In addition, an increase in the price of commercial fertilizer experienced since 2009, has heightened interest in the use of manure for supplying crop nutrients and has significantly increased the value of manure as a nutrient source.

This situation motivates growers to optimize production methods, utilizing all resources including manure. In addition, an increase in the price of commercial fertilizer experienced since 2009, has heightened interest in the use of manure for supplying crop nutrients and has significantly increased the value of manure as a nutrient source.