Purpose

MyFarms, the software development team that manages the Manure Management Planner (MMP) desktop application, is now making it easy for TSPs to make beautiful manure setback maps that comply with government guidelines for use in Comprehensive Nutrient Management Plans (CNMPs). After using the MyFarms web-based platform to navigate a simple process (described below), the TSP will be able to download three digital assets from MyFarms including: 1.) The *.mmp project file, 2.) The PDF manure setback map book, and 3.) Manure setback images. TSPs will benefit from producing these downloads whether they use MMP or not and at any point in the planning process (i.e., before, during, or after entering data into MMP).

What Did We Do?

TSPs will begin by using MyFarms, a cloud-based field data management platform, to automatically fetch field boundaries from other cloud-based applications, such as Climate FieldView or the John Deere Operations Center. If the producer does not use one of those systems, the TSP can upload shapefiles, after exporting them from a different system. Or, if the producer has no field boundaries available, they can be created in MyFarms using existing field geometries.

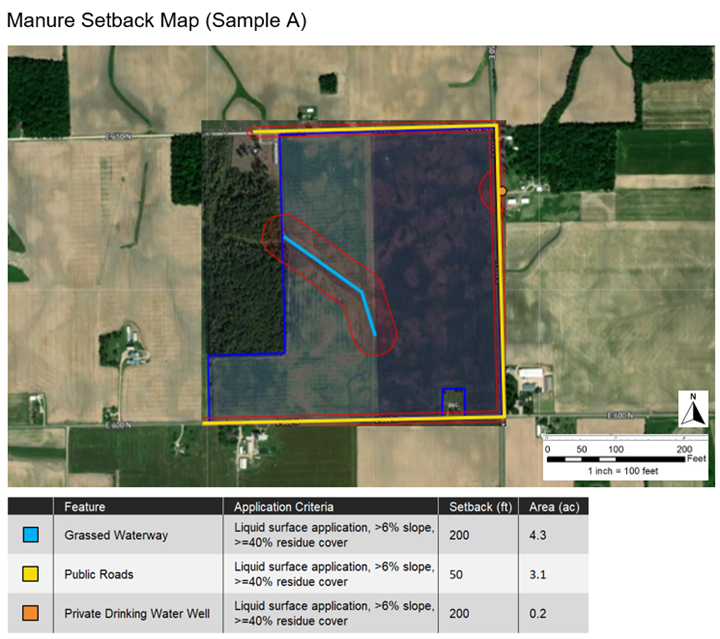

After setting up field boundaries, the TSP will navigate a wizard-like process to create a “Feature Map” including wells, streams, water control structures, facilities, and roads. Then, the TSP can create a “Manure Setback Map” (below), by specifying the manure application practice(s) associated with each feature. As each selection is made, MyFarms dynamically calculates the setback area surrounding the feature so the user can easily see the relationship between the application practice, the setback distance, and the setback area.

After a setback map has been created for each field, the TSP can export the data they entered in MyFarms as an *.mmp project file, which can be used to create a new project in MMP. If the TSP has already used MMP to generate a CNMP in Word format, they can export setback map images and paste them into the Word document. Or, if the TSP does not use MMP at all, they can export the setback maps as a standalone document in PDF format.

What Will You Learn in this Workshop?

You will learn of what NRCS is doing to modernize the manure management planning process through state-of-the-art, cloud-based software. As a starting point, you will learn how to create professional looking manure setback maps more accurately and easily than ever before. Following the workshop, MyFarms will be available to register your own account, so you can take what you have learned into your next CNMP-focused client engagement.

Future Plans

The MMP Download(s) solution is the first of numerous steps that will be taken by Purdue University, NRCS, and MyFarms to modernize the manure management planning workflow. Over time, state-specific policies, logic, and reference data will be added to this foundation, to deliver a more pleasing end-to-end user experience.

Authors

Chris Fennig, Managing Director, MyFarms

Corresponding author email address

chris.fennig@myfarms.com

Additional Information

purduemmp.myfarms.com

Acknowledgements

This solution is being built in partnership with Purdue University and NRCS.

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2022. Title of presentation. Waste to Worth. Oregon, OH. April 18-22, 2022. URL of this page. Accessed on: today’s date.