The recent development of the Newtrient on-line catalog (www.newtrient.com/Catalog/Technology-Catalog; see accompanying conference proceedings about the catalog) revealed the need to establish a set of environmental and farm operational based critical indicators (CIs). The indicators are useful in identifying manure treatment technologies that primarily best address dairy farm environmental sustainability but include some social aspects.

What did we do?

The Newtrient Technical Advancement Team, comprised of academic and industry professionals in dairy manure management, developed and implemented a novel methodology that identifies technologies that best address dairy farm sustainability mainly from an environmental but also from a social perspective. A project-amended process used by the International Organization for Standardization (ISO) was used as the basis for methodology development; the methodology is known as the Newtrient Evaluation and Assessment of Technology (NEAT) process.

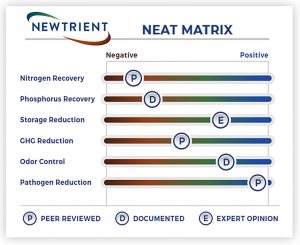

For this work, six specific CIs were selected based on key environmental challenges/opportunities facing the dairy industry; they are: nitrogen recovery, phosphorus recovery, liquid manure storage requirements, greenhouse gas reduction, odor reduction, and pathogen reduction. A literature search was performed to evaluate 20 manure treatment technology types under five technology categories (Table 1).

A scoring system relative to the baseline condition of long-term (anaerobic) manure storage was developed and applied to each technology type and an appropriate relative score for each CI was determined. The NEAT results are presented in an easy to understand dashboard called the NEAT Matrix (Figure 1).

What have we learned?

Use of the NEAT process across the 20 manure treatment technology types confirms that there is no single technology type that can address all the environmental and operational indicators. An integrated manure management system that is comprised of strategically selected technologies may be assembled to move each dairy farm toward sustainability.

| Table 1. Technology categories and associated manure treatment technology types evaluated using the Newtrient Evaluation and Assessment of Technology (NEAT). | |

|---|---|

| Technology Category | Evaluated Technology Types |

| Primary solid-liquid separation |

|

| Secondary solid-liquid separation |

|

| Physical and biochemical stabilization |

|

| Nutrient recovery |

|

| Energy recovery |

|

Future Plans

Future research in this area will continue to focus on using NEAT to evaluate integrated manure management systems designed specifically to achieve farm goals/needs.

Corresponding author, title, and affiliation

Curt Gooch, Environmental Systems Engineer, PRO-DAIRY Dairy Environmental System Program, Dept. of Animal Science, Cornell University.

cag26@cornell.edu

Other authors

Mark Stoermann (Newtrient, LLC), Garth Boyd (Context), Dana Kirk (Michigan State University), Craig Frear (Regenis), and Frank Mitloehner (UC Davis).

Additional information

Additional project information, is available on the Newtrient website: www.newtrient.com

Acknowledgements

Newtrient, LCC and the paper authors thank the following supporters of Newtrient: Agri-Mark, Inc., Dairy Farmers of America, Inc., Dairy Management Inc., Foremost Farms USA, Land O’Lakes, Inc., Maryland Virginia Milk Producers Cooperative Association, Inc., Michigan Milk Producers, National Milk Producers Federation, Prairie Farms Dairy, Inc., Select Milk Producers, Inc., Southeast Milk, Inc., St. Albans Cooperative Creamery, Tillamook County Creamery Association, and United Dairymen of Arizona

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2019. Title of presentation. Waste to Worth. Minneapolis, MN. April 22-26, 2019. URL of this page. Accessed on: today’s date.