There are known benefits and challenges to finishing beef cattle under roof. The accumulated manure is typically stored in either a bedded pack (mixture of bedding and manure) or in a deep pit below a slatted floor. Previous research measured particulate matter, ammonia and other gases in bedded pack barn systems. Deep pit manure storages are expected to have different aerial nutrient losses and manure value compared to solid manure storage and handling. Few studies have looked at concentrations at animal level or aerial/temperature distributions in the animal zone. There is little to no documentation of the air quality impacts of long-term deep pit manure storage in naturally ventilated finishing cattle barns. The objective of this work is to describe the seasonal and spatial variations in aerial ammonia concentrations in deep pit beef cattle barns.

What Did We Do?

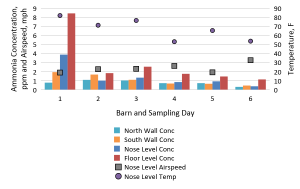

We measured ammonia concentrations among four pens in three beef cattle barns oriented east and west with deep pit manure storage during summer and fall conditions in Minnesota. We measured the concentration below the slatted floor (above the manure surface), 4-6 inches above the floor (floor level) and 4 ft above the floor (nose level). While collecting samples from within a pen, we also collected samples from the north and south wall openings surrounding the pen. We collected air and surface temperatures, air speed at cow level, and surface manure samples to supplement the concentration data. We collected measurements three times between 09:00 and 17:00 on sampling days. The cattle (if present) remained in the pen during measurement collection.

All farms had 12 ft deep pits below slatted floors, and pen stocking densities of 22 ft2 per head at capacity. Barn F finished beef cattle breeds under a monoslope roof, in four pens, with feed alleys on north and south side of pens. Two pens shared a common deep pit, and the farm pumped manure from the deep pits 1 week prior to the fall sampling period. Two pens were empty and the other two pens partially filled with cattle during the fall sampling period. Barn H finished dairy steers under a gable roof in a double-wide barn, in twelve pens over a deep pit and two pens with bedded packs, with a feed alley down the center of the barn. Four (east end) and eight (west end) pens shared common deep pits; the bedded pack pens were in the middle of the barn. The farm moved approximately 1 foot of manure from the east end pit to the west end pit one week prior to fall sampling period. Barn R finished dairy steers under a gable roof with four pens and a feed alley on the north side of the pens. All pens shared a common deep pit. Two pens were empty of cattle during the summer and fall sampling periods.

What Have We Learned?

The ammonia concentration levels differed based on the location in the pen area (Figures 1 and 2). As expected, the ammonia concentrations in the pit headspace above the manure surface was the greatest, and at times more than 10x the concentration at floor and nose level. The higher concentration levels measured at Barn F coincided with higher manure nitrogen levels (Total N and Ammonium-N) (Figure 2). Based on July and September measurements, higher ammonia concentration levels also coincided with higher ambient temperatures (Figure 1). The presence and size of cattle in the pens we measured did not strongly influence ammonia concentrations at any measurement height within a barn on sampling days.

Ammonia concentration is variable between barns, and within barns. However, at animal and worker level, average concentrations for the sampling periods were less than 10 ppm during the summer and fall periods. Higher gas levels can develop in the confined space below the slatted floor.

Future Plans

The air exchange between the deep pit headspace and room volume relates these two areas, but is challenging to measure. We are looking at indirect air exchange estimations using ammonia and other gas concentration measurements collected to quantify the amount of air movement through the slatted floor related to environmental conditions. Additional gas and environmental data collected will enhance our understanding of deep pit beef cattle barn environments.

Authors

Erin Cortus, Assistant Professor and Extension Engineer, University of Minnesota

Brian Hetchler, Research Technician, University of Minnesota; Mindy Spiehs, Research Scientist, USDA-ARS; Warren Rusche, Extension Associate, South Dakota State University

Additional Information

USDA is an equal opportunity provider and employer

Acknowledgements

The research was supported through USDA NIFA Award No. 2015-67020-23453. We appreciate the producers’ cooperation for on-farm data collection. Thank you to S. Niraula and C. Modderman for assisting with measurements.

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2019. Title of presentation. Waste to Worth. Minneapolis, MN. April 22-26, 2019. URL of this page. Accessed on: today’s date.