Purpose

The purpose of this study was to develop and analyze potential recipes for composting swine lagoon sludge. Composting is a simple treatment; it is widely adopted on farms, generates a stable value-added stackable product, and conserves organic matter and nutrients. All these benefits along with an affordable cost and lower environmental emissions make it a potential candidate for the management of lagoon sludge, a byproduct of swine operations in southeast US.

Sludge accumulation in lagoons can result in increased odor from lagoons, impact animal productivity, increase risk of environmental and social consequences and lead to operation non-compliance. Developing affordable sludge management alternatives is important because current practices (land application post dredging and dewatering using organic polymers and geo-bags) are not widely adoptable, cost-prohibitive and non-sustainable (Owusu-Twum and Sharara, 2020, Soil facts) and current farm nutrient management plans do not consider management of sludge nutrients.

What Did We Do?

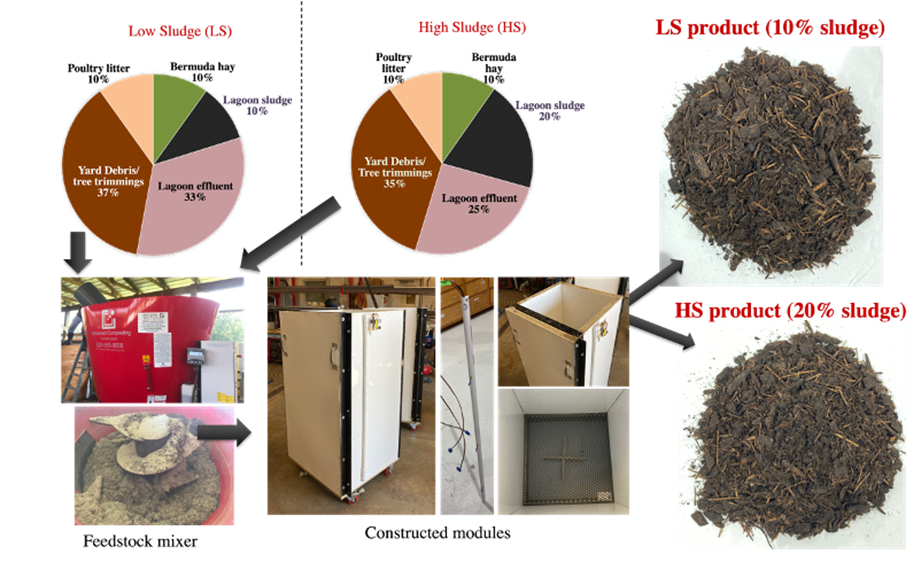

We developed two recipes by mixing different sludge amounts with locally available low-cost amendments: poultry litter, Bermuda hay, yard debris and lagoon liquid. We composted these recipes in triplicates using 13-cubic feet in-vessel composters and recorded changes in temperatures, weight loss, volume, moisture, and organic matter. We also recorded greenhouse gases emitted from the piles at regular intervals. Forced, intermittent aeration was maintained during composting for replicates to ensure adequate oxygen supply and avoid prematurely drying mixtures. Finally, we analyzed the final compost to determine its suitability as a soil amendment.

We used the observations from the experiments to evaluate if proposed recipes resulted in successful compost and determine whether sludge inclusion significantly impacts composting process and product quality. We also analyzed which factors influence weight and organic matter losses in the piles and if the proposed recipes have comparable cumulative GHG and NH3 emissions to previous observations.

What Have We Learned?

We learned that sludge can be composted at both 10% and 20% inclusion rates using the above ingredients, as the process met time and temperatures for pathogen reduction (15A NCAC, 13B.1406) and the final product were stable (TMECC, US Composting council). For 100 lbs. of an initial wet mixture (60.8 to 61.4% moisture) both recipes experienced a total weight loss of 33.8-35.2 lbs. with 24.5 to 25.4 lbs. being lost as moisture and 8.8 to 9.7 lbs. lost as organic matter during the active phase of composting (31 days). Post-screening the recipes resulted in 42.3 to 48.6 lbs. of the stable final product (45 to 47% moisture) that can be directly land applied.

We learned that the composting process generated similar GHG, and ammonia emissions as reported in the previous studies however, most of the methane (CH4) and nitrous oxide (N2O) were generated in the later stages of composting, which can be potentially reduced by proper management of the composting process. Another observation was larger losses in ammonia in the earlier stages of composting which on reduction; using certain additives, changes in recipe or management practices, can result in optimal utilization of nitrogen, increase product value, and reduce environmental impacts.

Future Plans

We plan to further analyze the impact of the composting process on total nutrients and water-extractable fractions, this will provide information on land use rate and potential losses in runoffs. This information is critical for swine lagoon sludge-derived products due to the high concentration of P, Zn, and Cu in sludge as losses can lead to eutrophication in surface and marine waters and potential toxicity in soils.

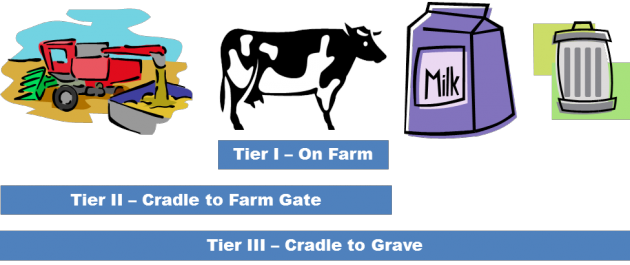

Future work proposed also involves techno-economic evaluation of this process to determine the cost of treatment, and fair price of the final product. We also plan to conduct a cradle to gate life cycle assessment of the process to determine global warming potential, eutrophication, acidification, and particulate matter generation for farm and large-scale systems. These efforts will help guide further research to improve the technology and provide knowledge to stakeholders and producers on alternative sludge management options.

References

-

- Owusu-Twum, M. Y., & Sharara, M. A. (2020). Sludge management in anaerobic swine lagoons: A review. Journal of Environmental Management, 271, 110949.

- Soil Facts, Karl A. Shaffer, Dianna Deanna L. Osmond, Sanjay B. Shah, Phosphorus Management for Land Application of Biosolids and Animal Waste, North Carolina Cooperative extension.

- Test Method for Examination of Composting and Compost (TMECC), US composting council, https://www.compostingcouncil.org/store/ViewProduct.aspx?id=13656204, last visited: Feb. 2022.

- 15A NCAC 13B .1406, Operational requirements for Solid waste Compost facilities, http://reports.oah.state.nc.us/ncac/title%2015a%20-%20environmental%20quality/chapter%2013%20-%20solid%20waste%20management/subchapter%20b/15a%20ncac%2013b%20.1406.pdf, last viewed: Feb 2022.

Authors

Piyush Patil, Ph.D. Candidate, Bio&Ag. Engineering, North Carolina State University

Corresponding author

Mahmoud Sharara, Asst. Professor and Extension Specialist, Bio&Ag. Eng. North Carolina State University

Corresponding author email address

Additional authors

Stephanie Kulesza, Assistant Professor, Crop & Soil Sciences, North Carolina State University

Sanjay Shah, Professor and Extension specialist, Bio&Ag. Eng. North Carolina State University

John Classen, Associate Professor, Bio&Ag. Eng. North Carolina State University

Additional Information

Publication is in progress currently so best resource is the corresponding author.

Acknowledgements

We would like to acknowledge the support from Joseph Stuckey and Chris Hopkins (Poultry, livestock, and animal waste management facility, NCSU).

Funding sources

Bioenergy Research Initiative (BRI) – Contract No #17-072-4015, North Carolina Department of Agriculture & Consumer Services

National Institute of Food and Agriculture (NIFA) – Critical Agricultural Research and Extension (CARE) – Award No. 2019-68008-29894, U.S. Department of Agriculture

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2022. Title of presentation. Waste to Worth. Oregon, OH. April 18-22, 2022. URL of this page. Accessed on: today’s date.

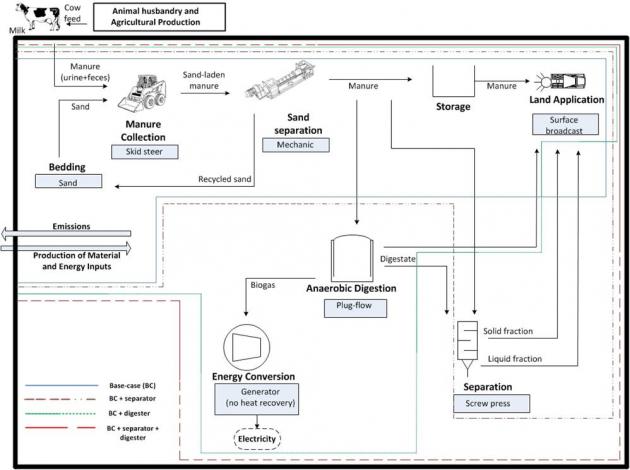

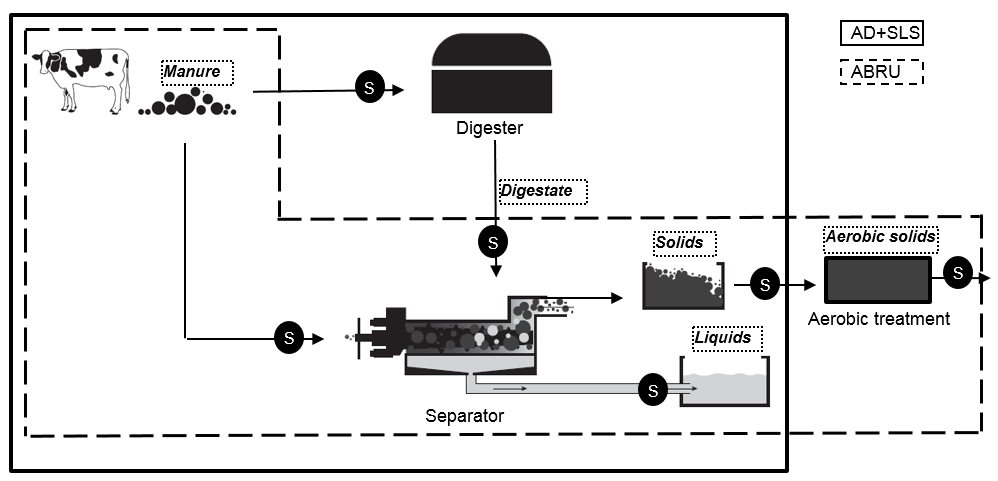

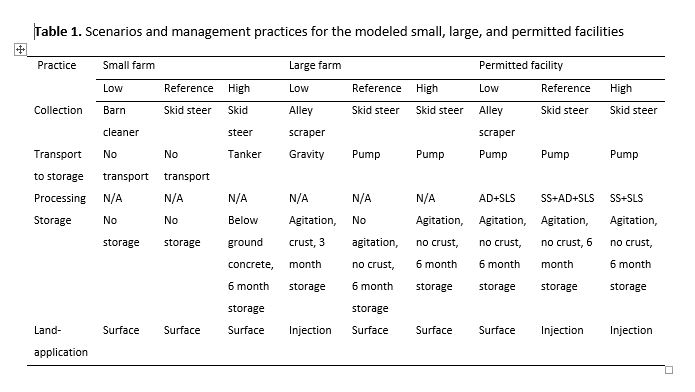

d collection, transportation, storage, land application, and processing (anaerobic digestion (AD), solid-liquid separation (SLS), and sand separation (SS)). Second, modelling tools were used to estimate GHG emissions based on farm size and practice. Four farm sizes have been evaluated: small (1-99 animal units, 1 AU = 1,000 pounds of animal), medium (100-199 AU), large (200-999 AU) and permitted facilities (≥ 1,000 AU).

d collection, transportation, storage, land application, and processing (anaerobic digestion (AD), solid-liquid separation (SLS), and sand separation (SS)). Second, modelling tools were used to estimate GHG emissions based on farm size and practice. Four farm sizes have been evaluated: small (1-99 animal units, 1 AU = 1,000 pounds of animal), medium (100-199 AU), large (200-999 AU) and permitted facilities (≥ 1,000 AU). storage. Emissions can be reduced by using a barn cleaner instead of a skid steer as it is more efficient in terms of energy consumption. The high emitting scenario in small farms indicates that adding long term storage would increase GHG emissions mostly in the form of methane (CH4) from storage.

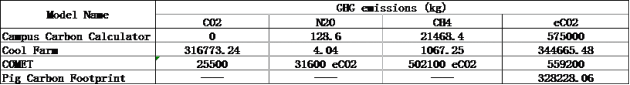

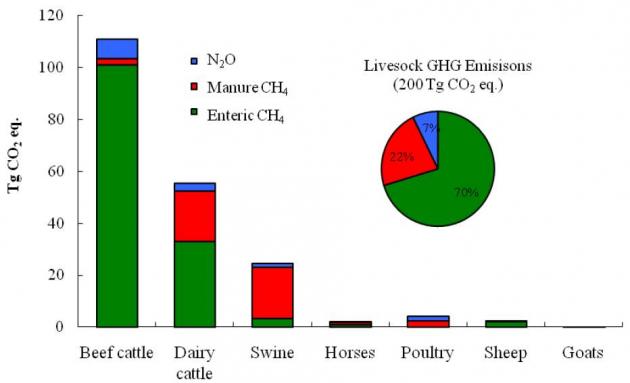

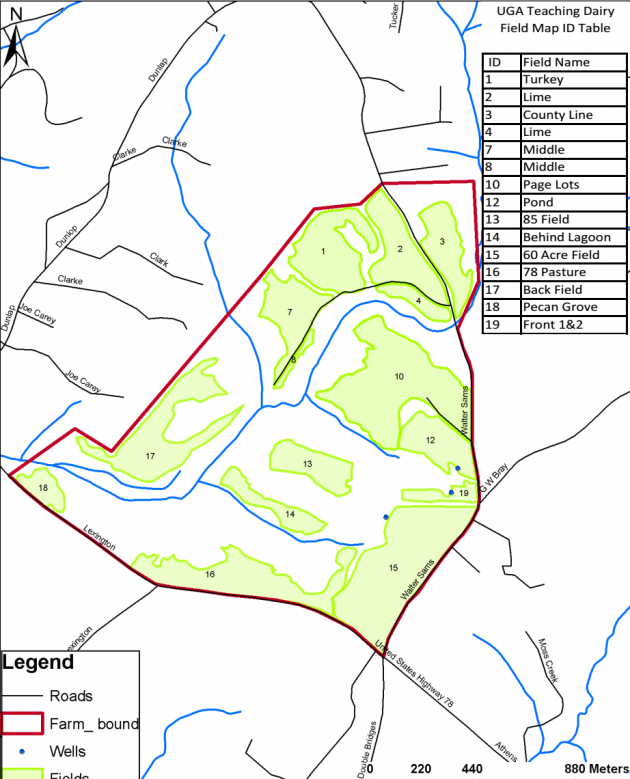

storage. Emissions can be reduced by using a barn cleaner instead of a skid steer as it is more efficient in terms of energy consumption. The high emitting scenario in small farms indicates that adding long term storage would increase GHG emissions mostly in the form of methane (CH4) from storage. Agriculture releases significant amounts of CO2, CH4 and N2O to the atmosphere. It is estimated that the agriculture sector contributes around 10-12% (~ 5-6 Gt CO2-equivelents yr-1 in 2005) of total global anthropogenic GHG emissions, which is about 50 and 60% of methane and nitrous oxide emissions, respectively. UGA made a commitment to reduce the GHG emissions. These emissions are currently calculated using a model called campus-carbon-calculator. However this model is limited in agricultural applications because it does not account for many management changes that might reduce GHG emissions. The purpos e of our project was to select or develop a model for estimating the GHG emissions from UGA farms. It was necessary for this model to account for crop production, dairy production and swine production and desirable for the model to have limited data requirements, be easy to use and allow for a variety of management options to reduce GHG emissions.

Agriculture releases significant amounts of CO2, CH4 and N2O to the atmosphere. It is estimated that the agriculture sector contributes around 10-12% (~ 5-6 Gt CO2-equivelents yr-1 in 2005) of total global anthropogenic GHG emissions, which is about 50 and 60% of methane and nitrous oxide emissions, respectively. UGA made a commitment to reduce the GHG emissions. These emissions are currently calculated using a model called campus-carbon-calculator. However this model is limited in agricultural applications because it does not account for many management changes that might reduce GHG emissions. The purpos e of our project was to select or develop a model for estimating the GHG emissions from UGA farms. It was necessary for this model to account for crop production, dairy production and swine production and desirable for the model to have limited data requirements, be easy to use and allow for a variety of management options to reduce GHG emissions. What have we learned?

What have we learned?