Purpose

The US Dairy industry established a voluntary environmental stewardship goal to achieve greenhouse gas (GHG) neutrality by 2050 among farmers and processors collectively. Manure management and enteric emissions combined account for approximately 70% of the GHG footprint of the US dairy industry, with nearly equal contributions from each (Thoma, 2013). There are multiple manure management systems used by dairy farmers in the Northeast and Upper Midwest that substantially impact GHG emissions. Quantification of GHG emissions for different manure management systems is necessary to compare options and strategies that can be applied to reduce GHG, especially methane, to move toward sustainability and reach the targets set by industry and governments.

Methane is the primary GHG emitted from the long-term storage of dairy manure, a water quality best management practice employed by many dairy farms today. Landfills are also a significant source of methane emission primarily due to degradation of organic waste, notably pre- and post-consumer food wastes (community substrates). Methane is a highly potent GHG that impacts warming by 25 – 28 times as much as carbon dioxide (CO2) on a 100-year global warming potential (GWP) time scale (US EPA). However, because methane has a lifespan in the atmosphere of around 12 years, it has been accounted for on a 20-year GWP scale (84 times the impact of CO2) by the State of New York (Climate Leadership and Community Protection Act). Manure management systems that substantially reduce methane, such as the co-digestion of manure with food waste, can achieve significant reductions of the GHG emissions associated with milk production.

What Did We Do?

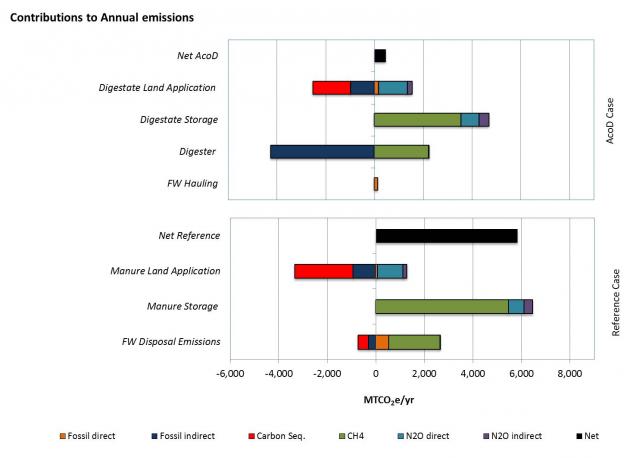

The GHG emissions resulting from the anaerobic co-digestion of raw dairy manure and community substrate (i.e., food processing waste mixture diverted from landfilling) in an equal mass of each (total mass basis) were calculated as part of a larger study comparing eight different manure management systems. The community substrate was modeled as 50% ice cream and 50% dog food by mass. Methane and nitrous oxide emissions were calculated with equations that use the mass flow of volatile solids (VS) and nitrogen through the co-digestion manure management system that included digestate solid-liquid separation using a screw press and the long-term storage of separated liquid. Carbon dioxide and methane associated with system energy use and energy production as pipeline-quality renewable natural gas (RNG), as well as landfill organics diversion were also calculated. The parasitic energy use (heat and electricity) of the digester and related manure management and biogas upgrading equipment was supplied on an average annual load basis by a portion of the biogas produced. The total net GHGs were summed using a CO2-equivalent (CO2e) methodology (both GWP100 and GWP20 were computed) and normalized on a per lactating cow per year basis. A sensitivity analysis of eleven variables was conducted to quantify the impact of each on the net GHG result.

What Have We Learned?

The co-digestion system net annual GHG impact was calculated to be −16 metric tons (MT) CO2e cow-1 (GWP100) and −43 MT CO2e cow-1 (GWP20). For the co-digestion mixture analyzed (50% liquid dairy manure, 25% ice cream, and 25% dog food), the anaerobic digester biogas production was 4 times greater than the biogas production for manure alone (on a per lactating cow basis). This significant energy production potential contributed an offset of 3.9 MT CO2 cow-1 year-1, assuming the net RNG after supplying the system’s parasitic energy usage displaced the CO2 emissions from combusting approximately 380 gallons of diesel. In comparison, a methane leakage (or loss) of 2% from the digester to RNG system was equivalent to 18% of the energy offset at GWP100 (0.7 MT CO2e cow-1 year-1) and 62% at GWP20 (2.4 MT CO2e cow-1 year-1). Despite the greater contribution of methane leakage at GWP20 on a CO2e basis, the methane offset from landfilling the community substrate also substantially increased, resulting in just a 5 – 6% increase in the net annual GHG (remaining net negative) when methane leakage was varied from 1 to 3% under both GWP time scales. The methane leakage amount was also the most sensitive variable studied for the co-digestion system and the relatively low impact on total net GHG indicates the effectiveness of this type of manure management system as a tool to reach net GHG neutrality.

Future Plans

A next step in the assessment of co-digestion of dairy manure and food waste diverted from landfills is to continue improvement of our Cornell Dairy Digester Simulation Tool that predicts biogas production from a variety of food wastes combined in different quantities with dairy manure. This tool will also allow for the economic feasibility analysis of different co-digestion system sizes and substrate mixtures, inclusive of tipping fee variation and energy generation options (electricity and RNG) and associated values. This work will help farmers assess the feasibility of implementing or participating in a co-digestion system for manure management.

In future work contingent on funding, we plan to conduct comprehensive field measurements of methane emissions from the long-term storage of raw manure, separated manure liquid, and digested effluent. The equations that calculate methane are gross and depend on volatile solid content and degradability of the stored material, as well as temperature and retention time. Verification of these equations and inputs will give more confidence in utilizing bottom-up calculations of GHGs from manure management practices.

Authors

Lauren Ray, Extension Support Specialist III, Cornell PRO-DAIRY Dairy Environmental Systems Program

Corresponding author email address

LER25@cornell.edu

Additional authors

Curt A. Gooch, Sustainable Dairy Product Owner, Land O’Lakes – Truterra; Peter E. Wright, Extension Associate, Cornell PRO-DAIRY Dairy Environmental Systems Program

Additional Information

More information on related work can be found on the Cornell University PRO-DAIRY website under Environmental Systems: https://cals.cornell.edu/pro-dairy/our-expertise/environmental-systems.

Thoma, G., J. Popp, D. Shonnard, D. Nutter, M. Matlock, R. Ulrich, W. Kellogg, D. S. Kim, Z. Neiderman, N. Kemper, F. Adom, and C. East. (2013). Regional analysis of greenhouse gas emissions from USA dairy farms: A cradle to farm-gate assessment of the American dairy industry circa 2008. Int. Dairy J. 31:S29–S40. https://doi.org/10.1016/j.idairyj.2012.09.010.

US EPA, https://www.epa.gov/ghgemissions/understanding-global-warming-potentials. Accessed 2/24/2022.

Climate Leadership and Community Protection Act. 2020. New York State Senate Bill S6599.

Acknowledgements

The Coalition for Renewable Natural Gas and the New York State Department of Agriculture and Markets provided a portion of the financial resources to support the development of this work.

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2022. Title of presentation. Waste to Worth. Oregon, OH. April 18-22, 2022. URL of this page. Accessed on: today’s date.