Purpose

Dairy manure was once considered a waste, but it can be transformed into a valuable resource. As demand for sustainable waste management grows, innovative ways for converting dairy manure are being actively researched to enhance both dairy productivity and environmental sustainability. One such method, hydrothermal carbonization (HTC), has recently garnered significant attention due to its ability to convert wet biomass into value-added products. HTC involves treating wet biomass, such as dairy manure with high water content, at moderate temperatures (180℃-250℃) and pressure. The outcome of HTC is hydrochar, a solid product with high carbon and nutrient content.

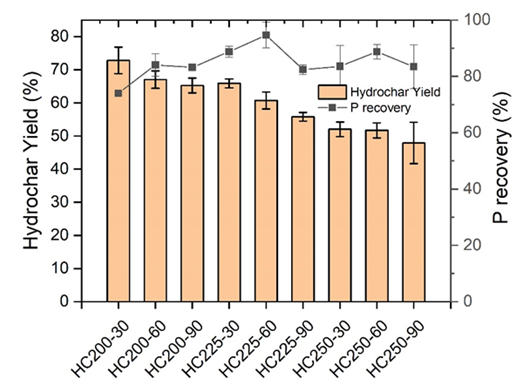

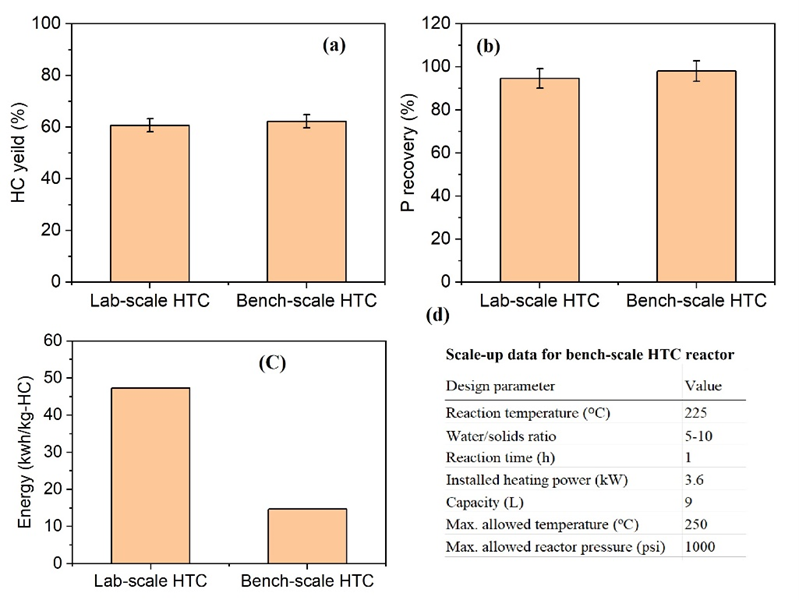

Hydrochar has strong potential as a means of soil amendment, carbon sequestration and/or biofuel. Our lab scale experiments showed that hydrochar retains more than 90% phosphorus (P) from dairy manure. For hydrochar production to become a viable technology for dairy farms, a continuous system is essential. Such a system would offer numerous benefits, including increased production, enhanced efficiency, and greater potential for commercialization. The purpose of this study is to design a pre-commercial conceptual process for the continuous production of hydrochar from dairy manure.

What Did We Do?

Manure management consists of collecting manure from the floor to utilize it in the best possible way. Most dairy farms treat manure through anaerobic digestion to produce energy, separate the solids for use as a bedding material, and/or apply directly to field applications. To explore alternative ways of handling the large quantities of manure in a quick chemical method and recycling nutrients back to the cropland, dairy manure is processed into P-rich hydrochar via an HTC process. Based on the results of our laboratory experiments, a conceptual process was developed, which is capable of treating dairy manure from a mid-size farm with 1,000 lactating cows and equates to 38,000 tons of manure per year with 8-10% solids. The process design includes engineering designing details of manure preparation and handling, feeding and discharge mechanisms, main equipment (such as HTC reactor and heat exchangers), heating and temperature controls, and schemes for post-HTC process wastewater (post-water) handling. Figure 1 is the schematic of the conceptual process with major process equipment, where the thick, black lines indicate the flow of dairy manure slurry containing solids, while the thin, blue lines represent the flow of post-processed water.

Firstly, dairy manure collected from the dairy barns (approx. 10% solids) is stored in a storage tank (T-101) before being pumped into the feeding tank (T-102), where it is heated to 167°F (75°C) by the recycled post-water from preheater I (E-201) through internal heating coils. The feeding tank is equipped with a marine-style impeller for agitation to maintain solid suspension. Two preheaters (E-201 and E-202) are used to further heat the slurry to the required HTC temperature before entering the reactor (R-301). Preheater I is a shell-and-tube heat exchanger to heat the slurry up to 320°F (160°C) by heat recovery using the hot post-water from post-water tank (T-304). Preheater II is a tubular electric heater and is to finish the last stage of heating to 437°F (225°C). A continuously stirred tank reactor (CSTR) with agitation is the main equipment to thermochemically process dairy manure into hydrochar. After a 30-minute retention time in the reactor, the resulting product mixture is collected in the receiving tank/separator (T-302). Then the hot post processed-water is separated from the solid (the wet hydrochar cake) and collected in a storage tank (T-304) before being used as a heating medium for heat recovery. The wet hydrochar cake coming out of decanter centrifuge (T-303) is dewatered through an air-drying unit (C-305) to a water content of 12% or less, which can be used directly for land applications or packaged and transported to other markets.

What Have We Learned?

Continuous hydrochar production holds great potential for recycling phosphorus from dairy manure back into the cropland as a soil amendment and for sequestrating carbon back to the soil. The conceptual process represents a significant step towards practically promoting this alternative manure treatment technology and creating a value-added product for nutrient cycling. This process is capable of producing approximately 5 million pounds (2,300 metric tons) of air-dried hydrochar per year, a yield of about 60% of the solid matter from dairy manure, and with a phosphorus concentration of approx. 1.4 lb/100 lb. Hydrochar is hydrophobic and can be sufficiently dried by ambient air. The air dried hydrochar contains a moisture content of 12% or less (as low as 5% per laboratory results due to hydrochar’s hydrophobic characteristics) and is suitable for long term storage and/or distance transportation. Because the raw, wet dairy manure can be processed directly from the farm without any pretreatment, the HTC process offers a good possibility for a cost-effective waste management alternative while producing valuable hydrochar for phosphorus recycling.

Future Plans

Upon completing this continuous flow process design, we will conduct a techno-economic assessment (TEA) to provide insights into the system’s economic feasibility, cost structure, and profitability. The TEA study will also offer a better perspective on the economic viability, technical challenges, and potential profitability of adopting and investing in the continuous hydrochar production system from dairy manure for waste management and nutrient cycling.

Authors

Presenting author

Imran Hussain Mahdy, Graduate Student (Ph.D.), University of Idaho

Corresponding author

Brian He, Professor, University of Idaho, bhe@uidaho.edu

Acknowledgements

USDA AFRI, UADA NIFA and Idaho Agricultural Experiment Station are acknowledged for their financial support through Sustainable Agricultural Systems (SAS) program (Grant 2020-69012-31871), and hatch project of IDA0-1716 (Accession number1012741).

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2025. Title of presentation. Waste to Worth. Boise, ID. April 7–11, 2025. URL of this page. Accessed on: today’s date.