Proceedings Home | W2W Home

Purpose

Animal manure contains nutrients and organic matter that is valuable to crop producers if it can be efficiently applied to nearby fields, however this can be a significant source of environmental contamination if managed incorrectly. In most cases, concentrated animal production facilities are rarely close to sufficient cropland to fully utilize these resources and management becomes a disposal issue rather than a utilization opportunity. The goal of this work is to design and test a pilot-scale system to implement a hydrophobic, gas permeable, expanded polytetraflouroethylene (ePTFE) membrane (U.S. patent held by USDA) to recover ammonia from swine wastewater in a solution of sulfuric acid. The pilot-scale system results are described elsewhere; the purpose of this presentation is to explore the best applications for this and other recovery technologies in animal feeding operations.

What did we do?

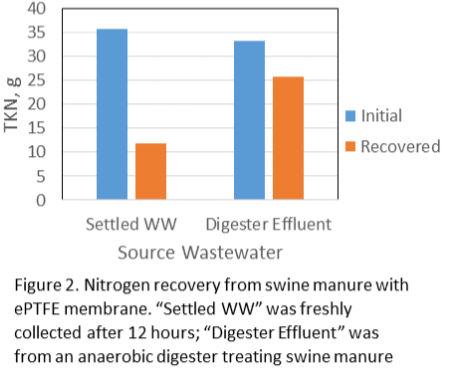

The reactor test (figure 1) system consisted of 19 membrane tubes (ID of 0.16 in, wall thickness of 0.023 in) within a 2.01 in diameter, 24.7 in long reactor giving a membrane density of 3.83 in2 in-3 of reactor. Wastewater first passed through a CO2 stripping column (4.016 in diameter, 55 in length) where a small air stream (0.0614 ft 3 min-1) stripped CO2 from the wastewater and raised the pH one full unit, shifting the equilibrium to NH3 and enhancing transport across the membrane. Batch tests (0.706 ft3) were run for 9-12 days with wastewater recirculating at a rate of 0.16 gal min-1. The recovery fluid inside the tubular membranes was a 0.01 N sulfuric acid solution with the pH automatically maintained below 4.0 standard units and recirculating at a rate of 1/100th the wastewater flowrate. Freshly collected settled wastewater and anaerobic digester effluent were tested to determine the mass of ammonia collected, the acid required to main! tain the low pH of the recovery solution and potential ammonia losses to the atmosphere.

What have we learned?

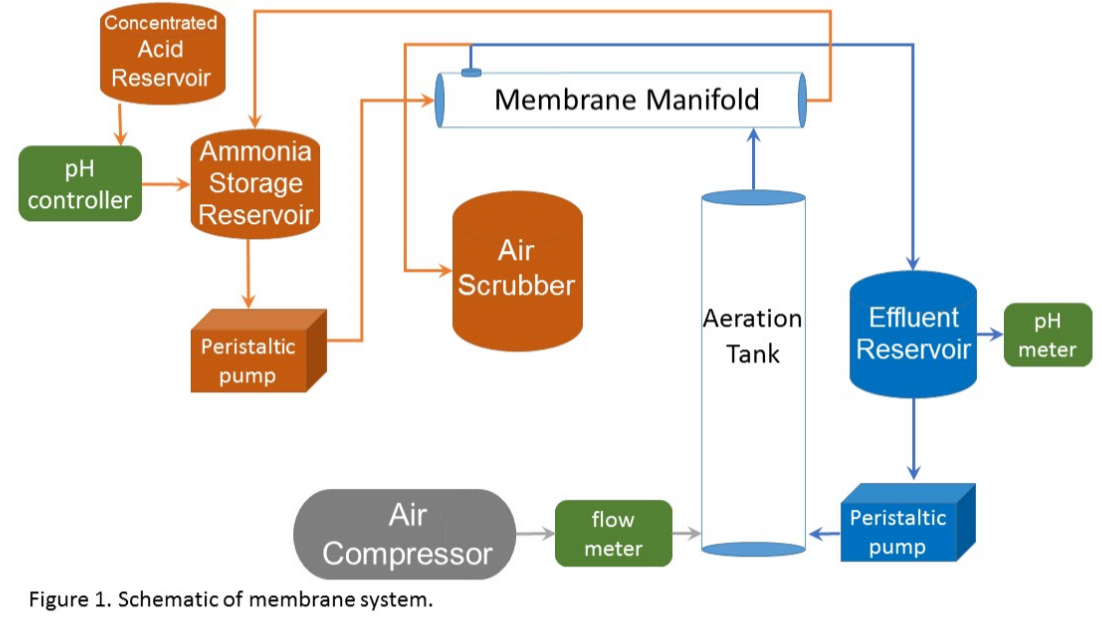

The batch volumes of the two sources contained about the same mass of nitrogen (35.6 g in freshly collected settled wastewater and 33.2 g in digester effluent) but the higher fraction of ammonia in digester effluent resulted in greater recovery (77% vs. 33%).

Future Plans

The best use of this and other recovery technologies cannot be determined by simply comparing the cost of installation and operation with the price of the recovered product. The question of where and how to implement such recovery technologies requires knowledge of the value added by each process and further needs an understanding of how various practices interact and contribute to a sustainable system. Process interactions will suggest one step come before another because of the characteristics produced by one and needed by the other. Anaerobic digestion effluent has different characteristics than the output of a hydrothermal process. As seen in the membrane results, freshly collected liquid waste has a different ammonia : organic nitrogen ratio than digester effluent. Source separated manure solids have high levels of organic phosphorus but digester effluent has high concentrations of dissolved phosphate.

Product recovery is only the beginning of the valuation process; as an industry and as a society, we value conservation for other reasons. We do not yet have a well-accepted way to quantify that value. The avoided cost of nitrogen removal from surface waters is a good start to estimate the value of keeping nitrogen out of drainage and runoff but what is the quantified value of preserving the ecosystem services that excess nitrogen disrupts? The cost of recovered phosphorus may be high relative the current price of virgin phosphate from ore but the value of that recovery process includes the avoided problems in rivers, lakes, and estuaries caused by excess nutrients. The fertilizer value of recovered ammonia that was prevented from escaping to the atmosphere may be small compared to the avoided cost of particulate pollution and the associated health problems.

In addition to improved operation of the membrane reactor system, at least three things are needed to fully realize the value of resource recovery:

1. Cost-effective dewater processes. Rejecting inert water can reduce the capital and/or operating cost of almost all waste management processes;

2. Process to quantify the value of ecosystem services and avoided costs of recovery;

3. Cooperation of and investment from major stakeholders in the form of research funding as well as collaboration regarding processes and feed stocks for fertilizer and feed formulations. Animal production companies have historically been involved but fertilizer companies, feed mill operators, animal nutritionists and others must also be involved.

Corresponding author, title, and affiliation

John J. Classen, Associate professor, Biological and Agricultural Engineering, NC State University

Corresponding author email

Other authors

J. Mark Rice, Extension Specialist, Biological and Agricultural Engineering, NC State University, Kelly Zering, Professor and Extension Specialist, Agricultural and Resource Economics, NC State University

Additional information

John J. Classen

Biological and Agricultural Engineering

Campus Box 7625

North Carolina State University

919-515-6755

Acknowledgements

This project was supported by NRCS CIG Award 69-3A75-12-183. The authors are grateful for the analytical work of the BAE Environmental Analysis Laboratory, Dr. Cong Tu, manager.

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2017. Title of presentation. Waste to Worth: Spreading Science and Solutions. Cary, NC. April 18-21, 2017. URL of this page. Accessed on: today’s date.