![]() Waste to Worth home | More proceedings….

Waste to Worth home | More proceedings….

Why Study Air Emissions from Mono-slope Beef Barns?

Mono-slope buildings (Figure 1) are one type of roofed and confined cattle feeding facility that is becoming increasingly popular in the Northern Great Plains. However, little is known about the impact of these housing systems and associated manure management methods on the air quality inside and outside the barn. The objective of this study was to determine gas concentrations in mono-slope beef cattle facilities and relate these concentrations to environmental and manure management factors.

|

| Figure 1. View of a monoslope cattle facility from the northeast. Adjustable curtains in the rear (north) wall are used to limit airspeed through the barn during colder weather. |

What Did We Do?

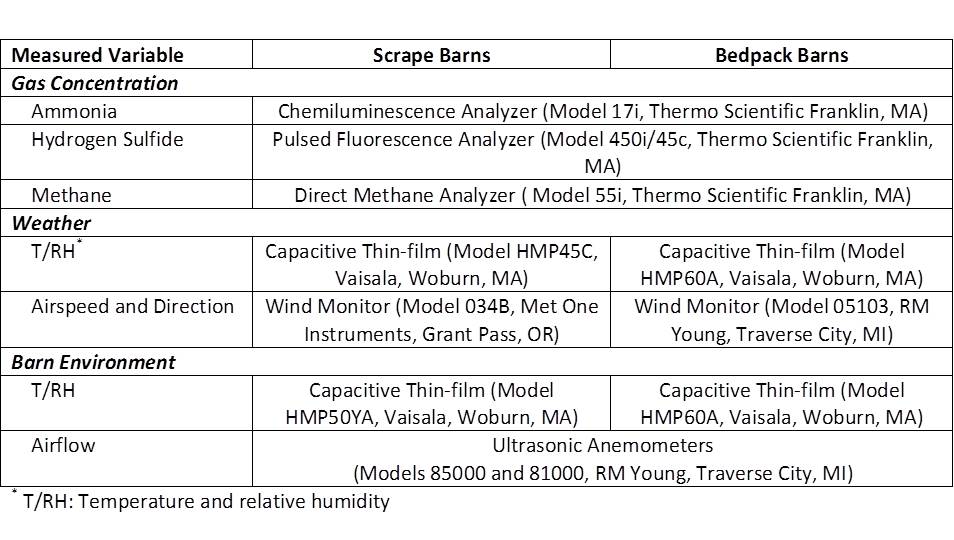

Four producer-owned and operated beef deep-bedded mono-slope facilities were selected for monitoring. Two barns maintained deep-bedded manure packs (Bedpack), whereas two barns scraped manure and bedding from the pens weekly (Scrape). Each site was monitored continuously for one month each quarter for two years to capture both daily and seasonal variations. At each facility, the environment-controlled instrument trailer and associated equipment were located adjacent to the barn. The trailer contained: a gas sampling system (GSS) that consisted of Teflon tube sample lines connected to a computer-controlled sampling manifold, gas analyzers, computer, data acquisition system, calibration gas cylinders, and other supplies. In addition to the sampling lines, there were environmental instruments to measure the airflow and weather conditions for two pens in each barn. The analyzers and sensors used are summarized in Table 1.

|

|

|

Ammonia, hydrogen sulfide and methane concentrations were sequentially sampled from two south wall locations and three north wall locations per pen. The maximum hourly mean concentrations measured at the north or south wall of either pen in the barn were used in this analysis. The seasonal average hourly means of maximum concentrations and corresponding environmental variables were calculated.

What Have We Learned?

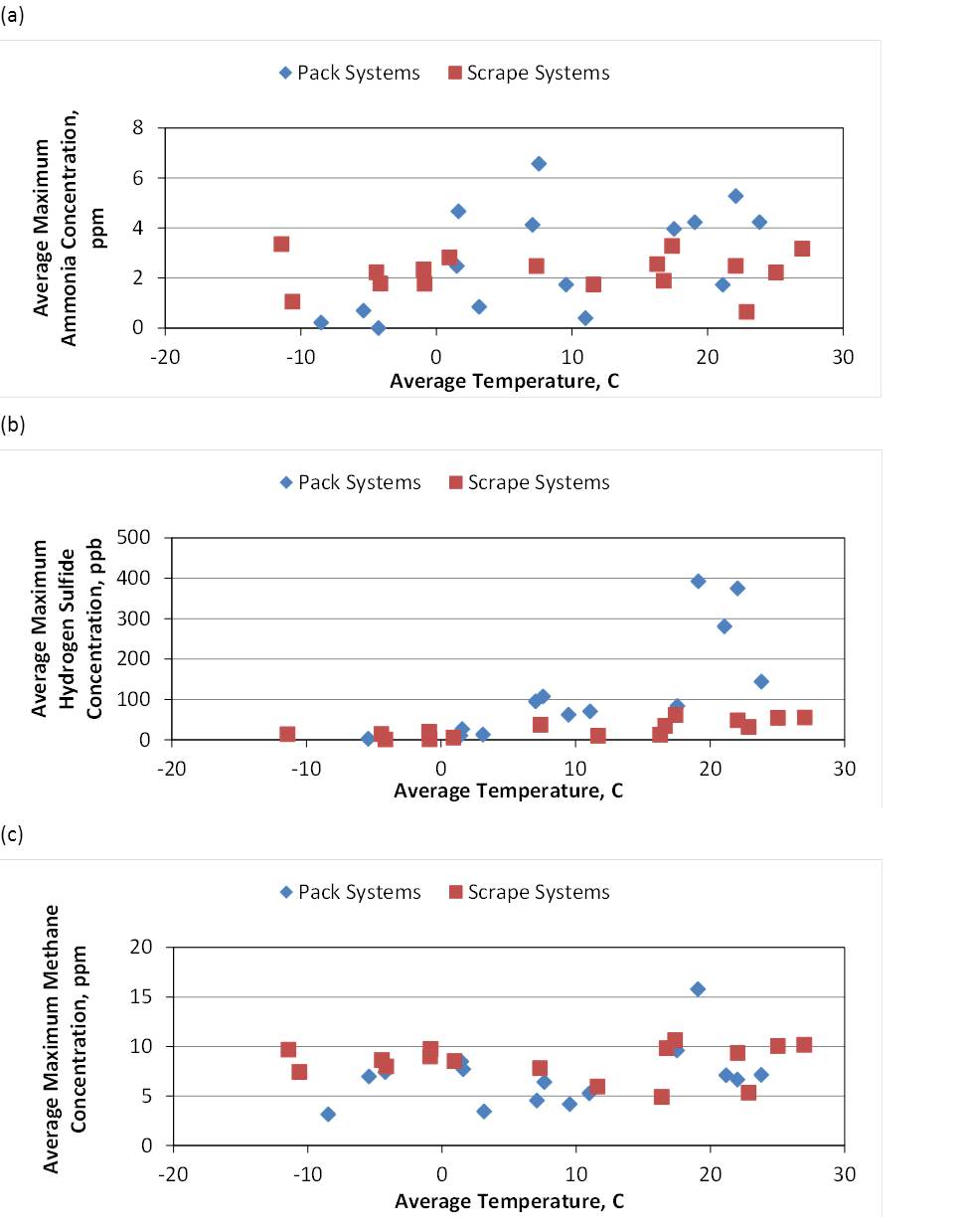

The seasonal average hourly maximum ammonia concentration ranged from 0.6 to 3.3 ppm with the Scrape barns and from 0.2 to 7.1 ppm with the Bedpack barns (Fig 2a). The range of maximum hydrogen sulfide concentrations was 0 to 61 ppb in the Scrape barns and 0 to 392 ppb in the Bedpack barns (Fig 2b). The maximum methane concentration ranges were 4.9 to 10.6 and 3.1 to 15.8 ppm in the Scrape and Bedpack barns, respectively (Fig 2c). There are indications of differences between gas release rates for bedpack and scrape manure management systems and increased release rates with temperature for ammonia and hydrogen sulfide. Methane concentrations were more consistent between systems and for different temperature conditions.

This project expands the knowledge base of gaseous concentrations from deep-bedded beef barns. This integrated project also provides management techniques that producers can implement to minimize emissions, and improve air quality.

Future Plans

Emission values will be calculated using these concentration data, in conjunction with airflow data, which also varies with site and temperature conditions.

Authors

Erin L. Cortus, Assistant Professor, South Dakota State University, erin.cortus@sdstate.edu

Md Rajibul Al Mamun, Graduate Research Assistant, South Dakota State University

Ferouz Y. Ayadi, Graduate Research Assistant, South Dakota State University

Mindy J. Spiehs, Research Animal Scientist, USDA ARS Meat Animal Research Center

Stephen Pohl, Professor, South Dakota State University

Beth E. Doran, Extension Beef Program Specialist, Iowa State University Extension and Outreach

Kris Kohl, Extension Ag Engineer Program Specialist, Iowa State University Extension and Outreach

Scott Cortus, Engineering Research Technician, South Dakota State University

Richard Nicolai, Associate Professor (Retired), South Dakota State University

Additional Information

- Mono-slope air quality research project website

- Design and management of mono-slope barns (archived webcast)

- Introduction to mono-slope cattle facilities

Acknowledgements

Project funded by Agriculture and Food Research Initiative Competitive Grant no. 2010-85112-20510 from the USDA National Institute of Food and Agriculture. Technical assistance provided by Alan Kruger, John Holman, Todd Boman, and Bryan Woodbury.

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2013. Title of presentation. Waste to Worth: Spreading Science and Solutions. Denver, CO. April 1-5, 2013. URL of this page. Accessed on: today’s date.