Spring in the upper Midwest can be short, resulting in challenges for producers to apply manure and plant crops in a timely manner to maximize yield. This results in a significant amount of manure applied in the fall after the crop is harvested. Fall applied manure has ample time to mineralize and leave the root zone before next season’s crop can utilize the nutrients. These nutrients can end up in rivers and other freshwater bodies decreasing water quality. Sidedressing manure in growing crops could provide producers with another window of opportunity to apply their manure, maximize nutrient uptake efficiency, and protect water quality. The summer of 2018 was the start of a two-year, on-farm study researching the effectiveness of sidedressing slurry swine manure to corn via dragline hose. The swine manure was compared to sidedressed anhydrous ammonia, 32% urea ammonium nitrate (UAN), and a control that received no additional nitrogen at the time of sidedressing.

What we did

Corn was planted May 7th with a 12-row planter equipped to apply an in-furrow and top dressed liquid fertilizer. The total fertilizer applied at planting was 40.7 lbs of nitrogen (N), 19.8 lbs of P2O5 phosphorus (P), and 14.4 lbs of sulfur (S) per acre.

Sidedressing the nitrogen sources

We sidedressed all treatments on June 4-5 with 140 pounds of available N, except the control which had no additional N applied. All the equipment applied nutrients between 30-inch rows and fit a 12-row planter to match up on odd rows.

- Anhydrous ammonia treatment = 12-row toolbar and tractor were supplied by the farmer.

- Finishing hog manure dragline hose treatment = The toolbar for the dragline hose sidedress was supplied by Bazooka Farmstar. The toolbar is a coulter till 28-foot bar with 30-inch spacing.

- UAN treatment = The tool bar for the UAN sidedress application was provided by a local farmer.

- Control treatment = The control treatment did not receive any fertilizer at sidedress.

Soil data collection methods

Soil nitrate and ammonium samples were taken 5 times through the growing season, approximately every 4 weeks, to track nitrogen in the soil profile. Soil sample depths were 0-6, 6-12, and 12-24 inches from the soil surface. Soil

samples were taken from the middle of the interrow, 7.5 inches from both sides of the middle of the inter row and in the middle of the row. This sample method assured soil samples would be representative of the soil profile since banded fertilizer can skew results.

Yield data collection methods

Yield was harvested October 6th by a combine with a 6-row head. The combine took the middle 12 rows of the 24-row treatment reducing the side effects from neighboring treatments. A calibrated weigh wagon measured the weight of each combine pass which was calculated to find yield in bushels per acre for every sample.

What we have learned

First year data revealed all sidedressed nitrogen sources significantly increased corn yields over the control but were otherwise statistically similar (Figure 1).

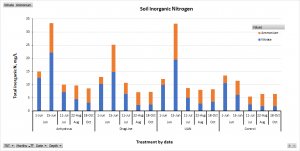

When we analyzed the soil inorganic nitrogen by each date differently, nitrogen concentrations between treatments were only statistically different on the soil sample date of June 15th (Figure 2) This soil sample date was ten days after the sidedress application on June 4th. All other soil nitrogen sample dates are not statistically different between treatments and even the control.

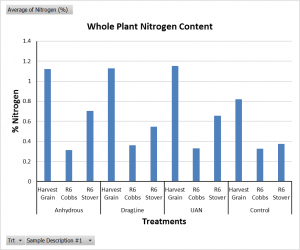

Statistics have not yet been run on the whole plant nitrogen content data in the graph below but numerically there doesn’t seem to be a difference in nitrogen content between the three sidedress treatments but a difference from the control (Figure 3).

Future plans

The first year of data was collected during the 2018 growing season and a second year of data will be collected in the summer of 2019. This study aims to evaluate the effectiveness of sidedressed swine manure slurry compared to traditionally used synthetic fertilizers. Since we have seen promising results this first year an additional study that could follow this experiment would be a direct comparison of fall applied swine manure and sidedressed swine manure. This information would help us understand the efficiency of sidedressing compared to fall application. Soil samples from this study would also illustrate the difference in mineralization and nitrogen movement between fall-applied and sidedressed swine manure slurry.

Authors

- Chris Pfarr, M.S. student in the Land and Atmospheric Sciences Program, University of Minnesota, pfarr025@umn.edu

- Melissa Wilson, Ph.D., Assistant Professor and Extension Specialist, Department of Soil, Water, and Climate, University of Minnesota, mlw@umn.edu

Additional information

- YouTube video of sidedressing manure: https://www.youtube.com/watch?v=DHaqmyS1zuU&t=12s

- Follow Dr. Wilson on Twitter: @manureprof

- Sidedressing manure in Ohio: https://lpelc.org/replacing-commercial-sidedress-nitrogen-with-liquid-livestock-manure-on-emerged-corn/

Acknowledgements

This project was partially funded by the Minnesota Soybean Research and Promotion Council and the Minnesota Pork Board.

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2019. Title of presentation. Waste to Worth. Minneapolis, MN. April 22-26, 2019. URL of this page. Accessed on: today’s date.