This study has the objectives of characterizing dairy manure pre and post solid-liquid separation (SLS), estimating and comparing processing efficiencies between different technologies, and relating emissions to manure characteristics by using modeling tools.

What did we do?

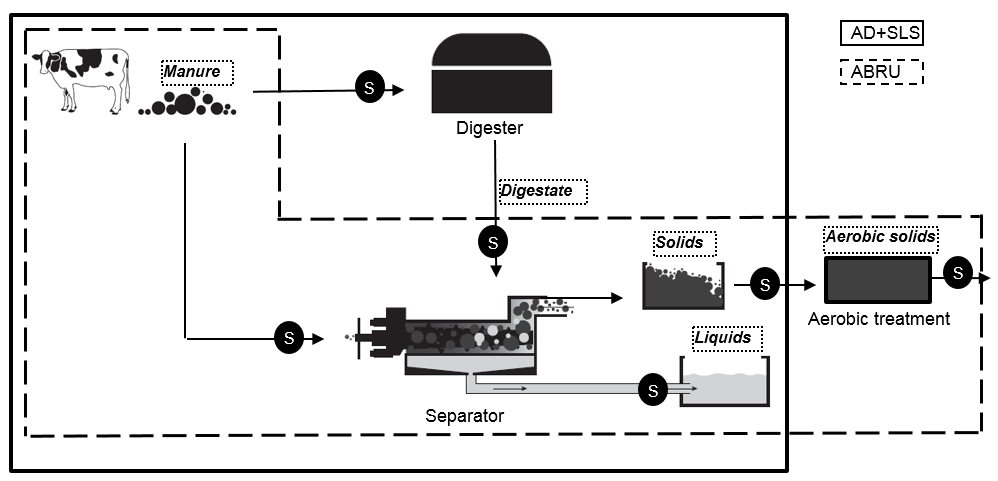

Manure samples from nine dairy farms in southern and eastern Wisconsin were collected every two weeks. All nine farms separated manure into liquid and solid streams and seven farms used anaerobic digesters (ADs) prior to solids separation (Table 1). For all farms, manure was sampled pre-processing (untreated manure) and after any individual processing step in order to isolate the performance of each treatment unit at each farm (Figure 1). All manure samples were analyzed for total solids (TS), volatile solids (VS), total nitrogen (TN), ammonia (NH3), total phosphorus (TP), total potassium (TK) and chemical oxygen demand (COD). Separation efficiency was estimated by solving a system of two equations of separation mass balance (Equations 1 and 2) based on the concentrations of each constituent.

Where:

-

-

-

- X (kg) is the constituent under evaluation (e.g. TS, NH3, etc.)

- [ ] indicates percent concentration in the solid (solid, out), liquid (liquid, out) fractions after separation, and total before separation (total, in)

- Manure (kg) is the manure mass in the solid (solid, out), liquid (liquid, out) fractions after separation, and total before separation (total, in)

-

-

What have we learned?

Both screw press and centrifuge technologies achieve higher separation efficiencies for TS and VS than for TN, NH3, TP, and TK, meaning that more TS and VS stay with the solids fraction. Moreover, NH3 stays almost entirely in the liquid fraction. Results indicate that centrifugation might achieve higher TP separation efficiencies than screw pressing. Greenhouse gas (GHG) emissions, were affected by the management practices used to handle the liquid and solid fractions. Methane emissions from liquid storage are reduced as a percentage of the VS stays with the solids fraction. However, nitrous oxide emissions from the separated solids might increase if separated solids are stored and not quickly land applied or transported outside of the farm for posterior use.

Future Plans

Analysis for anaerobic digestion efficiency and pathogen inactivation will be incorporated in this study to conduct a complete assessment of manure characteristics after AD and SLS and their impact on different environmental indicators.

| Table 1. Summary of each farm’s manure management process. | |||

|---|---|---|---|

| Farm ID |

AD |

SLS |

Feedstock |

| 1 |

Mixed plug flow |

Screw press |

Dairy manure |

| 2 |

No |

ABRU |

Dairy manure |

| 3 | Complete Mix |

Screw press with blower |

Dairy manure |

| 4 |

Mixed plug flow |

Screw press |

Dairy manure |

| 5 |

Mixed plug flow |

Screw press |

Paunch manure, food waste |

| 6 |

Mixed plug flow |

Screw press |

Dairy manure |

| 7 |

Mixed plug flow |

Screw press |

Dairy manure |

| 8 |

Complete Mix |

Centrifuge |

Dairy manure, ethanol byproduct, FOG |

| 9 |

No |

ABRU |

Dairy manure |

| AD: anaerobic digestion, SLS: solid-liquid separation, ABRU: aerobic bedding recovery unit , FOG: fat, oil, and grease | |||

Authors

Aguirre-Villegas Horacio Andres. Assistant Scientist. Department of Biological Systems Engineering, University of Wisconsin-Madison. aguirreville@wisc.edu

Sharara Mahmoud. Assistant Professor. Department of Biological and Agricultural Engineering. NC State University

Larson Rebecca. Associate Professor. Department of Biological Systems Engineering, University of Wisconsin-Madison

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2019. Title of presentation. Waste to Worth. Minneapolis, MN. April 22-26, 2019. URL of this page. Accessed on: today’s date.