Purpose

Improvements in manure treatment/nutrient management are an important need for dairy farms to move substantively towards sustainability. This project quantifies several individual manure treatment components and component assemblies targeted to address farm/environment needs. Project outcomes should help dairy farms to make better-informed decisions about manure/nutrient management systems.

Societal demand for farms to reduce their environmental impact is driving the need for improved and cost-effective manure/nutrient management options. Dairy farms may need advanced manure treatment systems to be economically, environmentally, and societally sustainable.

What Did We Do?

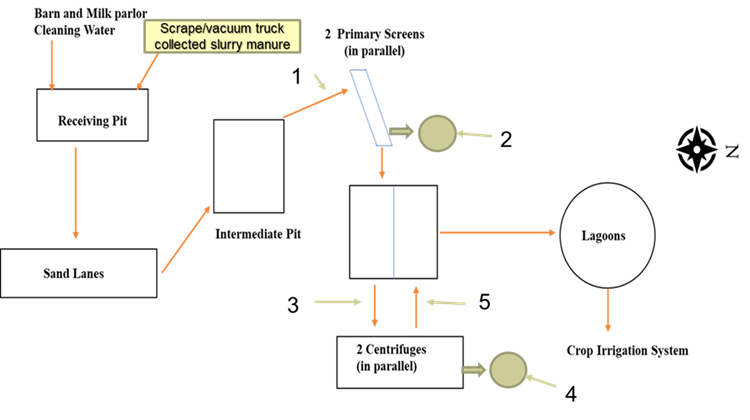

Specific treatments being evaluated include anaerobic digestion, active composting, sequencing batch reactors, solid-liquid separation systems including, screw press separation, dissolved air floatation, centrifuging, and solid treatment systems including bedding recovery units and pelletization. We are working with a farm that has an anaerobic digester and screw press separators. They have been planning to install a Dissolved Air Flotation (DAF) system. The farm was approached with an in-vessel composting technology “active composting” to determine if it could effectively convert portions of the digested separated liquid flow to a stabilized solid that could be pelletized and exported, while the liquids could be further treated to become dilute enough to be spray irrigated on a limited acreage.

What Have We Learned?

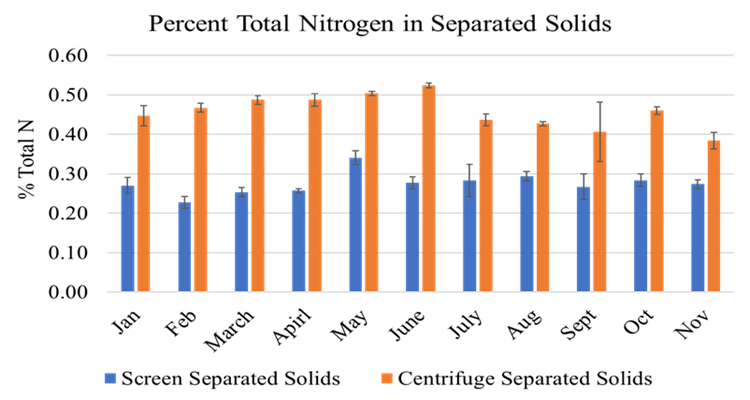

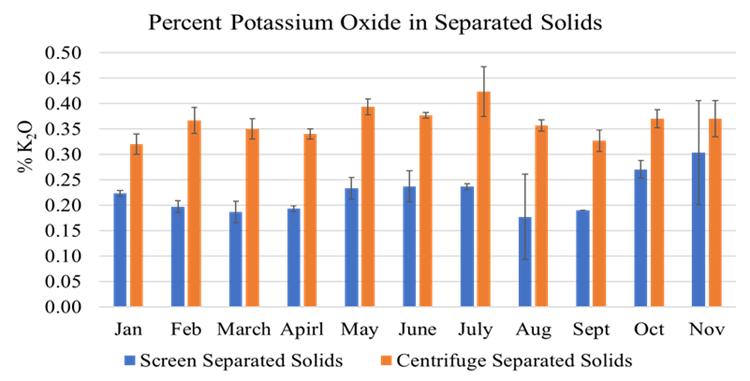

We learned that although the active composting process was able to quickly produce stabilized high solid content material from a variety of mixes of digested separated liquid and dried shavings, the energy needed ranged from $9 to $14 per cow per day. Through volume/time calculations, the pumping system from the reception pit to the digester and the post digestion pit to the separators varied although the % solids were consistent. Doppler flow meters purported to be able to measure manure did not give consistent volume results. Screw press solid liquid separation can result in a bedding product with relatively low moisture (60%) from anaerobically digested dairy manure. Determining an optimum manure treatment system for dairy manure will be difficult given the variability from farm to farm.

Future Plans

Specific treatments yet to be evaluated include: anaerobic sequencing batch reactors, solid liquid separation systems including dissolved air floatation (DAF), centrifuging, and solid treatment systems including bedding recovery units (BRU) and pelletization. Covid supply chain issues and travel restrictions have slowed progress. The DAF system can be directly analyzed as it is installed on the dairy. A neighboring farm has a BRU that will be sampled and analyzed. Data from a centrifuge and pelletizer will be obtained from the literature. Putting the process in a treatment train will be explored on a spreadsheet.

Authors

Peter Wright, Agricultural Engineer, PRO-DAIRY, Cornell University

Corresponding author email address

Additional authors

Lauren Ray, Environmental Energy Engineer, PRO-DAIRY, Cornell University

Curt Gooch, Emeritus Senior Extension Associate, Cornell University

Additional Information

We have completed several fact sheets including Manure Basics, Advanced Manure Treatment – Part 1: Overview, Part 2: Phosphorus recovery technologies, Part 3: Nitrogen recovery technologies, and Part 4: Energy extraction. These are available at: https://cals.cornell.edu/pro-dairy/our-expertise/environmental-systems/manure-management/manure-treatment

Publications: Peter Wright, Karl Czymmek, and Tim Terry “Food waste coming to your farm? Consider where the nutrients go and manure processing for nutrient export” PRO-DAIRY The Manager, contained in Progressive Dairy Vol. 35 No. 5 March 12, 2021

Acknowledgements

This work was supported by a joint research and extension program funded by the Cornell University Agricultural Experiment Station (Hatch funds) and Cornell Cooperative Extension (Smith Lever funds) received from the National Institutes for Food and Agriculture (NIFA,) U.S. Department of Agriculture. Any opinions, findings, conclusions, or recommendations expressed in this publication are those of the author(s) and do not necessarily reflect the view of the U.S. Department of Agriculture. New York State Pollution Prevention Institute (NYSP2I) at the Golisano Institute for Sustainability (GIS) paid for the sampling that was funded by a grant to RIT from by the Environmental Protection Fund as administered by the NYS Department of Environmental Conservation.

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2022. Title of presentation. Waste to Worth. Oregon, OH. April 18-22, 2022. URL of this page. Accessed on: today’s date.