In this mesophilic solid-state anaerobic co-digestion study, interaction among process parameters were investigated. To achieve this, four treatments were considered based on two carbon to nitrogen ratios (34 and 28). The treatments were DMCS34 – Dairy manure, inoculum, and untreated corn stover with C/N ratio of 34; DMCS28 – Dairy manure, inoculum, and untreated corn stover with C/N ratio of 28; DMPCS34 – Dairy manure, inoculum, and washed pretreated corn stover with C/N ratio of 34; and DMPCS28 – Dairy manure, inoculum, and washed pretreated corn stover with C/N ratio of 28. 1500g of each of this treatment was introduced into a 3.5L digester subjected to a temperature of 35oC. Samples from each treatment were analyzed for ADF, NDF, ADL, ORP, pH, volatile fatty acids concentration and composition, alkalinity, and ammonia-nitrogen at the start and end of the experiment. Also monitored and measured was the hydrogen sulphide, methane composition and biogas yield.

What Have We Learned?

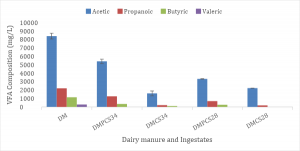

In line with literatures, co-digestion of dairy manure with pretreated or untreated corn stover reduced inhibitory potential of dairy manure. For instance, propionic acid is one of such inhibitory substance to methanogens at 900 mg/L concentration. From Figure 1 propanoic concentration for all the treatments (DMPCS34, DMPCS28, DMCS34, and DMCS28) relative to the dairy manure was significantly reduced by at least 40 % (p < 0.05). Hence, these treatments all had propanoic concentration below 900 mg/L except for DMPCS34. The contrary trend with DMPCS34 treatment might suggest the role of high C/N in propanoic production rate. Furthermore, we also observe that pretreatment lessen this dilution effect, as propanoic concentration was higher with the pretreated treatments (DMPCS34 and DMPCS28).

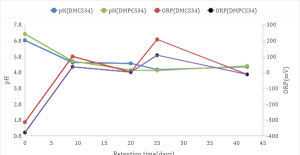

On interaction between ORP relationship with pH, our result shows that there was a strong negative correlation between pH and ORP. As the ORP increases, the pH decreases. This could be attributed to high VFA production beyond the buffering capacity of the alkalinity in the influent. The slight decrease observed in the ORP after 25 days (Figure 2) detention time could be attributed to 33 mL of NaHCO3 added to raise the pH. However, this seems to have no obvious impact on the pH, as the pH remains between 4.8 – 5.2. Similar trend was observed for DMCS28 and DMPCS28 influent with more pronounced ORP increase from between -390 mV at the start of the experiment to +131 mV at the end of the experiment.

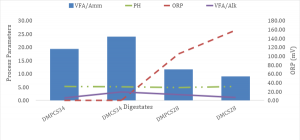

A more complex interaction among VFA/Ammonia, pH, ORP and VFA/Alkalinity investigated in Figure 3 shows low growth in VFA/Alkalinity relative to VFA/Ammonia, an indication that ammonia concentration was low relative to other alkaline in the digester. This might be due to low ammonia mineralization or the generation rate might be slower compared with VFA production rate. Furthermore, at the end of the experiments, the digestates all had VFA/Alkalinity values that exceeded 0.9 (Figure 3), a stable process condition threshold for anaerobic digestion.

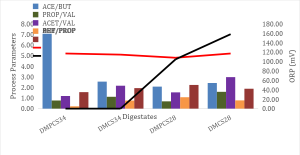

Unlike Figure 3, there was no clear interaction among ORP and VFA composition ratio after the experiment (Figure 4). However, we observed that acetic to propionate acid ratio in our study was above the threshold 0.7 recommended for effective anaerobic digestion. Interestingly, acetic to butyric ratio was inversely proportional to the butyric to propanoic ratio (Figure 4).

Future Plans

We intend to conduct more investigation on these process parameters in order to have a more defined values for a suitable solid-state anaerobic co-digestion process.

Authors

Shafiqur Rahman, Associate Professor, Agricultural & Biosystems Engineering Department, North Dakota State University

Ademola Ajayi-Banji, Graduate Student, Agricultural & Biosystems Engineering Department, North Dakota State University

Additional Information

Will be available at North Dakota State University library by 2020.

Acknowledgements

North Dakota State University Development Foundational Grant.

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2019. Title of presentation. Waste to Worth. Minneapolis, MN. April 22-26, 2019. URL of this page. Accessed on: today’s date.