Purpose

Purpose

Poultry production is a significant source of air pollutant emissions including particulate matter (PM), ammonia (NH3), and pathogens, which negatively impact bird health and performance, human respiratory health, food safety, and local environmental quality. Effective and economically feasible management practices and technologies to mitigate air pollutant emissions and pathogen transmission are urgently needed.

In the past decade, a variety of management practices and control technologies have been developed and preliminarily tested in commercial poultry facilities, with varying degrees of success. Technologies that have been applied for PM control include air filtration, impaction curtains, oil/water spraying, wet scrubbers, electrostatic precipitation, and electrostatic spray scrubbing. Among these, electrostatic methods and wet scrubbing achieve high removal efficiencies for both fine and coarse PM. For NH3 gas mitigation, various forms of scrubbing technologies such as trickling biofilters, acid spray scrubbers, and electrolyzed water spraying have been tested in commercial poultry facilities, alongside management practices such as feed additives and litter amendments. Acid spray scrubbers can be particularly attractive to poultry facilities since the sulfuric acid from the scrubber reacts with NH3 to create ammonium sulfate, which can be used as fertilizer to offset scrubber operating costs. A new technology using artificial floor was recently studied and demonstrated significant reduction in ammonia and PM concentrations and emissions at laying hen housing.

The avian influenza outbreak in 2014/15 and the current spread of the Highly Pathogenic Avian Influenza (HPAI) remind us that pathogen control at poultry facilities is crucial. Technologies such as electrostatic precipitators, electrostatic spray scrubbers, and electrolyzed water spraying systems have been tested to assess their capacities for airborne bacteria reduction.

The technical and economic feasibilities of these methods need to be evaluated for proper consideration by poultry producers and their stakeholders. All the above research results need to be introduced to producers for practical applications.

What Did We Do?

This workshop is organized for the researchers and Extension specialists to review the latest BMPs and BATs on control of dust, ammonia, and pathogens at poultry facilities for improved biosecurity, food safety, environmental quality, and the overall sustainability of poultry production. We have developed the following presentations and will present them at 2022 W2W.

-

- Manure Drying Methods to Control Ammonia Emissions (Dr. Albert Heber-Professor Emeritus, Purdue University)

- A Spray Wet Scrubber for Recovery of Ammonia Emissions from Poultry Facilities (Dr. Lingying Zhao, Professor, Ohio State University)

- Electrostatic Precipitation Technologies for Dust and Pathogen Control at Poultry Layer Facilities (Dr. Lingying Zhao, Professor, The Ohio State University)

- Field Experiences of Large-Scale PM Mitigation (Dr. Teng Lim, Professor, University of Missouri)

- Mitigation of Ammonia and Particulate Matter at Cage-free Layer Housing with New Floor Substrate (Dr. Ji-Qin Ni, Professor, Purdue University)

What Have We Learned?

-

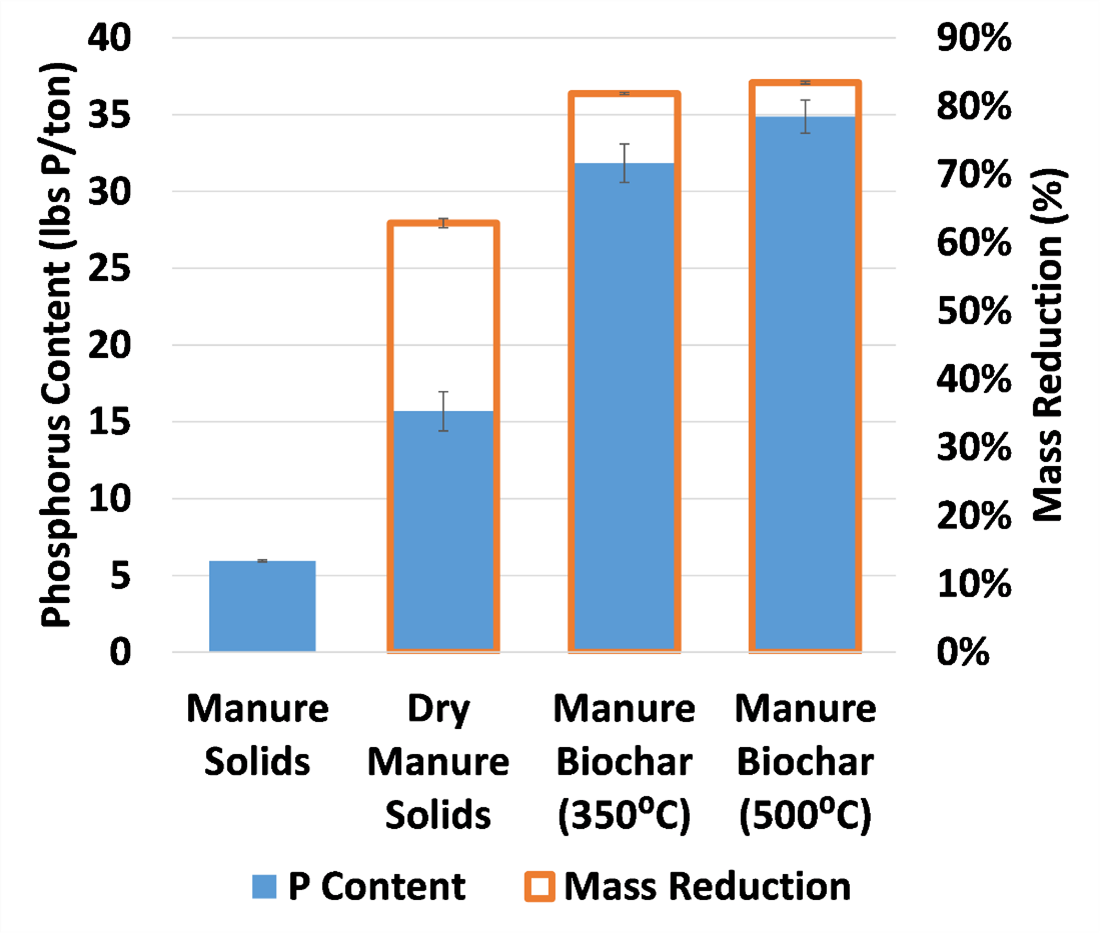

- Newly developed BMPs and BATs can improve air quality in commercial poultry facilities: Manure belt layer houses reduce ammonia emissions by removing manure from the layer houses in 1 to 7 days. Belt aeration using blower tubes is one method that has been used to dry the manure on the belt. Drying tunnels take manure from layer houses and utilize ventilation exhaust air to further dry the manure before it enters the manure storage or compost facilities or transfers to pelletizing operations. Manure sheds and compost facilities are ventilated with building exhaust air or fresh air to dry manure in storage.

- The use of acid spray scrubbing is promising, as it simultaneously mitigates and recovers ammonia emission for fertilizer. Its low contribution of backpressure on propellor fans makes it applicable on US farms. A full-scale acid spray scrubber was developed to recover ammonia emissions from commercial poultry facilities and produce nitrogen fertilizer. The scrubber performance and economic feasibility were evaluated at a commercial poultry manure composting facility that released ammonia from exhaust fans with concentrations of 66–278 ppmv and total emission rate of 96,143 kg yr−1. The scrubber achieved high NH3 removal efficiencies (71–81%) and low pressure drop (<25 Pa). Estimated water and acid losses are 0.9 and 0.04 ml m−3 air treated, respectively. Power consumption rate was between 90 and 108 kWh d−1. The scrubber effluents containing 22–36% (m/v) ammonium sulphate are comparable to commercial-grade nitrogen fertilizer. Preliminary economic analysis indicated that a break-even of one year is achievable. This study demonstrates that acid spray scrubbers can economically and effectively recover NH3 from animal facilities for fertilizer.

- Two types of electrostatic precipitation-based dust control technologies have been developed at the Ohio State University: the electrostatic precipitator (ESP) and the electrostatic spray scrubber (ESS). Field tests of the ESP and ESS conducted at a commercial layer facility indicated that (1) the fully optimized ESP achieved respective mean PM5, PM10, and TSP removal efficiencies of 93.6% ±5.0%, 94.0% ±5.0%, and 94.7% ±4.4% and (2) the ESS exhibited respective mean PM2.5, PM10, and TSP removal efficiencies of 90.5% ±10.0%, 91.9% ±8.2%, and 92.9% ±6.9%. A system of 88 large ESP units to treat exhaust air from the 4-house poultry facility at the minimum required ventilation rate of 24.8 m3 s-1 would have an initial cost of $757,680 and an annual operating cost of $10,831 ($13.43 per 1,000 birds), increasing annual facility electricity consumption by 54.2%. A system of ESS units designed to treat exhaust air for six exhaust fans in each of the 4 poultry houses that operated continuously year-round for minimum ventilation, is estimated to have an initial cost of $71,280 with an annual operating cost of $21,663 for water consumption and electricity usage. The ESP is more effective, and the ESS is more economically feasible to mitigate PM at a commercial egg production facility.

- The field-scale measurements of PM mitigation technologies are usually time-consuming to set up and maintain, and often only limited replications can be obtained. It is important to minimize interference to the routine farm operation. The use of different PM measurements, setup and maintenance required to ensure data quality, and differences between the mitigation technologies are discussed. It is important to consider practicality of the mitigations, along with safety, and long-term use of the different technologies.

- A new mitigation approach, using AstroTurf ® as floor substrate, reduced indoor concentrations and emissions of ammonia and PM at cage-free aviary-style layer rooms in a recent study. Results demonstrated that the average daily mean ammonia concentration in the two AstroTurf® floor rooms (7.5 ppm) was significantly lower (p < 0.05) compared with that in the two wood shaving floor rooms (15.2 ppm) with a reduction rate of 51%. Average daily mean large particles (all particles detected above ~2.5 µm) and small particles (all particles detected below ~0.5 µm) in the two AstroTurf® floor rooms were significantly reduced (p < 0.05) by 70% (501,300 vs. 1,679,700 per ft3) and 63% (906,300 vs. 2,481,100 per ft3), respectively, compared with those in the two wood shaving floor rooms. With the controlled and consistent ventilation rates among the rooms in the study, the emissions of ammonia and PM (large and small particles) from the two AstroTurf® floor rooms had similar reduction rates.

Future Plans

More workshops to review BMPs and BATs for mitigation of air emissions and pathogen transmission in poultry facilities will be organized as new research development and findings emerge. The workshop will target audiences of researchers, farmers, and professionals working with farmers.

Authors

Presenting authors

Lingying Zhao, Professor and Extension Specialist, The Ohio State University

Albert Heber, Professor Emeritus, Purdue University

Teng Lim, Professor, University of Missouri

Ji-Qin Ni, Professor, Purdue University

Corresponding author

Lingying Zhao, Professor and Extension Specialist, The Ohio State University

Corresponding author email address

Zhao.119@osu.edu

Additional authors

Matt Herkins, Graduate Research Associate, The Ohio State University

Albert Heber, Professor Emeritus, Purdue University

Teng Lim, Professor, University of Missouri

Ji-Qin Ni, Professor, Purdue University

Additional Information

Airquality.osu.edu

Hadlocon, L. J., A. Soboyejo, L. Y. Zhao, and H. Zhu. 2015. Statistical modeling of ammonia absorption efficiency of an acid spray scrubber using regression analysis. Biosystems Engineering 132: 88-95.

Hadlocon, L. S., R.B. Manuzon, and L. Y. Zhao. 2015. Development and evaluation of a full-scale spray scrubber for ammonia recovery and production of nitrogen fertilizer at poultry facilities. Environmental Technology 36(4): 405-416.

Hadlocon, L.J. and L.Y. Zhao. 2015. Production of ammonium sulfate fertilizer using acid spray wet scrubbers. Agricultural Engineering International: CIGR Journal. 17 (Special Issue: 18th World Congress of CIGR): 41-51.

Hadlocon, L.J., L.Y. Zhao, B. Wyslouzil, and H. Zhu. 2015. Semi-mechanistic modeling of ammonia absorption in acid spray scrubbers based on mass balances. Biosystems Engineering 136:14-24.

Heber, A. J., T.-T. Lim, J.-Q. Ni, P. C. Tao, A.M. Schmidt, J. A. Koziel, S. J. Hoff, L.D. Jacobson, Y.H. Zhang, and G.B. Baughman. 2006. Quality-assured measurements of animal building emissions: Particulate matter concentrations. Journal of the Air & Waste Management Association. 56(12): 1642-1648.

Knight, R. M. L.Y. Zhao, and H. Zhu. 2021. Modelling and optimisation of a wire-plate ESP for mitigation of poultry PM emission using COMSOL. Biosystems Engineering 211: 35-49.

Knight, R., X. Tong, L. Zhao, R. B. Manuzon, M. J. Darr, A. J. Heber, and J. Q. Ni. 2021. Particulate matter concentrations and emission rates at two retrofitted manure-belt layer houses. Transactions of the ASABE 64(3): 829-841. (doi: 10.13031/trans.14337)

Knight, R., X. Tong, Z. Liu, S. Hong, and L.Y. Zhao. 2019. Spatial and seasonal variations of PM concentration and size distribution in manure-belt poultry layer houses. Transactions of the ASABE 62(2):415-427. doi: 10.13031/trans.12950

Lim, T. T., H. W. Sun, J.-Q. Ni, L. Zhao, C. A. Diehl, A. J. Heber, and P.-C. Tao. 2007. Field tests of a particulate impaction curtain on emissions from a high-rise layer barn. Transactions of the ASABE 50(5): 1795-1805.

Lim, T.-T., Y. Jin, Ni, J.-Q., and A. J. Heber. 2012. Field evaluation of biofilters in reducing aerial pollutant emissions from commercial finishing barn. Biosytems Engineering 112(3): 192-201.

Lim, T.-T., C. Wang, A. J. Heber, J.-Q. Ni, and L. Zhao. 2018. Effect of electrostatic precipitation on particulate matter emissions from a high-rise layer house. In Air Quality and Livestock Farming, 372 p. T. Banhazi, A. Aland, and J. Hartung, eds. Australia: CRC Press, Taylor and Francis Group.

Ni, J.-Q., A.J. Heber, M. J. Darr, T.-T. Lim, Diehl, and B. W. Bogan. 2009. Air quality monitoring and on-site computer system for livestock and poultry environment studies. Transactions of the ASABE 52(3): 937-947.

Ni, J.-Q., A. J. Heber, E. L. Cortus, T.-T. Lim, B. W. Bogan, R. H. Grant, and M. T. Boehm. 2012. Assessment of ammonia emissions from swine facilities in the U.S. – Application of knowledge from experimental research. Environmental Science & Policy 22(0): 25-35.

Ni, J.-Q., L. Chai, L. Chen, B. W. Bogan, K. Wang, E. L. Cortus, A. J. Heber, T.-T. Lim, and C. A. Diehl. 2012. Characteristics of ammonia, hydrogen sulfide, carbon dioxide, and particulate matter concentrations in high-rise and manure-belt layer hen houses. Atmospheric Environment 57(0): 165-174.

Ni, J.-Q., S. Liu, C. A. Diehl, T.-T. Lim, B. W. Bogan, L. Chen, L. Chai, K. Wang, and A. J. Heber. 2017. Emission factors and characteristics of ammonia, hydrogen sulfide, carbon dioxide, and particulate matter at two high-rise layer hen houses. Atmospheric Environment 154: 260-273. http://dx.doi.org/10.1016/j.atmosenv.2017.01.050.

Tong, X., L.Y. Zhao, A. Heber, and J. Ni. 2020. Mechanistic modelling of ammonia emission from laying hen manure at laboratory scale. Biosystems Engineering. 192:24-41.

Tong, X., L.Y. Zhao, A. Heber, and J. Ni. 2020. Development of a farm-scale, quasi-mechanistic model to estimate ammonia emissions from commercial manure-belt layer houses. Biosystems Engineering 196, 67-87.

Tong, X., L.Y. Zhao, R. B. Manuzon, M. J. Darr, R. M. Knight, C. Wang, A. J. Heber, and J.Q. Ni. 2021. Ammonia concentrations and emissions at two commercial manure-belt layer housed with mixed tunnel and cross ventilation. Transactions of the ASABE 64(6): 2073-2087. (doi: 10.13031/trans.14634)

Tong, X., S. S. Hong., and L.Y. Zhao 2019. Development of upward airflow displacement ventilation system of manure-belt layer houses for improved indoor environment using CFD simulation. Biosystems Engineering 178:294-308.

Zhao, L.Y., L. J. S. Hadlocon, R. B. Manuzon, M.J. Darr, H. M. Keener, A. J. Heber, and J.Q. Ni. 2016. Ammonia concentrations and emission rates at a commercial manure composting facility. Biosystems Engineering 150: 69-78.

Acknowledgements

The wet scrubber development was supported by National Research Initiative Competitive Grant 2008-55112-1876 from the USDA Cooperative State Research, Education, and Extension Service Air Quality Program. The ammonia emission modelling work was supported by the USDA-NIFA Grant 2018-67019-27803.

The electrostatic precipitation-based dust control work was supported by the USDA National Institute of Food and Agriculture Grant 2016-67021-24434.

The Project funding for the Mitigation of Ammonia and Particulate Matter at Cage-free Layer Housing with New Floor Substrate presentation was provided by the U.S. Poultry & Egg Association. GrassWorx LLC provided the AstroTurf and financed the building of the flooring systems.

Appreciation is also expressed to the U.S. EPA, and participating producers and staff for their collaboration and support.

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2022. Title of presentation. Waste to Worth. Oregon, OH. April 18-22, 2022. URL of this page. Accessed on: today’s date.

Purpose

Purpose