Waste to Worth home | More proceedings….

Waste to Worth home | More proceedings….

Abstract

In recent years, processing agricultural by-products to produce energy has become increasingly attractive due to several reasons: centralized availability of low cost by-products, avoiding the fuel vs. food debate, reduction of some associated environmental impacts, and added value that has the potential to generate additional income for producers. Anaerobic digestion systems are one waste-to-energy technology that has been proven to achieve these objectives. However, investigation on the impacts of anaerobic digestion has focused on defined segments, leaving little known about the impacts that take place across the lifecycle. Current systems within the U.S. are dairy centric with dairy manure as the most widely used substrate and electricity production as the almost sole source for biogas end use. Recently, there is more interest in exploring alternative feedstocks, co-digestion pathways, digestate processing, and biogas end uses. Different operational and design practices raise additional questions about the wide reaching impacts of these decisions in terms of economics, environment, and operational aspects, which cannot be answered with the current state of knowledge.

Why Study the Life Cycle of Anaerobic Digestion?

Waste management is a critical component for the economic and environmental sustainability of the agricultural sector. Common disposal methods include land application, which consumes large amounts of land resources, fossil energy, and produces significant atmospheric GHG emissions. Proof of this is that agriculture accounts for approximately 50% of the methane (CH4) and 60% of the nitrous oxide (N2O) global anthropogenic emissions, being livestock manure one of the major sources of these emissions (Smith et al., 2007). In the last decades, the development of anaerobic digestion (AD) systems has contributed to achieve both climate change mitigation and energy independence by utilizing agricultural wastes, such as livestock manure, to produce biogas. In addition, it has been claimed that these systems contribute to nutrient management strategies by adding flexibility to the final use and disposal of the remaining digestate. Despite these advantages, the implementation of AD systems has been slow, due to the high investment and maintenance costs. In addition, little is still known about the lifecycle impacts and fate and form of nutrients of specific AD systems, which would be useful to validate their advantages and identify strategic and feasible areas for improvement.

The main goal of this study is to quantify the lifecycle GHG emissions, ammonia emissions, net energy, and fate and form of nutrients of alternative dairy manure management systems including land-spread, solid-liquid separation, and anaerobic digestion. As cow manure is gaining an important role within the biofuel research in the pursuit for new and less controversial feedstocks, such as corn grain, the results of this study will provide useful information to researchers, dairy operators, and policy makers.

What Did We Do?

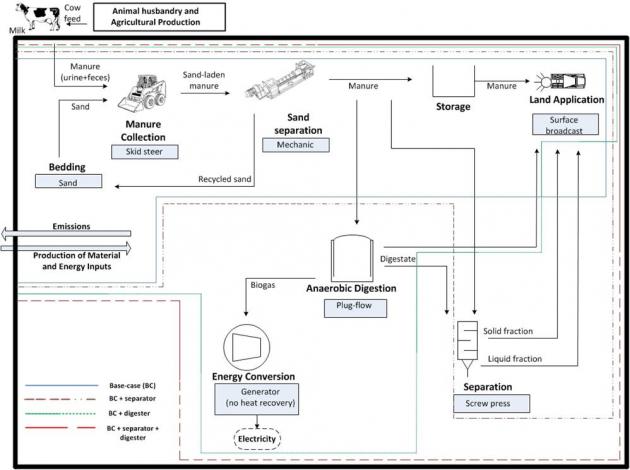

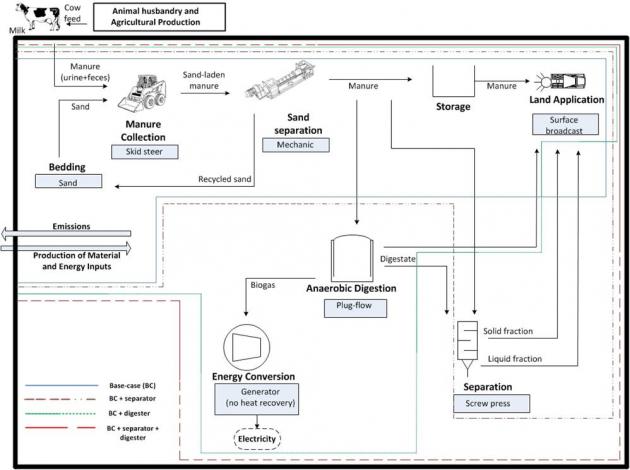

Lifecycle sustainability assessment (LCSA) methods were used to conduct this research, which is focused in Wisconsin. The state has nearly 1.3 million dairy cows that produce approximately 4.7 million dry tons of manure annually and is the leading state for implemented agricultural based AD systems. Manure from a 1,000 milking cow farm (and related maintenance heifers and dry cows) was taken as the base-case scenario. Four main processes were analyzed using the software GaBi 5 (PE, 2012) for the base case: manure production and collection, bedding sand-separation, storage, and land application. Three different manure treatment pathways were compared to the base-case scenario: including a solid-liquid mechanical separator, including a plug-flow anaerobic digester, and including both the separator and the digester. The functional unit was defined as one kilogram of excreted manure since the function of the system is to dispose the waste generated by the herd. A cradle-to-farm-gate approach was defined, but since manure is considered waste, animal husbandry and cultivation processes were not included in the analysis (Fig. 1). Embedded and cumulative energy and GHG emissions associated with the production of material and energy inputs (i.e. sand bedding, diesel, electricity, etc.) were included in the system boundaries; however, the production of capital goods (i.e. machinery and buildings) were excluded.

Figure 1. System boundaries of the base case scenario (land-spread manure) and the three manure treatment pathways: 1) solid-liquid separation, 2) anaerobic digestion, 3) anaerobic digestion and solid-liquid separation. |

Global warming potential (GWP) was characterized for a 100-year time horizon and measured in kg of carbon dioxide equivalents (CO2-eq). Characterization factors used for gases other than CO2 were 298 kg CO2-eq for N2O, 25 kg CO2-eq for abiotic CH4 based on the CML 2001 method, and 24 kg CO2-eq for biotic CH4. CO2 emissions from biomass are considered to be different from fossil fuel CO2 emissions in this study; the former recycles existing carbon in the system, while the latter introduces new carbon into the atmosphere. In this context, it will be assumed that CO2 emissions from biomass sources were already captured by the plant and will not be characterized towards GWP[1]. This logic was applied when characterizing biogenic methane as one CO2 was already captured by the plant, therefore, reducing the characterization factor from 25 kg CO2-eq to 24 kg CO2-eq. Even though ammonia (NH3) does not contribute directly to global warming potential, it is considered to be an indirect contributor to this impact category (IPCC, 2006).

Data was collected from different sources to develop lifecycle inventory (LCI) as specific to Wisconsin as possible, in order to maximize the reliability, completeness, and representativeness of the model. The following points summarize some of the data sources and assumptions used to construct the LCI:

- Related research (Reinemann et al., 2010): This model provided data about animal husbandry and crop production for dairy diet in Wisconsin.

- Manure management survey: The survey, sent to dairy farms in Wisconsin, has the objective of providing information related to manure management practices and their associated energy consumption.

- In house experiments: laboratory experiments, conducted at the University of Wisconsin-Madison, provided characterization data about manure flows before and after anaerobic digestion and solid-liquid separation and manure density in relation to total solids (Ozkaynak and Larson, 2012).

- Material and energy databases: National Renewable Energy Laboratory U.S. LCI dataset (NREL, 2008), PE International Professional database (PE, 2012), and EcoInvent (EcoInvent Center, 2007), which are built into GaBi 5. The electricity matrix used in this LCA represents the mix of fuels that are part of the electric grid of Wisconsin.

- Representative literature review.

Biotic emissions from manure have been cited to be very site specific (IPCC, 2006) and even though the Intergovernmental Panel on Climate Change (IPCC) provides regional emission factors, they are only for CH4 and N2O. Specific GHG emission factors were developed for Wisconsin based on the Integrated Farm System Model (IFSM) (Rotz et al., 2011), and by using key parameters that affect emissions (e.g. temperature, volatile solids, manure management practices) for each stage of the manure management lifecycle.

What Have We Learned?

Emissions are produced from consumed energy and from manure during each stage of the manure management lifecycle. In the base-case scenario, manure storage is the major contributor to GHG emissions. In this scenario, a crust tends to form on top of stored manure due to the higher total solids content when compared to digested manure and the liquid fraction of the separated manure. The formation of this crust affects overall GHG emissions (e.g. crust formation will increase N2O emissions but reduce CH4 emissions). The installation of a digester reduces CH4 emissions during storage due to the destruction of volatile solids that takes place during the digestion process. However, some of the organic nitrogen changes form to ammoniacal nitrogen, increasing ammonia and N2O emissions posterior to storage and land application. Energy consumption increases with both anaerobic digester and separation, but net energy is higher with anaerobic digestion due to the production of on-farm electricity. The nutrient balance is mostly affected by the solid-liquid separation process rather than the anaerobic digestion process.

Future Plans

A comprehensive and accurate evaluation of the lifecycle environmental impacts of AD systems requires assessing the multiple pathways that are possible for the production of biogas, which are defined based on local resources, technology, and final uses of the resulting products. A second goal of this research is to quantify the net GHG and ammonia emissions, net energy gains, and fate of nutrients of multiple and potential biogas pathways that consider different: i) biomass feedstocks (e.g miscanthus and corn stover), ii) management practices and technology choices, and iii) uses of the produced biogas (e.g. compressed biogas for transportation and upgraded biogas for pipeline injection) and digestate (e.g. bedding). This comprehensive analysis is important to identify the most desirable pathways based on established priorities and to propose improvements to the currently available pathways.

Authors

Aguirre-Villegas Horacio Andres. Ph.D. candidate. Department of Biological Systems Engineering, University of Wisconsin-Madison. aguirreville@wisc.edu

Larson Rebecca. Ph.D. Assistant Professor. Department of Biological Systems Engineering, University of Wisconsin-Madison.

Additional Information

-

- Ozkaynak, A. and R.A. Larson. 2012. Nutrient Fate and Pathogen Assessment of Solid Liquid Separators Following Digestion. 2012 ASABE International Meeting, Dallas, Texas, August 2012

References

De Klein C., R. S.A. Novoa, S. Ogle, K. A. Smith, P. Rochette, T. C. Wirth, B. G. McConkey, A. Mosier, and K. Rypdal. 2006. Chapter 11: N2O emissions from managed soils, and CO2 emissions from lime and urea application. In Volume 4: Agriculture, Forestry and Other Land Use. IPCC 2006, 2006 IPCC Guidelines for National Greenhouse Gas Inventories, Prepared by the National Greenhouse Gas Inventories Programme, Eggleston H.S., Buendia L., Miwa K., Ngara T. and Tanabe K. (eds). Published: IGES, Japan.

Ecoinvent Centre.2007. Ecoinvent Eata. v2.0. Ecoinvent Reports No.1-25. Swiss Centre for Life Cycle Inventories. Dübendorf.

National Renewable Energy Laboratory (NREL). 2008. U.S. Life-Cycle Inventory (LCI) Database.

Ozkaynak, A. and R.A. Larson. 2012. Nutrient Fate and Pathogen Assessment of Solid Liquid Separators Following Digestion. 2012 ASABE International Meeting, Dallas, Texas, August 2012

PE International. 2012. Software-systems and databases for lifecycle engineering.

Reinemann D. J., T.H. Passos-Fonseca, H.A. Aguirre-Villegas, S. Kraatz, F. Milani, L.E. Armentano, V. Cabrera, M. Watteau, and J. Norman. 2011. Energy intensity and environmental impact of integrated dairy and bio-energy systems in Wisconsin, The Greencheese Model.

Rotz, C. A., M. S. Corson, D. S. Chianese, F. Montes, S.D. Hafner, R. Jarvis, and C. U. Coiner. 2011. The Integrated Farm System Model (IFSM). Reference Manual Version 3.4. Accessed on Nov, 2012. Available at: http://www.ars.usda.gov/Main/docs.htm?docid=8519

Smith, P., D. Martino, Z. Cai, D. Gwary, H. Janzen, P. Kumar, B. McCarl, S. Ogle, F. O’Mara, C. Rice, B. Scholes, O. Sirotenko. 2007: Agriculture. In Climate Change 2007: Mitigation. Contribution of Working Group III to the Fourth Assessment Report of the Intergovernmental Panel on Climate Change [B. Metz, O.R. Davidson, P.R. Bosch, R. Dave, L.A. Meyer (eds)], Cambridge University Press, Cambridge, United Kingdom and New York, NY, USA.

Acknowledgements

This work was funded by the Wisconsin Institute for Sustainable Agriculture (WISA-Hatch)

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2013. Title of presentation. Waste to Worth: Spreading Science and Solutions. Denver, CO. April 1-5, 2013. URL of this page. Accessed on: today’s date.

![]() Waste to Worth home | More proceedings….

Waste to Worth home | More proceedings….