Purpose

With a rapid increase in global population, food security has become a significant concern. This has led to a significant rise in the demand for protein rich sustainable food. Therefore, worldwide tilapia cultivation is being seen as one of the most economical paths to meet the demand of protein rich food. Moreover, with increasing urbanization and pressing need of nutrient circularity, cost reduction and sustainability has driven the concept of aquaponics system, integrating aquaculture with hydroponics.

Aquaponics has gained significant demand both in the USA and globally and is postulated to reduce overall cost and land footprint, while simultaneously recycling the nutrients in a closed system. Further integration of an anaerobic digestion (AD) system for biogas production using aquaponics waste can make the aquaponic system energy resilient and environmentally sustainable. Therefore, the purpose of this study is to investigate the potential of various aquaponics waste for biogas production, and their fate under co-digestion.

What Did We Do?

In this study, aquaponics waste viz., aquaponic sludge, and lettuce roots and leftover leaves after harvesting were obtained as AD substrate from the aquaponic test bed, running under controlled conditions at Purdue University. A centroid simplex design was created to test the biochemical methane potential (BMP) of the substrate under co-digestion. The BMP test was performed in 1.2-L BMP anaerobic digesters, which have a working volume of 1 L. Dairy manure-based digestate obtained from a continuously running industrial digester was used as an inoculum. For all the test groups, substrate to inoculum ratio was maintained at 1:3. All the test groups were set up in triplicates, and the digesters were incubated in the water bath at 37 °C for 30 days. Biogas volume was measured daily using a syringe method.

What Have We Learned?

The study results showed that the aquaponic sludge and lettuce leaves fed in the anaerobic digesters at a ratio of 50:50 on volatile solids (VS) basis had the highest specific methane yield of 0.525 m3 kg-1 VS. However, the lettuce roots showed an antagonistic effect on co-digestion, giving a specific biogas yield of 0.173 m3 kg-1 VS. The results indicate that enhanced methane yields can be achieved by co-digesting aquaponic sludge with farm residues in an appropriate ratio.

Future Plans

This study is part of a USDA research project to develop sustainable blue food systems driven by integrated aquaponics. Further efforts in AD of aquaponics waste are planned to mitigate the inhibitory effect of lettuce roots on co-digestion, so all aquaponics farm residues can be optimally utilized, simultaneously addressing waste management and generating nutrient-rich digestate as a biofertilizer for aquaponic crops. This approach can transform organic waste from aquaponics and plant harvesting into renewable energy, offsetting external energy needs and reducing the environmental footprint.

Authors

Presenting & corresponding author

Ji-Qin Ni, Professor, Agricultural and Biological Engineering, Purdue University, Jiqin@purdue.edu

Additional authors

Mohit Singh Rana, Postdoctoral Research Associate, Purdue University

Rajesh Nandi, Ph.D. student, Purdue University

Additional Information

Web: https://ag.purdue.edu/department/foodsci/big-project/index.html

Instagram: https://www.instagram.com/whenblueisgreenproject?igsh=MTF5a2xsdmppbWE0

X: https://twitter.com/WBlueIsGreen?_ga=2.200172589.2080482534.1739499225-1469780589.1739498857

Acknowledgements

This research was supported by the intramural research program of the U.S. Department of Agriculture, National Institute of Food and Agriculture, Agriculture and Food Research Initiative grants no. 2023-68012-39001.

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2025. Title of presentation. Waste to Worth. Boise, ID. April 7-11, 2025. URL of this page. Accessed on: today’s date.

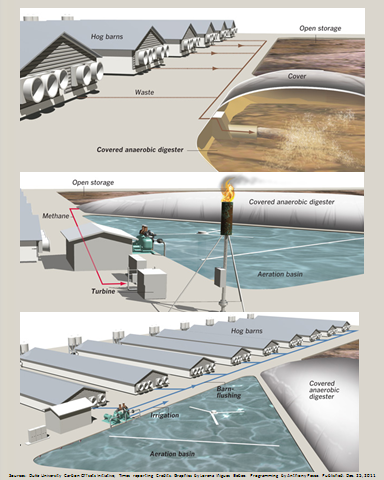

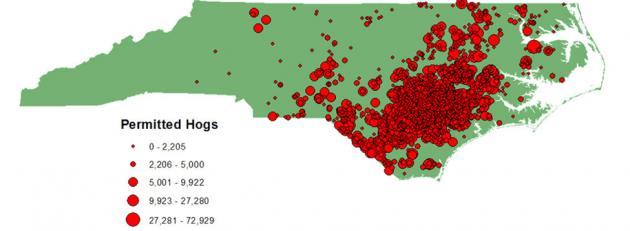

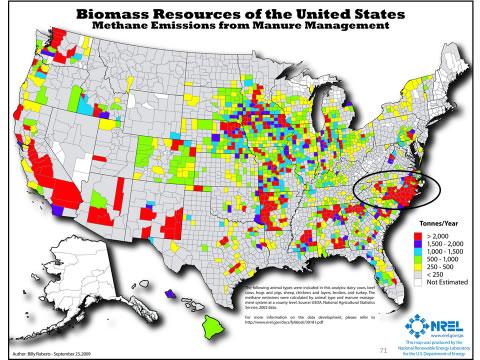

forward-thinking farmers have learned that their waste is valuable for supplying renewable energy, it has been unfortunately difficult for an individual farmer to implement and manage advanced value recovery systems primarily due to costs of scale. Rather, it seems, success may be easier achieved through the aggregation of these products from several farms and through the collaborative efforts of project developers, product offtakers, and policy. A shining example of such aggregation and collaboration can be observed from the Optima-KV swine waste to pipeline renewable gas project, located in eastern North Carolina in an area of dense swine farm population.

forward-thinking farmers have learned that their waste is valuable for supplying renewable energy, it has been unfortunately difficult for an individual farmer to implement and manage advanced value recovery systems primarily due to costs of scale. Rather, it seems, success may be easier achieved through the aggregation of these products from several farms and through the collaborative efforts of project developers, product offtakers, and policy. A shining example of such aggregation and collaboration can be observed from the Optima-KV swine waste to pipeline renewable gas project, located in eastern North Carolina in an area of dense swine farm population. required, which presented challenges of negotiating multiple utility connections and agreements. This learning curve was steepened as, at the time of the inception of Optima KV, the state of North Carolina lacked formal pipeline injection standards, so the final required quality and manner of gas upgrading was established through the development of the project.

required, which presented challenges of negotiating multiple utility connections and agreements. This learning curve was steepened as, at the time of the inception of Optima KV, the state of North Carolina lacked formal pipeline injection standards, so the final required quality and manner of gas upgrading was established through the development of the project.

What did we do?

What did we do?

Future Plans

Future Plans