Purpose

According to the latest estimation of Food and Agriculture Organization of the United Nations, the global dairy cattle stocks reached over 265 million in 2019. The massive stocks of dairy cows excrete an enormous amount of manure, which is a huge burden to the environment if unproperly disposed of, thus necessitating proper manure treatment. As such, anaerobic digestion (AD) has been widely adopted as a practice to manage dairy cattle manure. Within the United States, digesters at dairy farms started to be widely constructed after 2000, and the number of these on-farm digesters in operation or under construction has increased to over 400 in 2024. During the AD treatment of dairy manure, the sulfate-reducing microorganisms are active under anaerobic conditions, therefore high levels of hydrogen sulfide (H₂S) are common in biogas because of the degradation and conversion of sulfur-bearing organics in feeding materials and sulfate-bearing minerals in bedding materials within the manure stream. As an extremely toxic gas with an acute rotten egg odor, H₂S is one of the leading causes of workplace gas inhalation deaths in the US according to the Bureau of Labor Statistics. In addition to the health risks, high H₂S levels can be also very corrosive to the equipment and infrastructure: long-term exposure to concentration of H₂S greater than 1 ppm reduces the lifespan of structural materials, equipment, and electronic devices inside the facilities. Therefore, it is an urgent task to mitigate the H₂S emissions in manure management.

Conventional H₂S removal technologies typically include two categories, namely ex-situ and in-situ. The ex-situ biogas cleaning technologies (e.g., biofilters, aqueous solutions, iron sponge, etc.) require a separate unit to house the facilities and are chemical- and energy-intensive. In-situ H₂S mitigation methods usually require less energy and chemical input as well as an easier operation. In our previous study which employed bio-electrochemical (BEC) treatment concurrently with AD of dairy manure, a H₂S removal efficiency of over 95% was successfully achieved, thus offering a very promising in-situ H₂S remediation method. Nonetheless, it was operated in a continuous mode with electrodes inserted into the digester, which would require significant modification of existing AD systems when scaled up. Therefore, developing new strategies that can advance the application of BEC H₂S remediation within the conventional AD system is critical.

What Did We Do?

Most large sized farms collect liquid manure and slurry in a reception pit (or transition pit) before manure is pumped to the anaerobic digesters. This pit is usually open to the air, thereby offering a great opportunity to integrate the BEC treatment in dairy manure management. In the present lab-scale study, a BEC unit was applied to pretreat the dairy manure collected from the transition pit. On the basis of our previous study, a combination of low carbon steel (LCS) anode and stainless-steel cathode was selected as the electrode pair. At the applied voltages of 1.0-2.5 V, the dairy manure was pretreated for 24 hours prior to AD tests. After the BEC pretreatment, the peak H₂S concentration in the biogas was reduced from approximately 6,000 ppm (in the control without BEC pretreatment) to below 420 ppm in the groups at the applied voltages over 1.5 V. The total H₂S removal efficiencies reached 48.9%, 89.1%, 98.5%, and 100% at 1.0 V, 1.5 V, 2.0 V, and 2.5 V, respectively, equivalent to the sulfide removal of 18.6, 33.4, 36.9, and 37.4 mg S²⁻/g wet dairy manure. Nonetheless, higher voltages did not trigger higher biogas production. Besides, due to the anodic oxidation that released some CO₂ and the precipitation of carbonate (e.g., CaCO₃) in BEC pretreatment, the CH₄ contents in the yielded biogas from BEC groups (64.5-65.6%) were all slightly higher than that from the control (63.4%). Moreover, it was noteworthy that the technical digestion time (T80) (i.e., the time needed to produce 80% of the maximal digester gas production) was shortened to 28.0-29.3 d in the BEC groups at 1.5-2.5 V as compared to 32.8 d in the control. This suggests that the BEC pretreatment can remarkably accelerate biogas production in addition to the H₂S remediation. Groups using non-sacrificial electrodes (e.g., graphite sheets and rods) were also established for the 24-h BEC pretreatment of dairy manure. However, in subsequent AD tests, a large quantity of gaseous H₂S was still emitted. The comparison between the groups with and without sacrificial LCS anodes indicates that the formation of insoluble ferrous sulfide (FeS) was the main route of sulfide removal, whereas the contribution of anodic sulfide oxidation to sulfate and elemental sulfur was relatively limited.

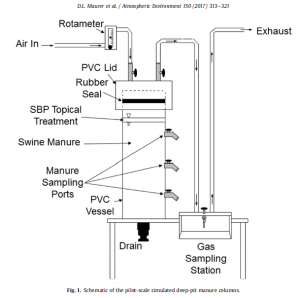

With all the selections and optimizations above, a pilot-scale electrochemical unit was accordingly designed and then installed and operated in the dairy manure pit in a local dairy farm in Minnesota for over two months (as shown in Fig. 1), and its effects in in-situ H₂S remediation in a real application scenario were documented. This pilot-scale BEC system reduced the headspace H₂S level from 1,808 ppb to 390 ppb with a removal efficiency of 78.4%.

What Have We Learned?

This lab-scale success as well as the pilot-scale implementation supports BEC as a promising method for integration into existing on-farm AD systems treating dairy manure. With its incorporation of a BEC unit into the open-air manure transition pit, the operation could be simplified to a large extent without the considerable modification of existing AD systems, whilst the H₂S remediation and the improvement in biogas production (in both CH₄ content and technical digestion time) could be simultaneously achieved at an optimum applied voltage. In summary, this proposed BEC system can successfully reduce the H₂S and improve the safety of a dairy farm during manure storage and treatment.

Future Plans

In our future research, we will further assess the sulfur distribution and microbial community changes after both lab-scale and pilot-scale BEC treatment and also optimize the BEC strategy to reduce anode consumption. Besides, a techno-economic analysis and a life cycle assessment are now under evaluation, based on the data obtained through both the lab-scale tests and the pilot-scale demonstration, to further explore the feasibility and applicability of a full-scale BEC system in a real dairy farm scenario.

Authors

Presenting author

Lingkan Ding, Researcher Pro 5, University of Minnesota

Corresponding author

Bo Hu, Professor, University of Minnesota, bhu@umn.edu

Acknowledgements

The authors greatly appreciate funding support from USDA NRCS Conservation Innovation Grant (NR213A750013G029) and the assistance of Dennis Haubenschild for on-site work on the farm.

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2025. Title of presentation. Waste to Worth. Boise, ID. April 7-11, 2025. URL of this page. Accessed on: today’s date.