![]() Waste to Worth home | More proceedings….

Waste to Worth home | More proceedings….

Why Study Sulfur Emissions and Manure from Animals Fed Distillers Byproducts?

Odorous reduced sulfur compounds are produced during manure decomposition and emitted from confined animal feeding operations. Feeding high-sulfur distiller’s byproducts may increase the emission of these compounds. The objectives of a series of feedlot pen studies was to (i) determine if emissions of reduced sulfur compounds from fresh manure and from the feedlot surface where affected if cattle were fed varying levels of distillers byproducts, and (ii) determine the areas within a pen that emit greater amounts of reduced sulfur compounds.

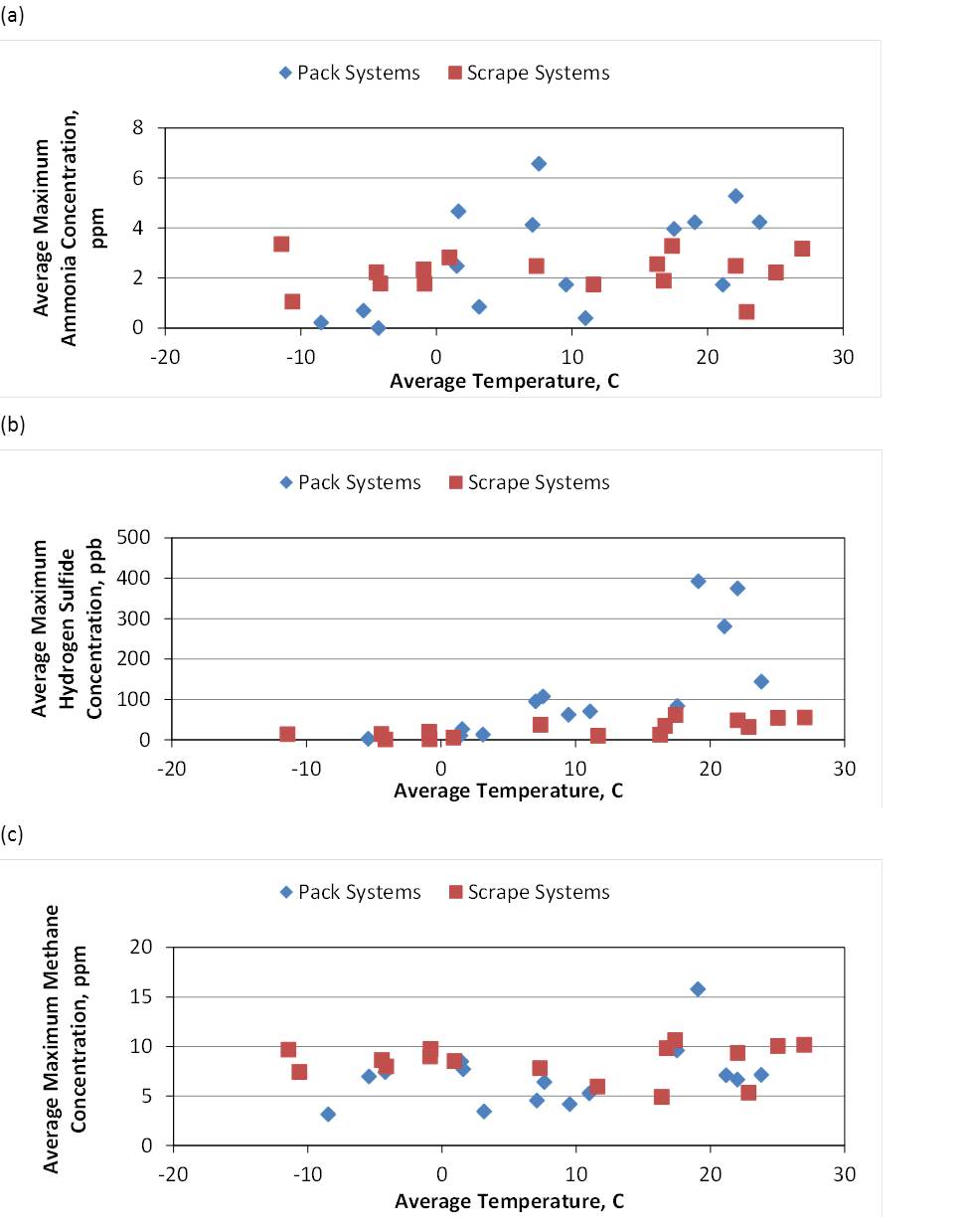

Study #1–Relative emission of redued sulfur compounds from fresh feces. Cattle fed diets containing 0%, 20%, 40%, and 60% WEGS. |

What Did We Do?

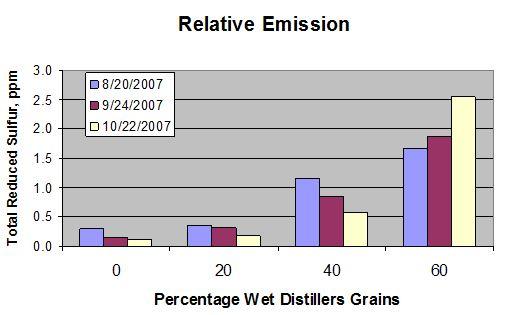

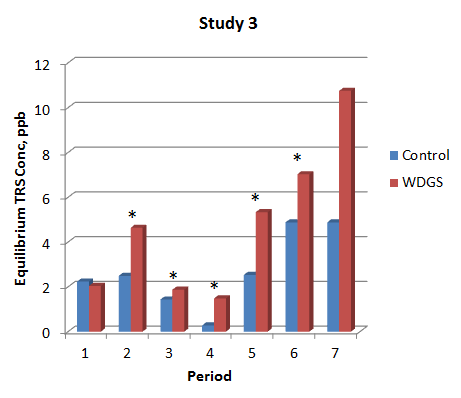

Three studies were conducted to evaluate the relative impact of feeding high-sulfur wet distiller’s grain plus solubles (WDGS) to beef cattle. In the first study, beef cattle in sixteen small-scale pens were fed varying amounts (0%, 20%, 40%, and 60%) of WDGS, and the relative emissions of reduced sulfur from fresh feces were measured using a laboratory wind tunnel chamber. A follow up study in eight production-scale feedlot pens also examined the effect of feeding 0% or 40% WDGS on fresh manure emissions. A third study in ten production-scale pens examined emissions from the pen surface when cattle were fed 0% and 40% WDGS diets over two production cycles.

Study #2–Relative emission of reduced sulfur compounds from feces of cattle fed 0% or 40% WDGS. P values above bars indicate the significance of the difference between emissions on the four dates. |

What Have We Learned?

The relative emission of reduced sulfur from fresh feces was significantly greater (4 to 22-fold) when 40% (or greater) WDGS was fed in the initial study. The follow up study confirmed this finding, but found the relative emission to be lower (2 to 4 fold higher for WDGS) in the production-scale feedlot. In the final study examining the relative emission from the whole feedlot pen surface (mixed soil and aged feces) over many months, emissions principally came from the wetter edges of the pen when animal were fed higher levels of WDGS in their diet. For the six study periods, the relative emissions from WDGS pens ranged from 0.3 to 4-fold higher than a standard ration. Consistent results from these three studies indicate that reduced sulfur emissions increase when animals are fed higher levels of WDGS.

Study #3–Relative concentration of total reduced sulfur (TRS) in the chamber for each of the seven study periods. An asterisk above the bars indicates a significant difference (P < 0.05) between diets. |

Future Plans

The level of sulfur in WDGS varies depending upon source and production method. Feeding lower sulfur WDGS should reduce the relative emission of odorous reduced sulfur compounds. Production of the reduced sulfur compounds may also be related to water quality—some water sources high in sulfur may enhance the emission of reduced sulfur from animal production sites. Further research into the mechanism of reduced sulfur production may provide new insights into controlling the emissions of these odorous compounds.

Authors

Daniel N. Miller, Research Microbiologist, USDA-ARS, Lincoln, NE, dan.miller@ars.usda.gov

Mindy J. Spiehs, Research Animal Scientist, USDA-ARS, Clay Center, NE

Bryan L. Woodbury, Agricultureal Engineer, USDA-ARS, Clay Center, NE

Additional Information

Miller, D. N., V. H. Varel, B. L. Woodbury, and M. J. Spiehs. 2010. Enhanced reduced sulfur emission from manures of beef cattle fed distiller’s byproducts. International Symposium on Air Quality and Manure Management for Agriculture Conference Proceedings, 13-16 September, Dallas, Texas. 711P0510cd.

Acknowledgements

The authors would like to acknowledge the technical expertise of Todd Bowman, Alan Kruger, and Ryan McGhee. Mention of trade names or commercial products in this publication is solely for the purpose of providing specific information and does not imply recommendation or endorsement by the U.S. Department of Agriculture. USDA is an equal opportunity provider and employer.

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2013. Title of presentation. Waste to Worth: Spreading Science and Solutions. Denver, CO. April 1-5, 2013. URL of this page. Accessed on: today’s date.