Purpose

Land application of manure is crucial for providing nutrients to crops, yet challenges such as nutrient losses and reduced nutrient use efficiency (NUE) affect sustainability. This study evaluates a commercially available real-time near-infrared spectroscopy (NIRS) nutrient-sensing system to enhance precision manure nutrient application in crop production systems. The study assesses the impact of the NIRS system on manure application rates, NUE, and crop yield compared to conventional fixed-rate methods.

What Did We Do?

Field trials were conducted using a John Deere Harvest Lab 3000 NIRS system, rate controller, and Krone Flow meter on a manure tanker, Figure 1. Manure was applied to achieve a target total nitrogen rate for corn silage, with application rates varied to simulate manure nutrient variations during lagoon emptying.

What Have We Learned?

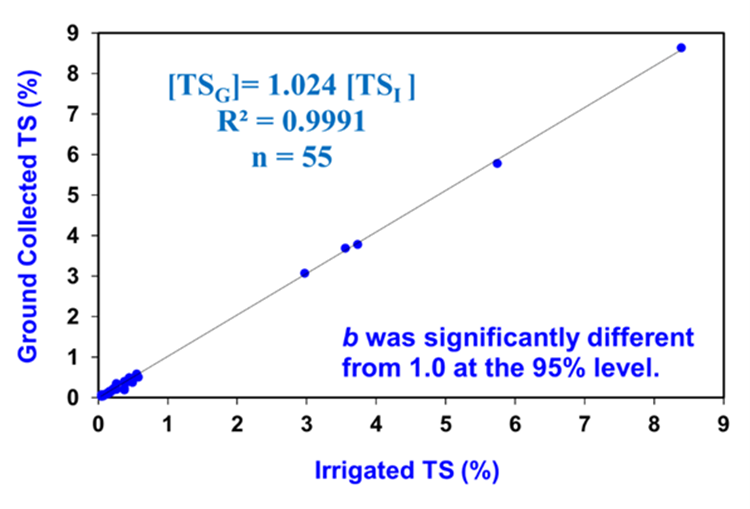

Although NIRS predictions taken in laboratory conditions for total nitrogen were lower than the ranges reported for Manure analysis proficiency (MAP) certified laboratory results, the ammoniacal nitrogen, phosphorous (P2O5), and potassium (K2O) were with the MAP lab ranges reported in Sanford et al. (2020). However, additional data is needed for assessment of the sensor accuracy during field conditions.

First-year field trial data indicate that NIRS was closer to the intended nitrogen application rates and had improved NUE with no significant differences in yield compared to those using conventional fixed-rate application methods. Further, the system is capable of producing manure nutrient application maps that can be used for supplemental nutrient applications, Figure 2.

Overall, integrating NIRS into the land application system demonstrates potential improvements in precision nutrient application over conventional methods. Further trials and analyses are planned to assess the accuracy of the NIRS sensor and its broader impact on nutrient management and application precision.

Future Plans

Researchers plan to continue field trials for another one to two years to assess the impacts over multiple field years. This includes assessing the sensor accuracy in field conditions. Further, researchers’ previous trials have focused on applying based on manure nitrogen content. Additional trials will assess applying manure with a phosphorus limit using the same sensor. Lastly, researchers are working to guide farmers interested in integrating the system and aiding in using developed maps to improve supplemental nitrogen application.

References

Sanford, J.R., R.A. Larson, & M.F. Digman. 2020. Assessing certified manure analysis laboratory accuracy and variability. Applied Engineering in Agriculture, 36(6):905-912. https://doi.org/10.13031/aea.14214

Authors

Presenting author

Tyler Liskow, Engineer, Professor, Nelson Institute for Environmental Studies, University of Wisconsin-Madison

Corresponding author

Rebecca A. Larson, Professor, Nelson Institute for Environmental Studies, University of Wisconsin-Madison, rebecca.larson@wisc.edu

Additional authors

Tyler Liskow, Engineer, Nelson Institute for Environmental Studies, University of Wisconsin-Madison; and Joseph Sanford, Assistant Professor, University of Wisconsin-Platteville

Acknowledgements

This material is based on work that is supported by the National Institute of Food and Agriculture, U.S. Department of Agriculture under award number 2022-69008-36506.

Any opinions, findings, conclusions, or recommendations expressed in this publication are those of the author(s) and do not necessarily reflect the view of the U.S. Department of Agriculture.

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2025. Title of presentation. Waste to Worth. Boise, ID. April 7–11, 2025. URL of this page. Accessed on: today’s date.