This webinar will examine how black soldier fly larvae (BSFL) can transform food and agricultural waste into valuable products for both animal feed and soil health. Presenters will discuss large-scale BSFL production, the frass co-product, and how nutrient content can vary based on inputs and processing. This presentation was originally broadcast on August 15, 2025. Continue reading “Flies, Frass, Feces, and Fields”

Manure processing for discharge water quality – technical performance and county perspectives for advancing water quality

This webinar will examine the potential of advanced manure processing systems to treat manure to water quality standards suitable for discharge. It will feature insights from Dane County Land Conservation, including their objectives in supporting system installation, the ownership and operational structure, financial support mechanisms, observed outcomes, and future planning. This presentation was originally broadcast on June 20, 2025. Continue reading “Manure processing for discharge water quality – technical performance and county perspectives for advancing water quality”

Using ManureTech Decision-Support Tools to Aid in Manure System Selection

Purpose

The purpose of the ManureTech Decision-Support Tools (DST) for Dairy and for Swine is to assist farmers, consultants, and others in the dairy/swine industry in optimizing the management of manure from collection to land application. By providing data-driven recommendations based upon customizable inputs and priorities, the ManureTech DST help users make informed decisions about manure management systems in consideration of the economic, environmental, and operational needs of farm management.

What Did We Do?

A multi-state team has developed Excel-based decision-support tools for selecting technology and systems for managing manure on dairy and swine operations as part of a USDA NIFA-funded project.

During this workshop, participants will be introduced to the ManureTech DST for Dairy and the ManureTech DST for Swine and will be provided with hands-on training in using the decision-support tool for dairy. Major aspects of the tools that will be addressed in the workshop include an introduction to the user interface; entering primary inputs; prioritization of economic, environmental, and operational metrics; and reporting of results, including the ranking of manure system scenarios.

What Have We Learned?

In terms of learning, this effort has provided the project team with a fuller grasp of the complex nature of manure management! In terms of accomplishments, the team has assembled a tool that considers the multi-faceted benefits and challenges of various manure management systems and presents users with a ranked list of systems for consideration, which should help expedite and enhance system selection. Users of the ManureTech DST can provide farm-specific weight to economic, environmental, and operational criteria which allows ManureTech DST to rank alternative manure management scenarios in close alignment with individual priorities.

Future Plans

Future plans include completing beta testing / pilot-testing of the ManureTech DST and conducting additional training on using the tool. Over a longer-range timeframe, the team would like to add some additional specialized capabilities and functionality, as a phase II effort.

Authors

Presenting authors

-

- Erin Scott, Project/Program Manager, University of Arkansas

- Varma Vempalli, Wastewater Treatment Specialist, City of Meridian (ID)

- Jacob Hickman, Systems Analyst, University of Arkansas

- Rick Stowell, Extension Specialist in Animal Environment, University of Nebraska-Lincoln

- Teng Lim, Extension Professor and Engineer, University of Missouri

Corresponding author

Rick Stowell, Extension Specialist in Animal Environment, University of Nebraska-Lincoln, Richard.Stowell@unl.edu

Additional authors

-

- Erin Scott, Project/Program Manager, University of Arkansas

- Jacob Hickman, Systems Analyst, University of Arkansas

- Jennie Popp, Associate Dean and Professor, University of Arkansas

- Varma Vempalli, Wastewater Treatment Specialist, City of Meridian (ID)

- Greg Thoma, Director of Agricultural Modeling and Lifecycle Assessment, Colorado State University

- Teng Lim, Extension Professor and Engineer, University of Missouri

Additional Information

The ManureTech DST and related articles can be accessed at Decision-Support Tools – Livestock and Poultry Environmental Learning Community.

Acknowledgements

The authors acknowledge funding from the USDA NIFA AFRI Water for Food Production Systems program, grant #2018-68011-28691.

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2025. Title of presentation. Waste to Worth. Boise, ID. April 7–11, 2025. URL of this page. Accessed on: today’s date.

Mobilizing Microbes in Treatment Processes

Microbes are abundant in manure and food waste. Harnessing and/or controlling microbial action in a treatment process is challenging – but some technologies are making headway. This webinar will present pilot-scale research for manure and food waste treatment. This presentation was originally broadcast on March 21, 2025. Continue reading “Mobilizing Microbes in Treatment Processes”

Use of Vermifiltration as a Tool for Manure Management

This webinar discusses the science and economics behind the use of worms in the processes of composting (i.e., vermicomposting) and treatment of wastewater and manure liquid waste stream (vermifiltration). This presentation was originally broadcast on May 20, 2022. Continue reading “Use of Vermifiltration as a Tool for Manure Management”

Characterization of Innovative Manure Treatment Components

Purpose

Improvements in manure treatment/nutrient management are an important need for dairy farms to move substantively towards sustainability. This project quantifies several individual manure treatment components and component assemblies targeted to address farm/environment needs. Project outcomes should help dairy farms to make better-informed decisions about manure/nutrient management systems.

Societal demand for farms to reduce their environmental impact is driving the need for improved and cost-effective manure/nutrient management options. Dairy farms may need advanced manure treatment systems to be economically, environmentally, and societally sustainable.

What Did We Do?

Specific treatments being evaluated include anaerobic digestion, active composting, sequencing batch reactors, solid-liquid separation systems including, screw press separation, dissolved air floatation, centrifuging, and solid treatment systems including bedding recovery units and pelletization. We are working with a farm that has an anaerobic digester and screw press separators. They have been planning to install a Dissolved Air Flotation (DAF) system. The farm was approached with an in-vessel composting technology “active composting” to determine if it could effectively convert portions of the digested separated liquid flow to a stabilized solid that could be pelletized and exported, while the liquids could be further treated to become dilute enough to be spray irrigated on a limited acreage.

What Have We Learned?

We learned that although the active composting process was able to quickly produce stabilized high solid content material from a variety of mixes of digested separated liquid and dried shavings, the energy needed ranged from $9 to $14 per cow per day. Through volume/time calculations, the pumping system from the reception pit to the digester and the post digestion pit to the separators varied although the % solids were consistent. Doppler flow meters purported to be able to measure manure did not give consistent volume results. Screw press solid liquid separation can result in a bedding product with relatively low moisture (60%) from anaerobically digested dairy manure. Determining an optimum manure treatment system for dairy manure will be difficult given the variability from farm to farm.

Future Plans

Specific treatments yet to be evaluated include: anaerobic sequencing batch reactors, solid liquid separation systems including dissolved air floatation (DAF), centrifuging, and solid treatment systems including bedding recovery units (BRU) and pelletization. Covid supply chain issues and travel restrictions have slowed progress. The DAF system can be directly analyzed as it is installed on the dairy. A neighboring farm has a BRU that will be sampled and analyzed. Data from a centrifuge and pelletizer will be obtained from the literature. Putting the process in a treatment train will be explored on a spreadsheet.

Authors

Peter Wright, Agricultural Engineer, PRO-DAIRY, Cornell University

Corresponding author email address

Additional authors

Lauren Ray, Environmental Energy Engineer, PRO-DAIRY, Cornell University

Curt Gooch, Emeritus Senior Extension Associate, Cornell University

Additional Information

We have completed several fact sheets including Manure Basics, Advanced Manure Treatment – Part 1: Overview, Part 2: Phosphorus recovery technologies, Part 3: Nitrogen recovery technologies, and Part 4: Energy extraction. These are available at: https://cals.cornell.edu/pro-dairy/our-expertise/environmental-systems/manure-management/manure-treatment

Publications: Peter Wright, Karl Czymmek, and Tim Terry “Food waste coming to your farm? Consider where the nutrients go and manure processing for nutrient export” PRO-DAIRY The Manager, contained in Progressive Dairy Vol. 35 No. 5 March 12, 2021

Acknowledgements

This work was supported by a joint research and extension program funded by the Cornell University Agricultural Experiment Station (Hatch funds) and Cornell Cooperative Extension (Smith Lever funds) received from the National Institutes for Food and Agriculture (NIFA,) U.S. Department of Agriculture. Any opinions, findings, conclusions, or recommendations expressed in this publication are those of the author(s) and do not necessarily reflect the view of the U.S. Department of Agriculture. New York State Pollution Prevention Institute (NYSP2I) at the Golisano Institute for Sustainability (GIS) paid for the sampling that was funded by a grant to RIT from by the Environmental Protection Fund as administered by the NYS Department of Environmental Conservation.

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2022. Title of presentation. Waste to Worth. Oregon, OH. April 18-22, 2022. URL of this page. Accessed on: today’s date.

Active participation in livestock and poultry sustainability initiatives

Purpose

Whether at the farm, integrator or industry level, sustainability programs have unique goals, metrics and approaches. In many cases, there is no definitive path for meeting long-term goals, but in the ambiguity is opportunity. Meeting sustainability goals will take a community of persons on and off farm willing to support measurements, communication and technology development. This session builds on the Livestock and Poultry Environmental Learning Community’s (LPELC) September 2021 Webinar, Industry Initiatives for Environmental Sustainability – a Role for Everyone.

This Waste to Worth workshop features small and large group discussions to identify modes for active participation in livestock and poultry sustainability initiatives.

What Did We Do?

Industry-led sustainability programs are in various stages of charting a destination for environmental metrics, like greenhouse gas emissions, water quality, water use, etc. However, with respect for the range of individual farm resources, climates and systems, there is no prescriptive path.

As farmers and organizations chart their own sustainability journey, there is a need for on-farm baseline metrics, goal setting, and technology guidance. LPELC’s mission is to provide on-demand access to “the nation’s best science-based resources that is responsive to priority and emerging environmental issues associated with animal agriculture” (LPELC.org). The LPELC is in a strong position to share science and support communication efforts. However, like sustainability journeys, LPELC needs a roadmap.

This workshop will illuminate what resources are currently available, knowledge, technology and communication gaps, and how LPELC members can support on-farm sustainability initiatives. Participants will collectively shape a logic model for a “Community of Support for Producer Engagement in Livestock Industry Environmental Sustainability Initiatives”.

What Have We Learned?

A summary of the workshop results will be shared following the conference.

Future Plans

We intend the workshop results to foster stronger networks and collaborative directions for advancing on-farm sustainability initiatives. We aim for short, medium and long-term outcomes that include stronger understanding of current efforts within the livestock industries and LPELC, along with support mechanisms for decision making and funding opportunities.

Authors

Erin Cortus, Associate Professor and Extension Engineer, University of Minnesota

Corresponding author email address

ecortus@umn.edu

Additional authors

Marguerite Tan, Director of Environmental Programs, National Pork Board; Hema Prado, Director of Sustainability, American Egg Board; Michelle Rossman, Vice President – Environmental Stewardship, Dairy Management Inc.

Additional Information

Webinar – Industry Initiatives for Environmental Sustainability – a Role for Everyone https://lpelc.org/industry-initiatives-for-environmental-sustainability-a-role-for-everyone/#more-33017

US Pork Industry Sustainability Goals https://www.porkcares.org/pork-industry-sustainability-goals-and-metrics/

US Roundtable for Sustainable Poultry https://www.us-rspe.org/

US Dairy Net Zero Initiative https://www.usdairy.com/getmedia/89d4ec9b-0944-4c1d-90d2-15e85ec75622/game-changer-net-zero-initiative.pdf?ext=.pdf

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2022. Title of presentation. Waste to Worth. Oregon, OH. April 18-22, 2022. URL of this page. Accessed on: today’s date.

Manure Treatment Technology Adoption by Swine and Dairy Producers: Survey Feedback

Purpose

Sound management of manure is essential to optimize its benefits for soil health and crop production, and to minimize costs and environmental risks. Along with changes in farm scale and practices, modern farms are increasingly looking to process or treat manure to address problem areas and to take advantage of market opportunities on their operations. A variety of manure treatment technologies are available and new technologies continue to be developed for managing nutrients, solids, energy, water, and other components of manure. But, while these new treatment technologies hold potential to improve the environmental, economic, and social sustainability of livestock and poultry production, questions remain regarding producer adoption of treatment systems on their operations. To improve our understanding of decision-making processes employed when producers evaluate and adopt manure treatment technologies, the authors conducted a survey aimed at dairy and swine producers in the Midwest.

What did we do?

Two surveys were developed, one tailored to dairy producers and one for swine producers. All operation sizes and production systems were included. The surveys were administered using Qualtrics, an online survey platform. Questions asked covered manure-related practices in animal facilities, manure handling, and land application. Additional questions asked producers to prioritize their needs for manure treatment, factors influencing technology selection, current technologies being utilized, and principal barriers for adoption. Respondents were asked to select up to three critical outcomes for their farms’ manure treatment technologies, the most influential factors (or technology characteristics) for manure treatment adoption, and the main barriers for technology adoption. The authors collaborated with Nebraska Extension and with state producer associations to reach swine and dairy producers in Nebraska and other Midwest states, with the survey first launched in the fall of 2021. Magazine articles, radio programs, listservs, and social media were used to promote the surveys.

Responses were analyzed using descriptive methods. Eighteen respondents provided information to characterize seven swine farms and ten dairy operations. Swine respondents had farms in Nebraska (7), Iowa (2), and Ohio (1). For dairy, 7 of the farms were in Nebraska and 1 was in Minnesota. Swine farm systems were divided between the ones that had farrowing (farrow-to-finish and farrow-to-wean systems) and the ones without it (grow-to-finish and wean-to-finish systems) (Table 1). Respondents were asked to provide insights for their farms’ primary manure management systems. A dairy operation’s primary manure management system was defined as the one receiving manure from the lactating cows. For swine, the primary manure management system received manure from the gestation sows or the finishing herd. For both swine and dairy, secondary systems were defined as utilizing separate storage and handling facilities.

| Species and herd type | Number of farms | Herd size – average | Herd size – range |

|---|---|---|---|

| Dairy – lactating cow herd | 8 | 933 | 30 to 2,150 |

| Swine (farrowing) – sow herd | 4 | 2,762 | 250 to 7,500 |

| Swine (finishing) – finisher herd | 5* | 23,600 | 1,200 to 70,000 |

| Note: *One finishing farm did not share its herd size information. | |||

What have we learned?

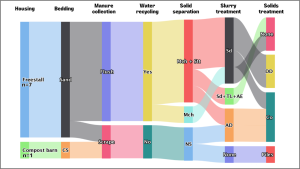

The dairy and swine farms demonstrated differences in manure treatment needs and consequently adopted different treatment technologies (Figures 1 and 2).

FTF = farrow-to-finish

PSOP = partially slotted open pens

PP = pull-plugs

FTW = farrow-to-wean

ISWPSF = individual stalls w/partial slotted floor

DP = deep pits

GF-F = grow-finish or finishing

ASFB = all slotted-floor building

FL = flushing

WTF = wean-to-finish

CH = chemicals

AE = aeration

LA = lagoons

AD = anaerobic digestion

CO = composting

CS = corn stalks

Sd = sedimentation

DD = direct drying

Mch = mechanical

TL = treatment lagoon

Co = composting

Stt = sand settling lane or basin

AE = aeration

NS = no separation

AD = anaerobic digestion

The most-used technologies in the primary manure management system for each industry were: mechanical separation, sand settling lanes, and sedimentation basins for dairy farms; and addition of chemicals, treatment lagoons, and composting for swine operations (Figure 3).

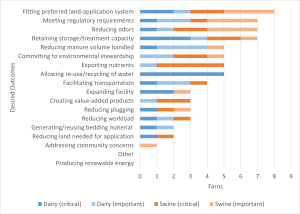

Allowing water to be reused and exporting nutrients were the primary desired outcomes of implementing manure treatment technologies for dairy and swine farms, respectively (Figure 4). Accordingly, 6 of 7 dairy farms were recycling water in their operations, while only 1 out of 10 was doing so on the swine side.

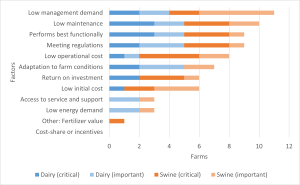

Diverse factors influenced the selection of the implemented technologies in both livestock operations. Low management demand, low maintenance, “performs best functionally” (best performance achieving the desired goals of manure treatment), and low initial cost are among the most-mentioned factors (Figure 5).

Swine and dairy farmers identified initial cost, operational cost, and return on investment as the primary barriers to future technology adoption (Figure 6). Management demand was another important barrier among swine producers.

None of the survey respondents used membranes, electrochemical precipitation, or gasification technologies, demonstrating that cutting-edge manure treatment technologies are being more slowly adopted by regional livestock producers. The high cost and potential high management demand of these technologies could be barriers for their adoption.

Future plans

Our research work has moved into qualitative exploration. Focus groups will be held with swine and dairy producers, where they will discuss and share their manure treatment needs and desired outcomes from new treatment options. These activities will be organized online and will allow producers to share their manure management perspectives for the present and future. The results of our surveys and focus groups are being used to inform a decision-support tool being developed as part of the Management of Nutrients for Reuse (MaNuRe) project. Our findings will also be used to help develop extension programs that meet the needs of producers for manure management in Nebraska and neighboring states.

Authors

Juan Carlos Ramos Tanchez, Graduate Research Assistant, University of Nebraska-Lincoln.

Corresponding author email address

jramostanchez2@huskers.unl.edu

Additional authors

Richard Stowell, Professor of Biological Systems Engineering, University of Nebraska-Lincoln.

Amy Schmidt, Associate Professor of Biological Systems Engineering, University of Nebraska-Lincoln.

Acknowledgements

Funding for this effort came from the USDA NIFA AFRI Water for Food Production Systems program, grant #2018-68011-28691. The authors would like to express gratitude to Dr. Teng Lim and Timothy Canter (University of Missouri), Mara Zelt, and Lindsey Witt-Swanson (University of Nebraska-Lincoln) for their relevant support to this study. We would also like to thank the staff at the Nebraska Pork Producers Association and the Nebraska State Dairy Association for their collaboration on our research.

Cleanout for Lagoons and Anaerobic Digesters

In this webinar, presenters share their expertise in sampling and cleanout for lagoons and anaerobic digesters and considerations in planning these operations. This presentation was originally broadcast on January 21, 2022. Continue reading “Cleanout for Lagoons and Anaerobic Digesters”

California’s Efforts to Reduce Greenhouse Gases from Dairy and Livestock Operations

This webinar discusses two programs in California, administered through the California Department of Food and Agriculture (CDFA), that provide financial incentives to dairy and livestock producers to reduce methane emissions from on-farm manure management. This presentation was originally broadcast on August 16, 2019. More… Continue reading “California’s Efforts to Reduce Greenhouse Gases from Dairy and Livestock Operations”