Responsible manure management uses multiple data types from a wide range of sources. This webinar highlights three new tools that aim to ease this burden while supporting effective decision-making. ManureDB aggregates U.S. manure analysis data and provides user-specified reports of manure characteristics. ManureTech synthesizes the environmental, economic and operational facets of manure treatment technologies. Manure Management Planner is a trusted tool but has also undergone recent updates for site-specific setback distances. Participants will be able to see these tools in action, and where further developments are headed. This presentation was originally broadcast on February 16, 2024. Continue reading “Upcoming Models and Tools to Improve Manure Management”

Agronomic Response to Struvite as an Alternative Fertilizer-phosphorus Source

Purpose

As a primarily mined material, the global reserve of phosphorus (P) is finite and running out. Consequently, inorganic, commercial fertilizers are becoming more expensive. Chemical engineering techniques have been developed and are being actively researched to recover P from wastewater sources in the form of struvite (MgNH4PO4 · 6H2O). Many wastewaters contain elements such as P and nitrogen (N) in various forms that could be recovered and beneficially recycled as fertilizer nutrients. Recovering nutrients, such as P, from wastewaters and/or treating wastewaters to the point they could be safely recycled back into the environment could have a tremendously positive impact on any agricultural activity as well as receiving waters.

Arkansas has a documented significant geographic nutrient imbalance, where the row-crop-dominated region of eastern Arkansas has a severe nutrient deficiency, particularly for P, which routinely requires commercial P applications to supply crop needs for optimum production. Thus, eastern Arkansas is an ideal setting for testing the effectiveness of recovered nutrients from wastewaters as fertilizer sources, especially P, for various row crops, namely rice, corn, and soybeans. A sustainable, wastewater-recovered source of P, in the form of the mineral struvite, would be a critical advancement in the long-term viability of P availability, P-source options, and use as a fertilizer in P-deficient soils used for crop production.

What Did We Do?

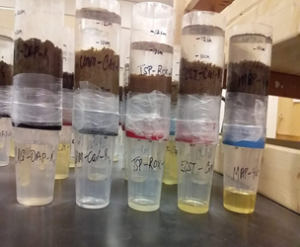

Various studies were conducted to evaluate the behavior of struvite in different soils and crop response to struvite as compared to other commonly used, commercially available fertilizer-P sources [i.e., monoammonium phosphate (MAP), diammonium phosphate (DAP), triple superphosphate (TSP), and rock phosphate (RP)]. Two struvite materials were tested, a chemically precipitated struvite (CPST) created from real wastewater treatment plant effluent and an electrochemically precipitated struvite (ECST) created in the laboratory with an innovative electrochemical approach.

In the laboratory, a series of plant-less soil incubation experiments were conducted in several different agricultural soils to evaluate the behavior of struvite and the other fertilizer-P sources as they solubilize. Soil pH, water-soluble and plant-available P, magnesium (Mg), calcium (Ca), iron (Fe), nitrate and ammonium concentrations were measured over a 4- to 9-month period in moist/aerobic and saturated/flooded/anaerobic soil conditions (Figure 1). A column study was also conducted to evaluate the effects of fertilizer-P source, including ECST and CPST, on P-leaching characteristics over time in multiple soils (Figure 2).

Additionally, a rainfall-runoff simulation experiment was conducted to evaluate the effects of water source (i.e., rainfall, groundwater, and struvite-removed wastewater) and fertilizer-P source on runoff water quality parameters (i.e., pH, electrical conductivity, and P, N, Mg, Ca, and Fe concentrations) in various soils (Figure 3).

In the greenhouse, several potted-plant studies were conducted for 60-90 days evaluating above- and below-ground plant response to ECST, CPST, MAP, DAP, TSP, RP, and unamended controls in rice, corn, soybeans, and wheat. Studies were also conducted to evaluate the effects of fertilizer-P source (i.e., ECST, CPST, DAP, TSP, and an unamended control) on greenhouse gas emissions (i.e., CO2, CH4, and N2O) from flood- and simulated-furrow-irrigated rice (Figure 4).

In the field, two-year studies have been conducted in soil having low soil-test-P to evaluate the effects of fertilizer-P source (i.e., ECST, CPST, MAP, DAP, TSP, RP, and an unamended control) on above- and below-ground dry matter and tissue P, N, and Mg concentrations, aboveground tissue P, N, and Mg accumulations, and yields in rice, corn, and soybeans, as well as soil P concentrations in corn and soybeans (Figure 5).

What Have We Learned?

For the moist-soil incubations, averaged across fertilizer sources, differences in water-soluble soil P concentration [from their initial concentrations] differed among soils over time and, averaged across soils, among fertilizer sources over time. In addition, averaged across time, Mehlich-3-extractable soil P concentration differences from their initial concentrations differed among fertilizer sources within soils. For the flooded-soil incubations, averaged across fertilizer sources, the change in soil pH from the initial differed among soils over time. In addition, averaged across soils, the change in water-soluble soil P concentration from the initial differed among fertilizer sources over time. Results from the plant-less soil incubation experiments show that many elemental soil concentrations, namely P, and soil pH differed among soil-fertilizer-P-source combinations over time. However, in general, the two struvite materials (ECST and CPST) behaved similarly to one another and behaved similarly to at least one other commonly used, commercially available fertilizer-P source without any large, unexpected outcomes across several different agricultural soils with varying soil textures. Struvite appears to relatively similar soil behavior as other commercially available fertilizer-P sources.

For the greenhouse study, no differences were identified in soybean plant properties. However, corn plant properties and corn and soybean elemental tissue concentrations differed (P < 0.05) among fertilizer amendments. Total corn dry matter from ECST did not differ from that from RP and TSP and was 1.2 times greater than that from CPST Belowground corn dry matter from ECST was 1.9 times greater than that from CPST, TSP, DAP, and the unamended control treatments Corn cob-plus-husk dry matter from CPST and ECST were similar. Corn belowground tissue P concentration from CPST did not differ from that from DAP, TSP, and MAP and was 1.4 times larger than that from ECST. Corn cob-plus-husk tissue P concentration from ECST was similar to that from MAP and DAP and was 1.2 times larger than that from CG. Corn stem-plus-leaves tissue P concentration from ECST differed from that from all other treatments and was 1.8 times greater than that from the unamended control. Struvite appears to be a viable, alternative fertilizer-P source.

For the 2019 rice field study, neither above- or belowground P, Mg, and N tissue concentrations differed among fertilizer sources. For the 2019 corn field study, neither above- or below-ground P, Mg, and N tissue concentrations differed among fertilizer sources. For the 2019 soybean field study, neither aboveground Mg or N nor belowground P, Mg, and N tissue concentrations differed among fertilizer sources. However, aboveground tissue P concentration was greater from ECST than from RP and the unamended control. For the 2020 rice field study, aboveground dry matter and aboveground dry matter P, N, Mg concentrations did not differ among fertilizer sources. However, rice grain yield from ECST was similar to that from CPST, but both were lower than from TSP. Aboveground Mg uptake from ECST was greater than that from CPST. For the 2020 corn field study, total aboveground, cob/husk, and stalk/leaves dry matter, aboveground P, N, and Mg concentrations and uptake, and belowground P and N concentrations did not differ among fertilizer sources. However, corn yield was larger from ECST than from all other fertilizer treatments, which did not differ among themselves. Belowground Mg concentration was numerically largest from ECST among all fertilizer-P treatments and was significantly greater than that from MAP, DAP, and TSP. For the 2020 soybean field study, neither aboveground dry matter nor yield differed among fertilizer sources. Similar to greenhouse results, struvite appears to be a viable, alternative fertilizer-P source for multiple agronomic crops, including rice, corn, and soybean.

Results from a greenhouse trial in 2021 showed that, across 13 sample dates over a nearly 4-month period evaluating the effects of fertilizer-P source on greenhouse gas fluxes and emissions from flood-irrigated rice, CO2 fluxes were unaffected by fertilizer-P source, but differed over time, while both CH4 and N2O fluxes differed among fertilizer-P treatments over time. Furthermore, results showed generally lower CO2, CH4, and N2O fluxes from ECST than from the other fertilizer-P sources and numerically lower CO2 and N2O season-long emissions from ECST than from the other fertilizer-P sources, while CH4 emissions from ECST were numerically lower than from CPST in flood-irrigated rice. Electrochemically precipitated struvite may have potential to reduce greenhouse gas emissions from flood-irrigated rice.

Future Plans

Future plans include additional laboratory rainfall-runoff simulation experiments, greenhouse potted-plant trials, and field studies to evaluate the effects of real-wastewater-derived struvite compared to other commonly used, commercially available fertilizer-P sources on soil and plant response as well as greenhouse gas emissions.

Authors

Presenting author

Lauren F. Greenlee, Associate Professor, Pennsylvania State University

Corresponding author

Kristofor R. Brye, University Professor, University of Arkansas

Corresponding author email address

kbrye@uark.edu

Additional authors

Lauren F. Greenlee, Associate Professor, Pennsylvania State University

Niyi Omidire, Post-doctoral Research Associate, University of Arkansas

Tatum Simms, Graduate Research Assistant, University of Arkansas

Diego Della Lunga, Graduate Research Assistant, University of Arkansas

Ryder Anderson, former Graduate Research Assistant, University of Arkansas

Shane Ylagan, Graduate Research Assistant, University of Arkansas

Machaela Morrison, Graduate Research Assistant, University of Arkansas

Chandler Arel, Graduate Research Assistant, University of Arkansas

Additional Information

Anderson, R., K.R. Brye, L. Greenlee, and E. Gbur. 2020. Chemically precipitated struvite dissolution dynamics over time in various soil textures. Agricultural Sciences 11:567-591.

Ylagan, S.R., K.R. Brye, and L. Greenlee. 2020. Corn and soybean response to wastewater-recovered and other common phosphorus fertilizers. Agrosystems, Geosciences & Environment 3:e20086.

Anderson, R., K.R. Brye, L. Greenlee, T.L. Roberts, and E. Gbur. 2021. Wastewater-recovered struvite effects on total extractable phosphorus compared with other phosphorus sources. Agrosystems, Geosciences & Environment 4:e20154.

Anderson, R., K.R. Brye, L. Kekedy-Nagy, L. Greenlee, E. Gbur, and T.L. Roberts. 2021. Total extractable phosphorus in flooded soil as affected by struvite and other fertilizer-P sources. Soil Science Society of America Journal 85:1157–1173.

Anderson, R., K.R. Brye, L. Kekedy-Nagy, L. Greenlee, E. Gbur, and T.L. Roberts. 2021. Electrochemically precipitated struvite effects on extractable nutrients compared to other fertilizer-P sources. Agrosystems, Geosciences & Environment 4:e20183.

Omidire, N.S., K.R. Brye, T.L. Roberts, L. Kekedy-Nagy, L. Greenlee, E.E. Gbur, and L.A. Mozzoni. 2021. Evaluation of electrochemically precipitated struvite as a fertilizer-phosphorus source in flood-irrigated rice. Agronomy Journal 114:739–755. DOI: 10.1002/agj2.20917

Brye, K.R., and L.F. Greenlee. 2022. What is struvite and how is it used? Blog post for Soil Science Society of America’s “Soils Matter” blog (https://soilsmatter.wordpress.com/).

Acknowledgements

The authors acknowledge funding from the USDA NIFA AFRI Water for Food Production Systems program, grant #2018-68011-28691 and funding from the National Science Foundation, grant #1739473.

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2022. Title of presentation. Waste to Worth. Oregon, OH. April 18-22, 2022. URL of this page. Accessed on: today’s date.

A Decision-Support Tool for The Design and Evaluation of Manure Management and Nutrient Reuse in Dairy and Swine Farm Facilities

Purpose

The decision-support tool (DST) being developed facilitates the selection of manure treatment technology based on farm needs and nutrient balance requirements. A life cycle assessment (LCA) approach is used to determine and allocate among sources the whole-farm greenhouse gas (GHG) emissions and environmental impact of different manure management systems (MMS) to facilitate decision-making. The purpose of the tool is to help users identify the suite of technologies that could be used, given the farm’s unique set of preferences and constraints. The tool asks for an initial set of farm details and these values are cross-checked with predefined conditions before starting the simulation. This tool helps in the rapid quantification and assessment of treatment technology feasibility, GHG emissions, environmental, and economic impacts during the manure management decision-making process (Fig. 1). The decision algorithm operates based on user input for weightage priorities of criteria and sub-criteria related to environmental, economic, and technical components.

What Did We Do?

The DST is a Microsoft Excel-based tool with precalculated mass balance for a selected number of MMS alternatives representing current and emerging treatment technologies and practices. The MMS considered for the tool includes various handling systems, aerobic and anaerobic treatment systems, solid-liquid separation techniques, chemical processing units, etc. Modules were developed based on mass and energy balances, equipment capital & operating costs, unit process, and technology performance, respectively. The tool utilizes data specific to the country/region/farm where feasible and default values to calculate the overall economic and environmental performance of different MMS, providing results unitized per animal/day or per year.

Then, an LCA approach is used to evaluate the potential environmental footprints of each MMS considered. A life cycle impact assessment (LCIA) is comprised of detailed quantification of inputs and outputs of material flows in a specific treatment and/or conversion process. At the output level, it also defines and quantifies the main product, co-products, and emissions. The major focus on the treatment methods is quantifying the raw materials (manure, wash-water, bedding, etc.) that are to be handled in each MMS, thereby characterizing the properties of effluents (nutrients, gas emissions, etc.). The results include carbon, energy, water, land, nitrogen, and phosphorus footprints along with the effluent nitrogen, phosphorous, and potassium concentrations.

What Have We Learned?

Systematic selection of appropriate technology can provide environmental and economic benefits. Manure management systems vary in their design, due to individual farm settings, geography, and end-use applications of manure. However, the benefits of technological advancements in MMS provide manure management efficiencies and co-production of valuable products such as recycled water, fiber, sand bedding, and nutrient-rich bio-solids, among others. The handling efficiencies and environmental benefits provided by manure treatment technologies come with additional costs, however, so the tradeoffs between environmental benefits and implementation costs also need evaluation.

Future Plans

The next steps are to finalize the dairy module. We are refining the tool’s user interface and demonstrating to stakeholders to gather information regarding key assumptions, outputs, and the functionality of the tool. Further, we also plan to complete the swine module.

Authors

Sudharsan Varma Vempalli, Research Associate, University of Arkansas

Corresponding author email address

Additional authors

Sudharsan Varma Vempalli, Research Associate, University of Arkansas

Erin Scott, PhD Graduate Assistant, University of Arkansas

Jacob Allen Hickman, Project Staff, University of Arkansas

Timothy Canter, Extension Specialist, University of Missouri

Richard Stowell, Professor, University of Nebraska-Lincoln

Teng-Teeh Lim, Extension Professor, University of Missouri

Lauren Greenlee, Associate Professor, The Pennsylvania State University

Jennie Popp, Professor, University of Arkansas

Greg Thoma, Professor, University of Arkansas

Additional Information

Detailed economic impacts and tradeoffs expected with the implementation of certain MMS related to this tool is presented during the conference by Erin Scott et al., on the topic “Evaluating Costs and Benefits of Manure Management Systems for a Decision-Support Tool”.

Varma, V.S., Parajuli, R., Scott, E., Canter, T., Lim, T.T., Popp, J. and Thoma, G., 2021. Dairy and swine manure management–Challenges and perspectives for sustainable treatment technology. Science of The Total Environment, 778, p.146319. https://www.sciencedirect.com/science/article/pii/S0048969721013875

Acknowledgements

We acknowledge funding support from the United States Department of Agriculture (USDA) National Institute of Food and Agriculture (NIFA) grant award (# 2018-68011-28691). We would also like to thank our full project team and outside experts for their guidance on this project.

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2022. Title of presentation. Waste to Worth. Oregon, OH. April 18-22, 2022. URL of this page. Accessed on: today’s date.

Evaluating Costs and Benefits of Manure Management Systems for a Decision-Support Tool

Purpose

The purpose of the decision-support tool is to help livestock producers understand the costs of implementing new technology and the potential benefits associated with nutrient and water recovery, and how these compare across systems. Livestock agriculture is under increased scrutiny to better manage manure and mitigate negative impacts on the environment. At the same time, the nutrients and water present in manure management systems hold potential economic value as crop fertilizer and irrigation water. While technologies are available that allow for recovery and/or recycling of solids, nutrients and water, appropriate decision-support tools are needed to help farmers evaluate the practicality, costs, and benefits of implementing these systems on their unique farms.

What Did We Do?

In designing and refining the tool, we consider which economic components are important in driving the decision algorithm, as well as what is the most valuable economic output information for the user. We developed several “scenarios” defined by the unit processes used in the capture, treatment, storage, and usage of dairy manure. The costs and benefits related to each unit process were evaluated and aggregated for each scenario. Unit processes included flush/scrape activities, reception pit, sand recovery, solids separation, anaerobic digestion, composting, pond/lagoon storage, and tanker/drag hose land application.

Economic information was gathered from published literature, government documents, extension tools, and communication with academic, industry, and extension experts. We evaluated capital costs as an annual capital recovery value; operational costs including labor, energy, and repair and maintenance; cost savings resulting from sand/organic bedding and water reuse; fertilizer value of manure for use on-farm; revenue potential including the sale of treated manure nutrients and energy from anaerobic digestion; and the combined net costs or net benefits. Economic results are integrated into the multi-criteria decision algorithm. Results also elucidate economic tradeoffs across manure management systems (MMS), which can be used by farmers to assist in their decision-making.

What Have We Learned?

Economics is often about evaluating trade-offs between different choices or decisions. When evaluating results from the tool, we see that an increase in capital spending may lead to decreases in operational costs relative to capital costs, depending on farm size. This is due to a general reduction in labor and fuel costs associated with automated or additional manure treatment (e.g. increased spending on an MMS). For example, additional manure treatment can reduce land application expenses and increase cost savings from recovered sand or organic bedding. However, this larger capital outlay may or may not be possible based on the farm’s financial circumstances.

Future Plans

The next steps are to complete the economic analyses of a total of 60 MMS and integrate these into the decision-support tool. We plan to demonstrate this tool to extension specialists and producers to refine the user interface, key assumptions, functioning of the decision algorithm, and the usability of the results.

Authors

Erin E. Scott, PhD Graduate Assistant, University of Arkansas

Corresponding author email address

Additional authors

Sudharsan Varma Vempalli, Postdoctoral Research Associate, University of Arkansas

Jacob Hickman, Program Coordinator, University of Arkansas

Jennie Popp, Professor, University of Arkansas

Richard Stowell, Professor, University of Nebraska-Lincoln

Teng Lim, Extension Professor, University of Missouri

Greg Thoma, Professor, University of Arkansas

Lauren Greenlee, Associate Professor, Penn State University

Additional Information

Related presentation during this session by Varma et al., titled “A Decision-Support Tool for The Design and Evaluation of Manure Management and Nutrient Reuse in Dairy and Swine Farm Facilities”.

Acknowledgements

We acknowledge funding support from the United States Department of Agriculture (USDA) National Institute of Food and Agriculture (NIFA) grant award (# 2018-68011-28691). We would also like to thank our full project team and outside experts for their guidance on this project.

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2022. Title of presentation. Waste to Worth. Oregon, OH. April 18-22, 2022. URL of this page. Accessed on: today’s date.

Advances in Nutrient Recovery Technology: Approaches to Controlling Recovered Product Chemistry

Purpose

Our recent work has focused on developing approaches to nutrient management and recovery, with a particular focus on using electrochemical and membrane technologies to control the chemistry of the recovered nutrient products. We are interested in being able to recover both ammonia and phosphate, and our goal is to create recycled fertilizer products that can allow the agricultural community to control the ratio of nitrogen to phosphorus in the recycled fertilizer products and to control whether those fertilizer products are in liquid form or in solid form. With the electrochemical technology focus, we see benefits that include no required chemical dosing, scalable reactor design, and the ability to couple to renewable energy sources. Our engineering research on nutrient recovery technology is conducted within a team that includes life cycle assessment, economic analysis, agronomic greenhouse and row crop studies, agricultural sector outreach, and the development of a decision-support tool to help farmers understand technology options for water and nutrient management.

What Did We Do?

We have investigated an electrochemical cell design that includes a magnesium metal anode and a stainless-steel cathode. The corrosion of the magnesium anode results in the release of magnesium cations into solution, and these magnesium cations promote the precipitation of struvite, otherwise known as magnesium ammonium phosphate hexahydrate (Figure 1). We have investigated how operating conditions of the electrochemical cell, including voltage, residence time, batch vs flow, and membrane separation of the two electrodes, affect nutrient recovery efficiency and the overall chemistry of the recovered precipitate. Our studies have included control experiments on synthetic wastewater compositions relevant to hog and dairy farm wastewaters, while we have also conducted laboratory-scale studies on natural wastewater samples from both agricultural and municipal sources. To demonstrate initial scale-up of an electrochemical reactor, we have designed a bench-scale reactor (Figure 2) that is capable of producing kilogram-level batches of struvite.

What Have We Learned?

The production of struvite from an electrochemical reactor can be controlled by the applied voltage and residence time of the wastewater in the reactor. Changes in reactor design, including the inclusion of a membrane to separate the anode and cathode and operation in batch vs flow mode, can change the composition of the struvite precipitate and can cause a change in the balance of struvite formed vs hydrogen gas formed from the electrochemical cell. We are also able to produce K-struvite, a potassium-based alternative to conventional struvite, that includes potassium rather than ammonium, and the production of K-struvite allows the recovery of the phosphate in a particulate fertilizer while also allowing the separation and recovery of ammonia in a separate liquid stream. We have learned that one of the primary challenges to the electrochemical reactor operation is fouling of the electrodes by the struvite precipitate (Figure 2), and we have developed a dynamic voltage control approach that enables minimal electrode fouling and therefore increases struvite recovery and decreases energy consumption. Our energy consumption values are similar to that of chemical precipitation processes that have been developed for nutrient recovery.

Future Plans

Future plans include further development and optimization of the dynamic voltage control approach to electrochemical reactor operation, which will allow us to control electrode fouling. We also plan to continue working with natural wastewater samples and further develop flow cell reactor design to understand how to translate our batch reactor studies to a flow reactor environment. Studies on K-struvite will focus on understanding the kinetics of K-struvite precipitation and the competing reactions (e.g., calcium precipitation and struvite precipitation) that might impact K-struvite recovery.

Authors

Lauren F. Greenlee, Associate Professor, Pennsylvania State University

Corresponding author email address

greenlee@psu.edu

Additional authors

Laszlo Kekedy-Nagy, Postdoctoral Fellow, Concordia University

Ruhi Sultana, Graduate Research Assistant, Pennsylvania State University

Amir Akbari, Graduate Research Assistant, Pennsylvania State University

Ivy Wu, Graduate Research Assistant, Colorado School of Mines

Andrew Herring, Professor, Colorado School of Mines

Additional Information

-

- Kekedy-Nagy, Z. Anari, M. Abolhassani, B.G. Pollet, L.F. Greenlee. Electrochemical Nutrient Removal from Natural Wastewater Sources and its Impact on Water Quality. Water Research (2022), 210, 118001, DOI: 10.1016/j.watres.2021.118001.

- Kékedy-Nagy, M. Abolhassani, R. Sultana, Z. Anari, K.R. Brye, B.G. Pollet, L. F. Greenlee. The Effect of Anode Degradation on Energy Demand and Production Efficiency of Electrochemically Precipitated Struvite, Journal of Applied Electrochemistry (2021), DOI: 0.1007/s10800-021-01637-y.

- Kékedy-Nagy, M. Abolhassani, S.I. Perez Bakovic, J.P. Moore II, B.G. Pollet, L.F. Greenlee. Electroless Production of Fertilizer (Struvite) and Hydrogen from Synthetic Agricultural Wastewaters, Journal of the American Chemical Society (2020), 142(44), 18844-18858. DOI: /10.1021/jacs.0c07916.

- Wu, A. Teymouri, R. Park, L.F. Greenlee, and A.M. Herring. Simultaneous Electrochemical Nutrient Recovery and Hydrogen Generation from Model Wastewater Using a Sacrificial Magnesium Anode, Journal of the Electrochemical Society (2019), 166(16), E576-E583. DOI: 10.1149/2.0561916jes.

Acknowledgements

The authors acknowledge funding from the USDA NIFA AFRI Water for Food Production Systems program, grant #2018-68011-28691 and funding from the National Science Foundation, grant #1739473.

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2022. Title of presentation. Waste to Worth. Oregon, OH. April 18-22, 2022. URL of this page. Accessed on: today’s date.

Manure Treatment Technology Adoption by Swine and Dairy Producers: Survey Feedback

Purpose

Sound management of manure is essential to optimize its benefits for soil health and crop production, and to minimize costs and environmental risks. Along with changes in farm scale and practices, modern farms are increasingly looking to process or treat manure to address problem areas and to take advantage of market opportunities on their operations. A variety of manure treatment technologies are available and new technologies continue to be developed for managing nutrients, solids, energy, water, and other components of manure. But, while these new treatment technologies hold potential to improve the environmental, economic, and social sustainability of livestock and poultry production, questions remain regarding producer adoption of treatment systems on their operations. To improve our understanding of decision-making processes employed when producers evaluate and adopt manure treatment technologies, the authors conducted a survey aimed at dairy and swine producers in the Midwest.

What did we do?

Two surveys were developed, one tailored to dairy producers and one for swine producers. All operation sizes and production systems were included. The surveys were administered using Qualtrics, an online survey platform. Questions asked covered manure-related practices in animal facilities, manure handling, and land application. Additional questions asked producers to prioritize their needs for manure treatment, factors influencing technology selection, current technologies being utilized, and principal barriers for adoption. Respondents were asked to select up to three critical outcomes for their farms’ manure treatment technologies, the most influential factors (or technology characteristics) for manure treatment adoption, and the main barriers for technology adoption. The authors collaborated with Nebraska Extension and with state producer associations to reach swine and dairy producers in Nebraska and other Midwest states, with the survey first launched in the fall of 2021. Magazine articles, radio programs, listservs, and social media were used to promote the surveys.

Responses were analyzed using descriptive methods. Eighteen respondents provided information to characterize seven swine farms and ten dairy operations. Swine respondents had farms in Nebraska (7), Iowa (2), and Ohio (1). For dairy, 7 of the farms were in Nebraska and 1 was in Minnesota. Swine farm systems were divided between the ones that had farrowing (farrow-to-finish and farrow-to-wean systems) and the ones without it (grow-to-finish and wean-to-finish systems) (Table 1). Respondents were asked to provide insights for their farms’ primary manure management systems. A dairy operation’s primary manure management system was defined as the one receiving manure from the lactating cows. For swine, the primary manure management system received manure from the gestation sows or the finishing herd. For both swine and dairy, secondary systems were defined as utilizing separate storage and handling facilities.

| Species and herd type | Number of farms | Herd size – average | Herd size – range |

|---|---|---|---|

| Dairy – lactating cow herd | 8 | 933 | 30 to 2,150 |

| Swine (farrowing) – sow herd | 4 | 2,762 | 250 to 7,500 |

| Swine (finishing) – finisher herd | 5* | 23,600 | 1,200 to 70,000 |

| Note: *One finishing farm did not share its herd size information. | |||

What have we learned?

The dairy and swine farms demonstrated differences in manure treatment needs and consequently adopted different treatment technologies (Figures 1 and 2).

FTF = farrow-to-finish

PSOP = partially slotted open pens

PP = pull-plugs

FTW = farrow-to-wean

ISWPSF = individual stalls w/partial slotted floor

DP = deep pits

GF-F = grow-finish or finishing

ASFB = all slotted-floor building

FL = flushing

WTF = wean-to-finish

CH = chemicals

AE = aeration

LA = lagoons

AD = anaerobic digestion

CO = composting

CS = corn stalks

Sd = sedimentation

DD = direct drying

Mch = mechanical

TL = treatment lagoon

Co = composting

Stt = sand settling lane or basin

AE = aeration

NS = no separation

AD = anaerobic digestion

The most-used technologies in the primary manure management system for each industry were: mechanical separation, sand settling lanes, and sedimentation basins for dairy farms; and addition of chemicals, treatment lagoons, and composting for swine operations (Figure 3).

Allowing water to be reused and exporting nutrients were the primary desired outcomes of implementing manure treatment technologies for dairy and swine farms, respectively (Figure 4). Accordingly, 6 of 7 dairy farms were recycling water in their operations, while only 1 out of 10 was doing so on the swine side.

Diverse factors influenced the selection of the implemented technologies in both livestock operations. Low management demand, low maintenance, “performs best functionally” (best performance achieving the desired goals of manure treatment), and low initial cost are among the most-mentioned factors (Figure 5).

Swine and dairy farmers identified initial cost, operational cost, and return on investment as the primary barriers to future technology adoption (Figure 6). Management demand was another important barrier among swine producers.

None of the survey respondents used membranes, electrochemical precipitation, or gasification technologies, demonstrating that cutting-edge manure treatment technologies are being more slowly adopted by regional livestock producers. The high cost and potential high management demand of these technologies could be barriers for their adoption.

Future plans

Our research work has moved into qualitative exploration. Focus groups will be held with swine and dairy producers, where they will discuss and share their manure treatment needs and desired outcomes from new treatment options. These activities will be organized online and will allow producers to share their manure management perspectives for the present and future. The results of our surveys and focus groups are being used to inform a decision-support tool being developed as part of the Management of Nutrients for Reuse (MaNuRe) project. Our findings will also be used to help develop extension programs that meet the needs of producers for manure management in Nebraska and neighboring states.

Authors

Juan Carlos Ramos Tanchez, Graduate Research Assistant, University of Nebraska-Lincoln.

Corresponding author email address

jramostanchez2@huskers.unl.edu

Additional authors

Richard Stowell, Professor of Biological Systems Engineering, University of Nebraska-Lincoln.

Amy Schmidt, Associate Professor of Biological Systems Engineering, University of Nebraska-Lincoln.

Acknowledgements

Funding for this effort came from the USDA NIFA AFRI Water for Food Production Systems program, grant #2018-68011-28691. The authors would like to express gratitude to Dr. Teng Lim and Timothy Canter (University of Missouri), Mara Zelt, and Lindsey Witt-Swanson (University of Nebraska-Lincoln) for their relevant support to this study. We would also like to thank the staff at the Nebraska Pork Producers Association and the Nebraska State Dairy Association for their collaboration on our research.