The final in a series of 3 webinars, this presentation focuses on producer perspectives of carbon markets for livestock operations. This presentation originally broadcast on January 20, 2023. Continue reading “Carbon Markets for Livestock Operations: Producer Perspectives”

Inclusion of the Environment Bottom Line in Waste to Worth: The Interaction Between Economics, Environmental effects, and Farm Productivity in Assessment of Manure Management Technology and Policy

Proceedings Home | W2W Home

Purpose

In a global context, the pork industry constitutes a huge economic sector but many producers operate on very thin margins. In addition, pork is one of the largest and most important agricultural industries in North Carolina and the United States but faces a number of challenges in regards to waste management and environmental impacts.On more local scales, swine producers face a number of additional constraints including land availability, waste management options (technical and regulatory), nutrient management costs, profits, risk, and return on investment. In the face of increasingly stringent environmental regulations, decreasing land availability, and higher costs for fertilizer, it is necessary to consider alternative technologies with the potential for improving environmental conditions and creating value added products. Technology assessments generally focus on technical performance as the measure of “utility” or usefulness. Primary physical performance measures such as efficiency, production rate, and capacity, while necessary may not be sufficient for capturing the overall value of a technology. A significant amount of research has evaluated the feasibility of technology adoption based on traditional economic measures but far less research has attempted to “value” environmental performance either at farm-scale or in the larger context (e.g. supply chain response to changes in technology or policy and regulation). Considering response over time, the extent to which environmental and economic policies and regulations positively or negatively affect technology innovation, emission and nutrient management, competitiveness, and productivity, remains largely unknown.

The purpose of this study is to evaluate the environmental and economic tradeoffs between current swine waste management practices in North Carolina and alternative scenarios for future on-farm decision making that include new technologies for waste removal, treatment, and nitrogen recovery. In addition, we begin to understand these economic and environmental tradeoffs in the context of various environmental policy and regulation scenarios for markets of carbon, electricity, and mineral fertilizer.

What did we do?

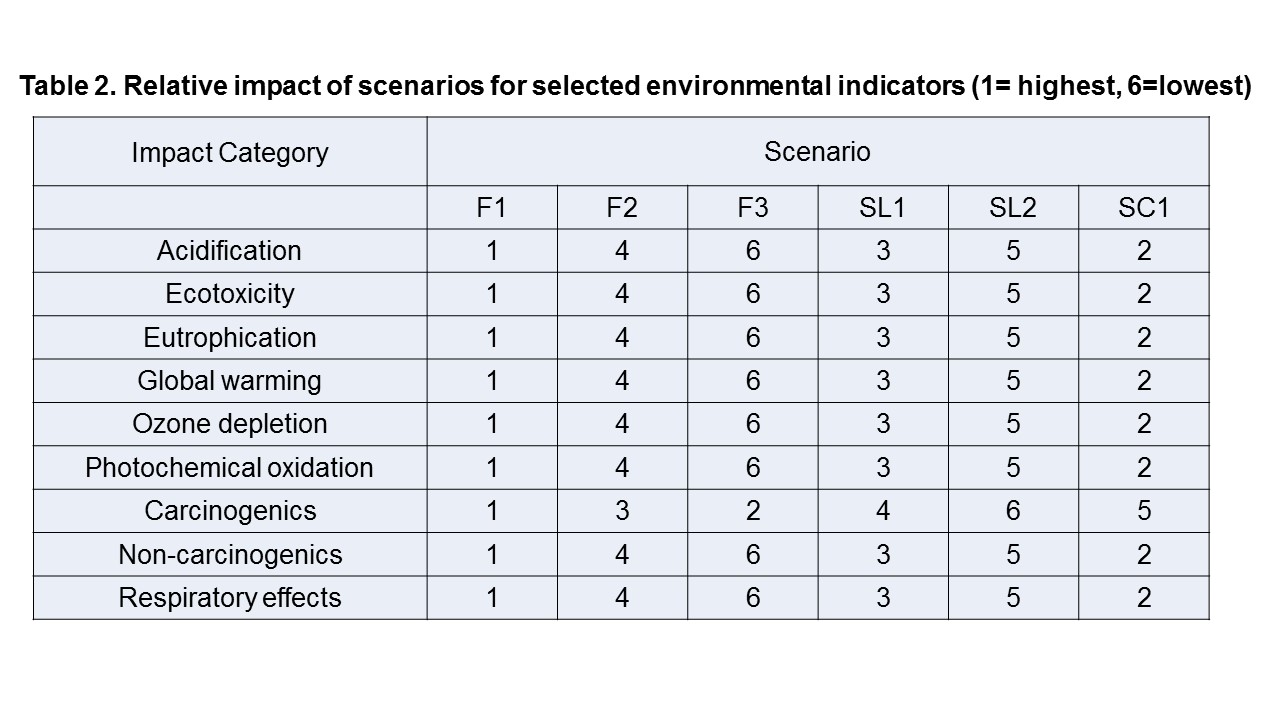

Using waste samples from swine finishing farms in southeastern NC, laboratory and bench scale experiments were conducted to determine the quantity and quality of biogas generation from anaerobic digestion and nitrogen recovery from an ammonia air stripping column. Based on these data as well as information from literature, six trial life cycle assessment scenarios were created to simulate alternatives for annual manure waste management for one finishing barn (3080 head) on the farm. Materials, energy, and emissions were included as available for all system components and processes including but not limited to waste removal from barns (flushing or scraping), treatment (open air lagoon or covered lagoon digester), nitrogen recovery (ammonia air stripping column), and land application (irrigation). A description of the scenarios as well as processes that are included/excluded for each can be found in Table 1. All scenarios were modeled over a one year operational period using a “gate to gate” approach where the mass and energy balance begins and ends on the farm (i.e. production of feed is not included and manure is fully utilized on the farm). It was assumed that each scenario included an existing anaerobic treatment lagoon with manure flushing system (baseline, representative of NC swine farms). In the remaining scenarios, the farm had an option of covering the lagoon and using it as a digester to produce biogas (offsetting natural gas); covering the digester and ammonia air stripping column for nitrogen recovery (offsetting mineral ammonium sulfate); installing a mechanical scraper system in the barn (replaces flushing); and/or different combinations of these. Open LCA, an open source life cycle and sustainability assessment software, was used for inventory analysis and the Tool for Reduction and Assessment of Chemicals and Other Environmental Impacts (TRACI 2.0) was used to characterize environmental impacts to air, water, and land. From Table 2 preliminary results indicate that all scenarios had a similar pattern in terms of impact for the assessed categories. The open air lagoon had the highest overall environmental impact followed by scraping manure with digestion and recovery and scraped slurry digestion with no nutrient recovery. Flushed manure to the digester with nutrient recovery had the lowest overall environmental impact, followed closely by scraped whole slurry to the digester with nutrient recovery.

Using energy and emissions data from the initial life cycle assessment on alternative scenarios for swine waste management systems we have started to characterize the environmental and economic outcomes arising from selected on farm technologies. More specifically we began to examine the regulatory, institutional, and market barriers associated with technology adoption within the swine industry. We provide a theoretical model to support quantification of the change in revenues and expenses that result from changes in three major markets connected to swine production – carbon, electricity, and fertilizer. We examine some of the economic characteristics of environmental benefits associated with changes to farm practices. Finally, we discuss implications for innovation in technology and policy.

What have we learned?

Preliminary results are somewhat mixed and further research is needed to see how sensitive the life cycle assessment inputs and outputs are to system components. While there is a clear indication that covering lagoons, with or without additional nutrient recovery, reduces environmental impact – farm scale systems can be quite expensive and no further determination can be made until a full economic analysis has been conducted. Modeling secondary effects, such as increased ammonia emissions in barns from flush water recirculated from digesters, remains to be included. Besides farm level cost and returns, review of literature has pointed to additional barriers to adoption of reduced environmental impact technologies. Examples of barriers include deficient or non-existent markets for environmental benefits, and various state and federal regulations and policies related to renewable energy, carbon offsets, new farm waste management technology, etc. Solutions such as better cooperation between energy firms, regulatory agencies, and farmers as well as increased financial incentives such as carbon credits, renewable energy credits, net metering options, and enabling delivery of biogas to natural gas pipelines can greatly increase the profitability and implementation of this technology on NC hog farms.

Future Plans

As this is an ongoing multi-disciplinary project, future plans include the expansion of existing data to form a more comprehensive life cycle inventory with options for both new and existing swine farms, which include additional options for waste treatment, nutrient recovery, and land application/fertilizer methods, etc. Energy and emissions data from the life cycle model will continue to be utilized as inputs into a more fully integrated model capable of reflecting the true “cost” and “values” associated with waste management treatment systems. In addition, it is expected that the integrated model will include the flexibility to simulate overall costs and returns for various sizes of operations within the county, region, and if possible state-wide.

Corresponding author, title, and affiliation

Shannon Banner, Graduate Student, North Carolina State University

Corresponding author email

Other authors

Dr. John Classen, Dr. Prince Dugba, Mr. Mark Rice, Dr. Kelly Zering

Acknowledgements

Funding for this project was provided by a grant from Smithfield Swine Production Group

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2017. Title of presentation. Waste to Worth: Spreading Science and Solutions. Cary, NC. April 18-21, 2017. URL of this page. Accessed on: today’s date.

Anaerobic Digestion – Highlights of Successful Project Feasibility Studies

Purpose

Feasibility studies are a form of decision-making tool that require research, data collection and analysis to evaluate investments in new technology or projects. They answer key questions about a project’s technical and financial viability, including project structure and organization and the costs, benefits, and risks involved. The analyses completed are so important that many grant programs require feasibility studies before making project grant awards. Financial investors and banks commonly may require the most rigorous form of feasibility study prior to making any investment.

What did we do?

To develop a catalog of steps needed to perform a successful feasibility study, we reviewed the literature on feasibility studies, as well as dozens of studies done on the subject of anaerobic digestion. We also talked with a range of experts in project development.

What have we learned?

General Assessment Study or Screening—Most basic feasibility studies assess the viability of different opportunities within a defined industry or geographic area. On a project level, a general assessment determines if a potential project meets basic criteria thresholds to support more in-depth analysis?

Project-Based, Techno-Economic Study—A higher level of research and analysis is used to establish project viability. These studies consider the costs, benefits, and risks of building a specific type of project, with specific technology, on a specific site. For this purpose the study might incorporate readily available data about technology choices and make assumed adjustments about how it would perform under site-specific conditions. This level of analysis forces project advocates to put their ideas and assumptions on paper and test whether the conclusion is sound and realistic.

Investment-Grade Study—The most rigorous feasibility study is used to validate the marketability of a specific project from an investment perspective. It would look beyond basic techno-economic viability to establish the actual planned inputs and outputs of a project. It can include detailed equipment specifications and estimates, as well as detailed mass, energy, and water balance calculations. It may also identify key providers of feedstocks as well as potential end users. Detailed scheduling may be required to complete financial analyses accurately. With a detailed proforma showing financial analyses of cash flow and return on investment, this high level of feasibility study is sometimes termed “investment-grade.” These types of studies often include sensitivity analyses to explore the impact on a project’s viability from changes to one or more key assumptions. Sensitivity analyses can clarify which of the many assumptions made are most critical to project success.

Getting the best, most reliable and accurate data is perhaps the most critical element of a successful feasibility study. Typical steps observed in many feasibility studies:

- Define project goals and scope

- Establish the project criteria necessary for success

- Inputs: potential feedstocks from measured results, existing data, or surveys of sources

- Outputs, calculated from inputs: biogas, liquid and solid effluents and nutrients, and environmental attributes

- Financial costs: capital expenses, including cost of money, and ongoing operation and maintenance expenses

- Revenues (10 or more): methane energy power or fuel, surplus thermal energy, tip fees, value of solids, liquids-water, liquids-nutrients, environmental attributes, ecosystem services (e.g., GHG offsets, water quality/quantity benefits), carbon dioxide, and/or bioplastics.

- Cost offsets as revenues: e.g., rainwater diversion, reduction in manure handling/spreading, odor reduction, avoided disposal, etc.

- Financial analyses: cash flow, simple payback, EBITA (earnings before interest, taxes and amortization), net present value, return on investment, sensitivity analyses, life-cycle analyses

- Project finance: grants and loan guarantees, debt, and equity

- Project ownership and liabilities: including design, build, own, operate, maintain

Future Plans

We will continue to evaluate methods to add value and publish the full results in a Anaerobic Digestion technology brief on this topic.

Authors

Jim Jensen, Sr Bioenergy & Alt Fuel Specialist, Washington State University Energy Program jensenj@energy.wsu.edu

Craig Frear, Chad Kruger, and Georgine Yorgey, Center for Sustaining Agriculture and Natural Resources, Washington State University

Additional information

Acknowledgements

This research was supported by Biomass Research Funds from the WSU Agricultural Research Center; and by the Washington State Department of Commerce.

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2015. Title of presentation. Waste to Worth: Spreading Science and Solutions. Seattle, WA. March 31-April 3, 2015. URL of this page. Accessed on: today’s date.

Digested Solids – Forms, Markets and Trends

Are Digested Solids a Viable Product?

Anaerobic digesters for U.S. livestock operations are becoming more complex. A study of livestock-based digesters in 2003 found they were built largely to meet on-farm needs for power or gas. Digester residuals were mostly land applied as nutrients for crop production. A few used fibrous solids as animal bedding (King, 2003). In recent years, more livestock-based digester projects have been built by third-party developer/managers. Projects increasingly employ a systems approach, where individual product streams are managed in concert for greatest profit by the project manager. This approach holds the promise that digestate residuals, especially fiber solids, will no longer be neglected, but instead play a larger role in offsetting weak performance in energy revenues.

What did we do?

Looking closely at dairy-based digesters, the solids recovered after separation from the digester eflluent have unique characteristics. Most notably, these solids tend to be fibrous with high cellulose, hemicellulose, and lignin content. Digestion also reduces pathogenic contaminants, volatile solids, odor, and viable weed seeds (MacConnell, 2010). These qualities can be influenced by the makeup of an animal’s feed and the use of co-digestion feedstocks, such as municipal or industrial wastes or other agricultural manures or byproducts

Table 1 shows the characteristics of dairy AD solids compared to raw manure and raw separated solids (MacConnell, 2010).

As is. In bulk. Sold to a wholesale buyer—this is the easiest way to sell digested dairy fiber. Through a combination of literature search and expert interviews, this presentation looks at the methods project managers might use to add more value to their digested fiber.

What have we learned?

Composting. Perhaps the most basic way to add value to digested dairy fiber is simply to apply basic compost processing methods—aerating the material under controlled conditions for sufficient time to reduce odor and stabilize the organic matter. While already low in pathogens, hot composting practices can give additional assurance of pathogen reduction. In co-digestion situations, screening the material to remove contaminants and assure consistency and uniformity is desired. Even wholesale buyers will pay more for material that is already composted (King 2003)

Processing to compete – replacing peat. Because of its physical similarity, researchers have explored using digested dairy fiber as a direct replacement for peat moss in nursery and horticulture mixes. WSU was an early source of research and growth trials on such uses. Their research showed that with minimal post-digestion treatment, amended digested dairy fiber performed as well or better than peat in soilless mixes. (MacConnell, 2007, and Kruger, 2008) In 2007, Organix, a Washington company, announced the first shipments of RePeat, using their patent-pending FibreRite production system. Since then several new varieties of these peat replacements have hit the market nationwide, under such brands as Magic Dirt, EnerGro, and MooFiber.

Organic certification. Organic gardening and food production is growing rapidly in Washington state and around the nation. Getting an organic certification for organic matter and nutrients that have been digested and composted will add significant value to the final product (King, 2003).

Branding and marketing for retail. Moving away from bulk and wholesale are the next steps in moving material up the value chain. However, putting product in bags and selling into retail markets requires significant investments in packaging, branding, marketing and sales. This is like adding an additional business onto the back end of a digester project and demands its own feasibility analysis.

Vermicomposting. Using earthworms, especially redworms, to further process fiber solids and excrete earthworm castings, produces another specialty soil product. Vermicomposts and earthworm castings are well-known and appreciated in some growers in some markets. They are often used as a small additive in specialty soil mixes to allow the use of “earthworm castings” on the list of ingredients. Two commercial examples of vermicompost production lie on opposite coasts—Sonoma Valley Worm Farm in California and Worm Power in New York. Sonoma Valley Worm Farm direct markets high-quality vermicompost to a variety of growers throughout their region, with special emphasis on vineyards. Worm Power topped 2 million pounds of production in 2012 and signed an agreement with Rochester, NY-based Harris Seeds to market its vermicompost products regionally.

Specialty products produced from the separated fiber materials are another area of interest. Perhaps the best known of such products are the biodegradable planting nursery pots sold as Cow Pots by the Fruend Dairy Farm in Connecticut.

Biochar. This is another specialty product from a fledgling industry that fits in niche markets. It could be used to process digested fiber. It has received a strong research focus in the Pacific Northwest. The value of biochar in landscape or agricultural uses is still being studied, though at present it appears to have less to do with agronomic benefit, than on measured benefits for carbon sequestration and the value given to these benefits through carbon credits or other mechanisms (Galinato, 2011). On the other hand, replacing biochar for conventional forms of activated carbon for filtering stormwater or wastewaters shows some promising results and is getting a lot of attention.

Future Plans

We will continue to evaluate methods to add value and publish the full results in a Anaerobic Digestion technology brief on this topic.

Authors

Jim Jensen, Sr. Bioenergy & Alt Fuel Specialist, Washington State University Energy Program jensenj@energy.wsu.edu

Craig Frear, Chad Kruger, and Georgine Yorgey, Center for Sustaining Agriculture and Natural Resources, Washington State University

Additional information

References:

Galinato, S., Yoder, J., Granatstein, D., 2011. The economic value of biochar in crop production. Energy Policy.

King, 2003. Study to Evaluate the Price and Markets for Residual Solids from a Dairy Cow Manure Anaerobic Digester—Final Report, King County Solid Waste, Seattle, WA.

Kruger, Chad, et.al., 2008. High-quality fiber and fertilizer as co-products from anaerobic digestion. Journal of Soil and Water Conservation.

MacConnell, C.B., Collins, H.P., 2007. Utilization of re-processed anaerobically digested fiber from dairy manure as a container media substrate. Proceedings of the International Symposium on Growing Media, Nottingham, UK.

MacConnell, C., Frear, C., Liao W., 2010. Pretreatment of AD-treated fibrous solids for value-added container media market, Center for Sustaining Agriculture and Natural Resources, Pullman, WA.

Acknowledgements

This research was supported by funding from USDA National Institute of Food and Agriculture, Contract #2012-6800219814; Biomass Research Funds from the Washington State University Agricultural Research Center; and the Washington State Department of Ecology, Waste 2 Resources Program.

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2015. Title of presentation. Waste to Worth: Spreading Science and Solutions. Seattle, WA. March 31-April 3, 2015. URL of this page. Accessed on: today’s date.