Purpose

The purpose of the decision-support tool is to help livestock producers understand the costs of implementing new technology and the potential benefits associated with nutrient and water recovery, and how these compare across systems. Livestock agriculture is under increased scrutiny to better manage manure and mitigate negative impacts on the environment. At the same time, the nutrients and water present in manure management systems hold potential economic value as crop fertilizer and irrigation water. While technologies are available that allow for recovery and/or recycling of solids, nutrients and water, appropriate decision-support tools are needed to help farmers evaluate the practicality, costs, and benefits of implementing these systems on their unique farms.

What Did We Do?

In designing and refining the tool, we consider which economic components are important in driving the decision algorithm, as well as what is the most valuable economic output information for the user. We developed several “scenarios” defined by the unit processes used in the capture, treatment, storage, and usage of dairy manure. The costs and benefits related to each unit process were evaluated and aggregated for each scenario. Unit processes included flush/scrape activities, reception pit, sand recovery, solids separation, anaerobic digestion, composting, pond/lagoon storage, and tanker/drag hose land application.

Economic information was gathered from published literature, government documents, extension tools, and communication with academic, industry, and extension experts. We evaluated capital costs as an annual capital recovery value; operational costs including labor, energy, and repair and maintenance; cost savings resulting from sand/organic bedding and water reuse; fertilizer value of manure for use on-farm; revenue potential including the sale of treated manure nutrients and energy from anaerobic digestion; and the combined net costs or net benefits. Economic results are integrated into the multi-criteria decision algorithm. Results also elucidate economic tradeoffs across manure management systems (MMS), which can be used by farmers to assist in their decision-making.

What Have We Learned?

Economics is often about evaluating trade-offs between different choices or decisions. When evaluating results from the tool, we see that an increase in capital spending may lead to decreases in operational costs relative to capital costs, depending on farm size. This is due to a general reduction in labor and fuel costs associated with automated or additional manure treatment (e.g. increased spending on an MMS). For example, additional manure treatment can reduce land application expenses and increase cost savings from recovered sand or organic bedding. However, this larger capital outlay may or may not be possible based on the farm’s financial circumstances.

Future Plans

The next steps are to complete the economic analyses of a total of 60 MMS and integrate these into the decision-support tool. We plan to demonstrate this tool to extension specialists and producers to refine the user interface, key assumptions, functioning of the decision algorithm, and the usability of the results.

Authors

Erin E. Scott, PhD Graduate Assistant, University of Arkansas

Corresponding author email address

Additional authors

Sudharsan Varma Vempalli, Postdoctoral Research Associate, University of Arkansas

Jacob Hickman, Program Coordinator, University of Arkansas

Jennie Popp, Professor, University of Arkansas

Richard Stowell, Professor, University of Nebraska-Lincoln

Teng Lim, Extension Professor, University of Missouri

Greg Thoma, Professor, University of Arkansas

Lauren Greenlee, Associate Professor, Penn State University

Additional Information

Related presentation during this session by Varma et al., titled “A Decision-Support Tool for The Design and Evaluation of Manure Management and Nutrient Reuse in Dairy and Swine Farm Facilities”.

Acknowledgements

We acknowledge funding support from the United States Department of Agriculture (USDA) National Institute of Food and Agriculture (NIFA) grant award (# 2018-68011-28691). We would also like to thank our full project team and outside experts for their guidance on this project.

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2022. Title of presentation. Waste to Worth. Oregon, OH. April 18-22, 2022. URL of this page. Accessed on: today’s date.

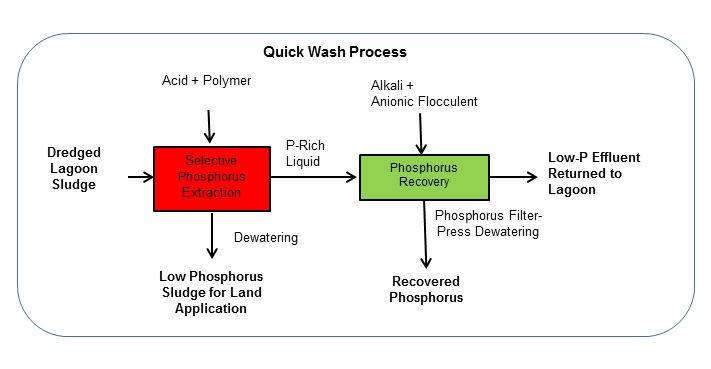

P was extracted in solution from dredged sludge by mixing with sulfuric acid prior to dewatering using polymer enhanced mechanical solid-liquid separation. After that, P was recovered by addition of liquid lime and an anionic flocculent to the separated liquid extract to form a calcium-containing P precipitate. The QW process generated two solid products: 1) sludge solids low in P; and 2) a concentrated P material.

P was extracted in solution from dredged sludge by mixing with sulfuric acid prior to dewatering using polymer enhanced mechanical solid-liquid separation. After that, P was recovered by addition of liquid lime and an anionic flocculent to the separated liquid extract to form a calcium-containing P precipitate. The QW process generated two solid products: 1) sludge solids low in P; and 2) a concentrated P material.