Several renewable natural gas (RNG) projects are either recently completed or on the books as potential new projects. With such a new business model, Washington State University, in concert with State officials embarked on a feasibility study to investigate costs/revenues as well as project consideration, hurdles and options for production of RNG as compared to an industry standard combined heat and power (CHP) model. The feasibility study was for an existing dairy anaerobic digestion project located near the Yakima Valley of Washington State.

What Are Some of the Benefits of Anaerobic Digestion?

One of the major advantages of anaerobic digestion (AD) is the environmental benefits that accompany the technology. AD systems mitigate greenhouse gas (GHG) emissions, can contribute to reducing nutrient export from dairies to surface and ground water, can reduce the risk of pathogen spread, and can improve air quality. In the field of economics, many of these types of environmental benefits and harms fall into the realm of market externalities. Externalities are outputs of a production process that are “external” to the producers’ decision-making process, such as methane emitted from a manure lagoon. A common way governments have attempted to reduce harmful environmental externalities is through emissions regulations. An alternative way to mitigate negative externalities that we have seen in recent years has been the formation of markets for environmental attributes. This induces producers to internalize the environmental costs and benefits of production. Existing environmental markets contribute revenue gains to AD adopters, and with further development have the potential to result in even larger revenue gains for AD projects.

What did we do?

We explored available and potential environmental credits that could be available to AD projects and classified them by environmental attribute. These include carbon credits, renewable energy / fuel credits, tax and utility credits, and nutrient credits. We present examples of types of these environmental credits and their impacts on AD project profitability under various scenarios. We further discuss questions of eligibility and considerations for project developers and managers in the context of positioning for future environmental credit opportunities.

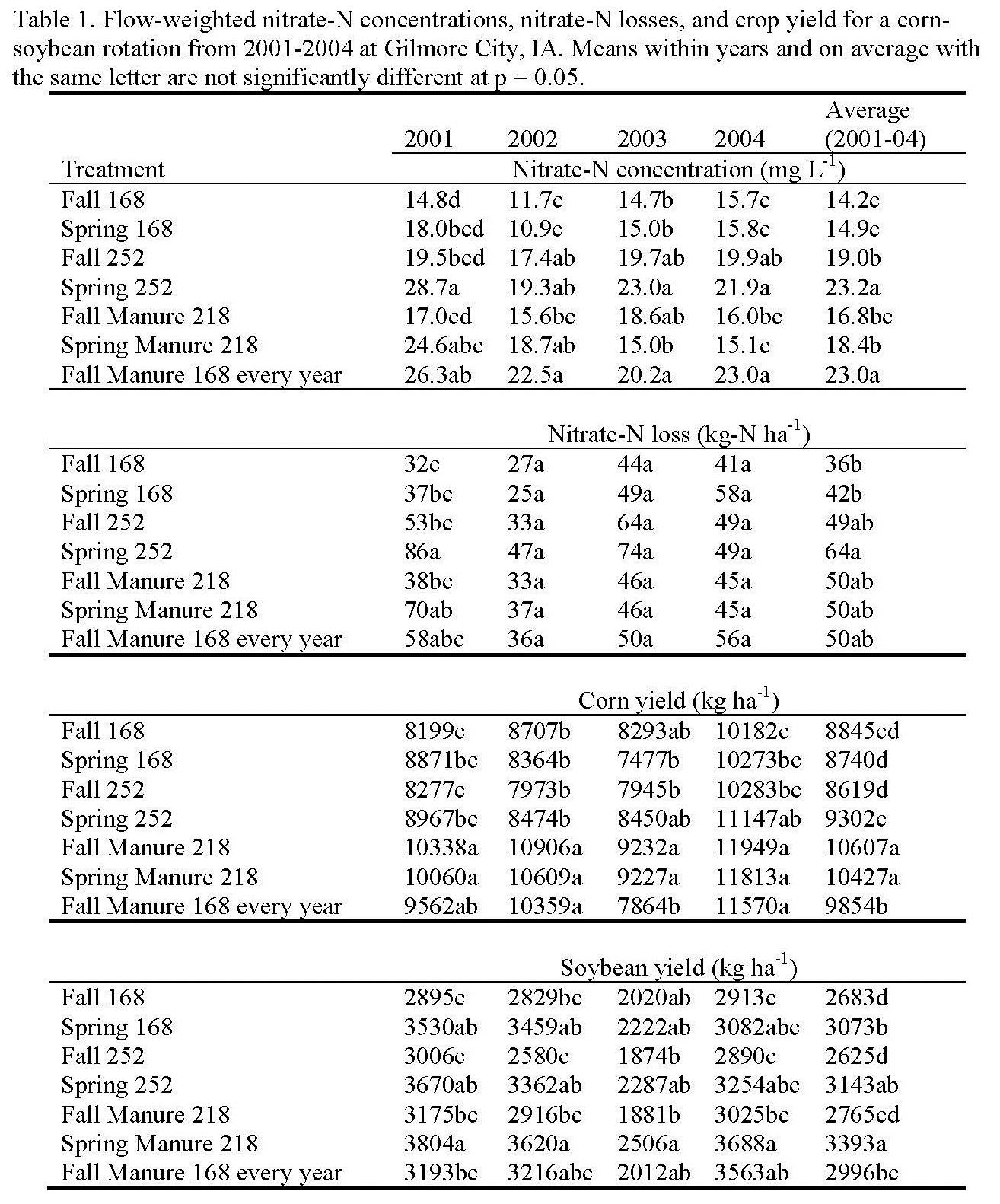

| AD Methane Use | Environmental Credit | Market Price | Yearly Revenue $/Head | Market Price | Yearly Revenue $/Head | Market Price | Yearly Revenue $/Head |

|---|---|---|---|---|---|---|---|

| Low Scenario | Medium Scenario | High Scenario | |||||

| Combined Heat & Power | Carbon Credit | $10/tCO2e | $42.13 | $15/tCO2e | $63.19 | $20/tCO2e | $84.25 |

| REC | $2.00/MWh | $3.08 | $4/MWh | $6.16 | $8/MWh | $12.32 | |

| Compressed Natural Gas | Carbon Credit | $10/tCO2e | $42.13 | $15/tCO2e | $63.19 | $20/tCO2e | $84.25 |

| RIN | $0.005/Mbtu | $158.34 | $0.01/Mbtu | $316.68 | $0.02/Mbtu | $633.36 | |

| LCFS | $12/tCO2e | $380.02 | $24/tCO2e | $760.04 | $48/tCO2e | $1,520.07 | |

What have we learned?

Environmental crediting options are highly variable both in terms of the types and mechanisms for the credit and their availability across space (jurisdiction) and time. History indicates there is likely to be continued variability and limited predictability for environmental crediting. Economic analyses show that AD projects can be profitable under many different scenarios, but is most sustainable when it allows for multiple revenues from electricity or renewable fuel, fiber products, nutrients, and carbon credits for avoided methane emissions. Environmental incentives like carbon credits and RFS credits (i.e., RIN) have a significant contribution to the profitability of an AD project, particularly when the project produces renewable natural gas.

| Products | AD-Combined heat and power (CHP) | AD-Boiler | AD-Renewable natural gas |

|---|---|---|---|

| Energy1 | -$2.1 million | NA | -$4.8 million |

| Energy, and fiber and nutrients | $4.8 million | $1.3 million | $1.5 million |

| Energy, fiber and nutrients and environmental incentives2 | $8.0 million | $3.6 million | $4.1 million |

| Note: NA – means not applicable for AD-Boiler Project because it does not produce electricity. 1Energy refers to electricity produced by the AD-CHP and AD-Boiler Projects, and electricity and renewable natural gas produced by the AD-RNG Project. 2Environmental incentives include the: Washington Energy Initiative, Renewable Energy Certificates, and carbon credits. |

|||

Future Plans

We will be publishing a Fact Sheet through WSU Extension providing more detailed discussion of environmental credits for AD projects. This fact sheet is part of an Anaerobic Digestion Systems Manual under development with support from USDA NIFA.

Authors

Chad Kruger, Director, WSU CSANR cekruger@wsu.edu

Greg Astill, Graduate Student WSU Econ; Suzette Galinato, Research Associate, WSU IMPACT Center; Craig Frear, Assistant Professor, WSU Biological Systems Engineering; Georgine Yorgey, Associate in Research, WSU CSANR; Jim Jensen

Additional information

Coppedge, B., G. Coppedge, D. Evans, J. Jensen, E. Kanoa, K. Scanlan, B. Scanlan, P. Weisberg and C. Frear. 2012. Renewable Natural Gas and Nutrient Recovery Feasibility for DeRuyter Dairy: An Anaerobic Digester Case Study for Alternative Off-take Markets and Remediation of Nutrient Loading Concerns within the Region. A Report to Washington State Department of Commerce. <http://csanr.wsu.edu/publications/deRuyterFeasibilityStudy.pdf>.

Galinatto, S.P., C.E. Kruger, and C.S. Frear (2015). Anaerobic Digester Project and System Modifications: An Economic Analysis. WSU Extension Publications EM090

Acknowledgements

The preparation of this fact sheet was funded by the WSU ARC Biomass Research Program, and USDA National Institute of Food and Agriculture Award #2012-6800219814.

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2015. Title of presentation. Waste to Worth: Spreading Science and Solutions. Seattle, WA. March 31-April 3, 2015. URL of this page. Accessed on: today’s date.

Outputs of This Project:

Outputs of This Project:  Amino Acid Supplementation: Studies confirmed that crude protein can be replaced with feed grade AA to meet the requirement of the first 5 limiting AA without negatively impacting growth performance or carcass composition when diets are formulated on a NE basis; however, further CP reductions resulted in more variable growth performance.

Amino Acid Supplementation: Studies confirmed that crude protein can be replaced with feed grade AA to meet the requirement of the first 5 limiting AA without negatively impacting growth performance or carcass composition when diets are formulated on a NE basis; however, further CP reductions resulted in more variable growth performance.

Air emissions

Air emissions