A vital component of liquid livestock and poultry manure collection and handling systems is storage capacity for the collected manure and associated material(flush water, wasted feed, etc.). This manure storage capacity is typically in the form of under-floor pits or outside storage tanks or ponds and/or treatment lagoons. These structures accumulate collected wastes and allow the waste management system operator to move away from a “daily scrape (collect) and haul” situation. This reduces time and labor needed for final disposition (either land application or off-farm “value-added” processing) of these manure accumulations.

What Is a Liquid Manure System?

“Liquid” livestock manure collection and handling systems are actually “fluid” livestock manure collection and handling systems. These systems are selected based upon the consistency or “thickness” of the manure and its flow characteristics. Manure flow characteristics are highly dependent on “solids content” or “percent solids” of the manure volume.

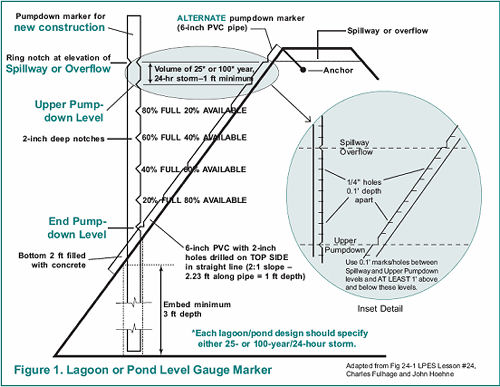

Liquid manure storage volume size depends on the amount of time in a year that is not available for land application or other manure utilization strategies. This is the design storage period. Land application time depends on growing season of the target crop(s) and local weather. Manure storage volume should be emptied by the end of the design storage period to be able to hold the expected amount of manure accumulation during the next storage period.

This web page deals with two general categories of liquid systems:

- Pits or slurry systems for storage only

- Lagoons with both slurry/wastewater storage and treatment (see National Center White Paper summary, Manure Management Strategies).

Types of Manure

“As-excreted” livestock manure moisture content changes as it moves through the collection process into storage. Liquid collection and handling systems add waste drinking water, wash water, flush water, rain, and stormwater runoff, lowering solids content below the 15% level typically used to define “solid” manure. A manure volume of 5 to 15% solids is “slurry” manure, with consistency and flow characteristics similar to thick chocolate malt. Manure volumes with 0 to 5% solids content have consistency and flow characteristics similar to water.

What Is the Difference Between Storage and Storage With Treatment?

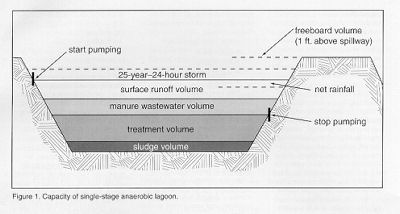

Contrasting storage and storage w/treatment, a manure containment structure which is emptied at the end of the storage period is essentially a storage structure. A lagoon has storage volume but will also have a permanent pool for residual treatment volume that provides a bacterial seed bed for continual bacterial action at an elevated level. This permanent pool is not considered in the design of a structure used for storage alone. Essentially whatever goes into a properly managed storage structure is what is pumped out. A lagoon, however, is designed to promote decomposition of organic matter entering the lagoon. For this reason, a lagoon is much larger than a storage pond.

Management of Lagoons

A manure containment structure which is not emptied at the end of the storage period is being operated as a lagoon, whether designed that way or not. Storage operated in this manner becomes a smelly, overloaded lagoon. Generally, when agitation is used to put settled or floating solids into suspension before pumping out the effluent, or the slurry, the structure is being operated as storage.

Digested solids do accumulate in a lagoon and should be removed once every ten or more years, or as specified by the system design to restore residual treatment volume. In rare circumstances, particular to specific lagoons approaching this restoration point, some engineers recommend some agitation during normal pumpout to remove some of this accumulation. Routine pumping from the storage volume portion of a lagoon involves only wastewater (<5% solids) and requires no agitation.

Related Web Pages

- Earthen Manure Containment Structures

- Role of Solid Liquid Separation in Manure Storage

- Liquid Manure Storage Ponds, Pits, and Tanks

- Liquid Manure Treatment Lagoons

Recommended Educational Resources

National Center for Manure and Animal Waste Management white paper summary, Manure Management Strategies published by North Carolina State University. A two page Executive Summary is available. The full white paper can be ordered from Midwest Plan Service, Iowa State University.

Page Managers: Ted Tyson, Auburn University, tysontw@auburn.edu and Saqib Mukhtar, Texas A&M University, mukhtar@tamu.edu .