To be sustainable, producers need to conserve energy while still maintaining or improving their facilities and the lives of the animals they house. This presentation was originally broadcast on January 19, 2024. Continue reading “Animal Feeding Operations Air Emission Estimation Methods”

Energy Conservation in Livestock and Poultry Operations

To be sustainable, producers need to conserve energy while still maintaining or improving their facilities and the lives of the animals they house. This presentation was originally broadcast on December 15, 2023. Continue reading “Energy Conservation in Livestock and Poultry Operations”

Improving Air Quality In and Around Livestock Facilities

Air quality in and around barns can negatively impact animal and worker welfare. This webinar will discuss ways to overcome these challenges. This presentation originally broadcast on April 21, 2023. Continue reading “Improving Air Quality In and Around Livestock Facilities”

Quantification of greenhouse gas emissions from US dairy farms

Purpose

Dairy farming is known to emit greenhouse gases (GHG), both from direct and indirect emission sources. Carbon dioxide (CO2) is emitted from the combustion of deep sequestered fossil fuel while non/temporarily sequestered, biologically mediated, methane (CH4) and nitrous oxide (N2O) are emitted by various sources, most notably by cattle, feed production, and manure management.

Dairy farmers and their key advisors, the balance of the dairy value chain, policy makers, government officials, non-governmental organizations (NGOs), and astute consumers value best available information about the greenhouse gas (GHG) emissions associated with milk production. In 2020, the Innovation Center for US Dairy (IC) set three 2050 environmental stewardship goals spanning from cradle to processor gate (i.e., milk production and milk processing), including GHG neutrality. Further, the IC committed to outwardly reporting on progress towards the goals every five years starting in 2025.

What Did We Do?

Work focused on the cradle to farm gate (milk production) segment of the overall GHG neutrality goal. A list of considerations deemed important to conduct a robust US dairy GHG analysis was developed and evaluated. The most important key considerations determined were geographic-driven factors and assessment focused approach (i.e., sampling farm population, not sampling). Boundaries for the four areas making up a cradle to farm gate categories for analysis – Cattle (Enteric), Feed, Manure, and Energy – were developed based in part on understanding of where available data is housed and managed by farmers and their custom operators and following Life Cycle Assessment (LCA) practices.

What Have We Learned?

The most important lesson learned was that sampling a farm population and scaling results to represent the US dairy industry GHG emission footprint cannot be used for multiple reasons. First, classical statistics requires a sample needs to be normally distributed about the mean – herd size is not normally distributed among farm size, 80 % cows owned by 20% of the farms and milk production is higher, between 3,000 and 5,000 lbs./cow annually, for larger herds. Second, the data needed from every farm doesn’t exist today. Third, random sampling of MILK and COWS is required, however, farmers are surveyed. Fourth, accurate emission results require a percentage of cows surveyed and the percentage of milk surveyed to be the same; however, the estimated probably is less than 0.0001 that this would occur (once in every 10,000 years if annual surveys were conducted). Lastly, analysis showed that unavoidable and unpredictable error resulted when scaling up sample analysis results to the US dairy population, meaning that a reported carbon dioxide equivalent (CO2e) value would have tremendous uncertainty in direction and magnitude. This is especially challenging when measuring progress toward the 2050 GHG neutrality goal; a population sampling and scaling based approached can result in higher calculated emissions in five years over a current value, even though many farms made notable changes to reduce GHG emissions.

Leaders of the US dairy industry were educated on the challenges of farm sampling and scaling. As a result, the decision was made to approach quantification of the progress toward the 2050 GHG neutrality goal using an approach that removes the need for scaling. That approach is called USDA Cow and Milk Data Focused approach.

Future Plans

Measurement of US dairy’s progress towards its 2050 GHG neutrality goal will be made using the USDA Cow and Milk Data Focused approach; first report on progress due in 2025.

Authors

Curt A. Gooch, Sustainable Dairy Product Owner, Land O’Lakes – Truterra

Corresponding author email address

Additional author

Roger Cady, Freelance Sustainability Consultant (Retired from industry)

Acknowledgements

Dairy Management Incorporated and the Innovation Center for US Dairy Environmental Stewardship Committee

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2022. Title of presentation. Waste to Worth. Oregon, OH. April 18-22, 2022. URL of this page. Accessed on: today’s date.

Anaerobic Co-digestion of Agro-industrial Feedstocks to Supplement Biogas Produced from Livestock Manure

Purpose

Anaerobic digestion (AD) is commonly used in agriculture to break down livestock manure and produce a sustainable source of energy by producing biogas, which is predominantly methane. Digestion of livestock manure can be supplemented with additional agricultural or industrial organic waste, potentially adding sources of revenue to the farm or digestion facility through tipping fees and additional biogas production. However, quantifying the anticipated impact on digester performance and operation is challenging, particularly as some potential feedstocks have not been studied previously. Understanding how a feedstock might impact a digester’s performance is critical, as digester upsets can lead to loss of revenue or even digester failure.

What Did We Do?

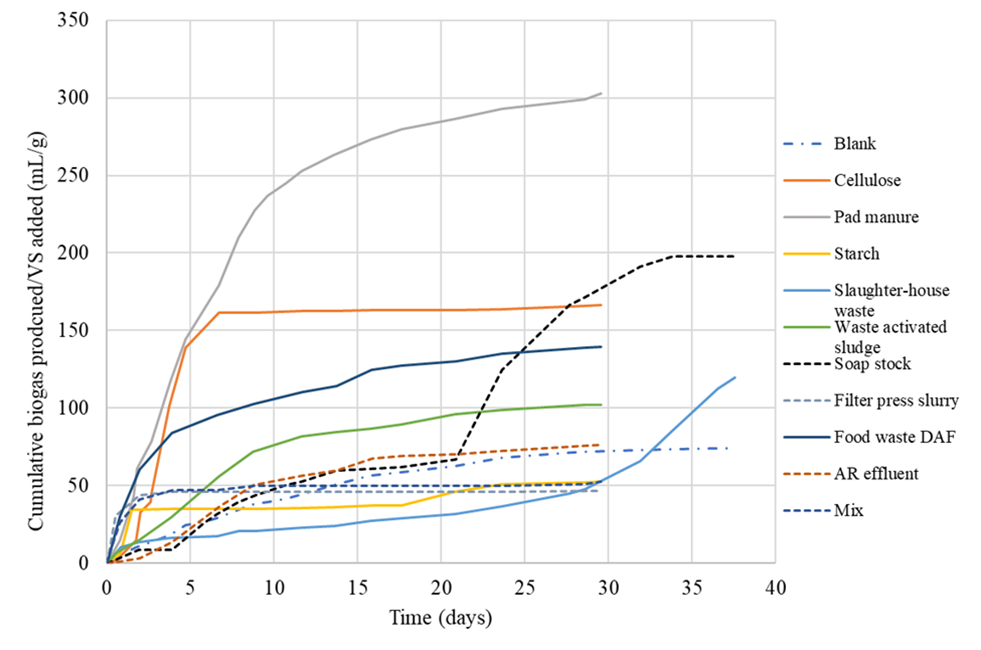

We conducted a set of mono-digestion biomethane potential experiments of several feedstocks currently in use at an agricultural AD facility that accepts mixed industrial waste streams in addition to digesting beef manure. The mono-digestion studies used triplicate 1-L working volume batch digesters which ran for 30-38 days. We tested beef manure, off-spec starch from food manufacturing, slaughterhouse wastewater treatment sludge, waste activated sludge from a corn processing facility, soap stock from glycerin refining, filter press slurry from a food grade water treatment facility, and food waste dissolved air flotation sludge. We also included a treatment for the effluent from the digester’s ammonia recovery system and a mixture of all the feedstocks at the same time. A blank (inoculum only) and positive control (cellulose with inoculum) digester were included as controls. This set of studies is described here as Experiment 1 (E1).

We then conducted a set of co-digestion biomethane potential tests combining the manure pairwise with some of the industrial feedstocks, specifically starch, slaughterhouse waste, soap stock, and filter press slurry (Experiment 2 or E2). These combinations were made at two different ratios of the two feedstocks. The first set of treatments combined the manure and an additional substrate at a 1:1 ratio on a volatile solids basis. The second set of treatments combined the feedstocks proportional to the amounts commonly used in the AD facility providing the materials. A final treatment pairing starch and soap stock at a 3:1 ratio was also included. These co-digestion treatments were conducted in triplicate alongside a single mono-digestion treatment of each feedstock for comparison. Finally, we examined the potential synergistic or antagonistic impacts of these combinations on methane yield and production rate. This was done by comparing the measured methane production at each time point compared to the expected methane production if the feedstocks each contributed additively to the methane production.

What Have We Learned?

Figure 1 shows the cumulative specific biogas production on a volatile solids basis for the mono-digestion experiment (E1). Some feedstocks, such as soap stock and slaughterhouse waste, experienced a substantial lag phase at the beginning of the experiment, which may have been due to the high levels of lipids and proteins.

During the co-digestion experiment (E2), we observed both total yield and kinetic synergy in all treatments. Only two digesters (one of the replicates from the starch and manure proportional treatment and one from the starch and soap stock treatment) produced substantially less (<30%) methane than would be expected for an additive effect for more than one day. This effect can be seen in Figure 2, which shows the cumulative methane curves (corrected for inoculum contribution and averaged over the three replicates) of the mono-digestion digesters for manure and starch individually and the curves for both co-digestion treatments using both manure and starch. Figure 3 shows the same curves for the co-digestion of manure and slaughterhouse waste. These co-digestion treatments show that combining the feedstocks causes an increase in methane production at a faster rate. They also show that co-digestion alleviates the lag phase experienced by the slaughterhouse waste.

Future Plans

We plan to continue exploring the impact of co-digestion on methane yield and production rate by using additional combinations of these feedstocks and exploring the impact of macromolecular composition (percentages of carbohydrates, proteins, and lipids) on synergistic effects. These results will help inform current or future agricultural AD operators regarding the use of co-digestion feedstocks for optimal energy production and best practices in selecting new feedstocks for co-digestion.

Authors

Jennifer Rackliffe, Graduate Research Fellow, Purdue University

Corresponding author email address

Additional authors

Dr. Ji-Qin Ni, Professor, Purdue University; Dr. Nathan Mosier, Professor, Purdue University

Additional Information:

https://www.sare.org/wp-content/uploads/2021-NCR-SARE-GNC-Funded.pdf

Acknowledgements:

This material is based upon work that is supported by the National Institute of Food and Agriculture, U.S. Department of Agriculture, under agreement number 2020-38640-31522 through the North Central Region SARE program under project number GNC21-334. USDA is an equal opportunity employer and service provider. Any opinions, findings, conclusions, or recommendations expressed in this publication are those of the author(s) and do not necessarily reflect the view of the U.S. Department of Agriculture. We also thank Purdue’s Institute for Climate, Environment and Sustainability for supporting the dissemination of this work. Finally, we acknowledge the assistance of Gabrielle Koel, Kyra Keenan, Amanda Pisarczyk, and Emily McGlothlin in conducting the laboratory work.

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2022. Title of presentation. Waste to Worth. Oregon, OH. April 18-22, 2022. URL of this page. Accessed on: today’s date.

The Role of Manure for Dairy Carbon Neutrality Targets: An Environmental Assessment of Organic Farms

Purpose

Different dairy associations and cooperatives have been establishing aggressive environmental goals, including reaching carbon neutrality. Carbon sequestration has been largely absent from environmental dairy studies as it is challenging to estimate. The daily feed intake of dairy cows under organic management is composed mainly of pasture and forages, which have a significantly more developed root system than many other grain cropping systems usually included in conventionally managed feed rations. Moreover, manure is also an important source of carbon, that could be sequestered in the long-term depending on the farm’s management practices. This paper quantifies GHG emissions from organic dairy farms in the U.S., including the benefits of carbon sequestration from above and below ground residues.

What Did We Do?

The U.S. was divided into eight regions based on U.S. climate categories and management practices of the organic dairy farms that participated in the study. This paper presents the results for the Midwest-Great Lakes, New England, California, and the Northwest, where representative organic farms and management practices for each region are modeled with life cycle assessment (LCA) techniques to estimate GHG emissions (kg CO2-eq). The model keeps track of key constituents in milk, meat, and manure based on the defined feed ration and animal characteristics. All inputs and outputs at the farm level during feed production, herd management, milking, and manure management are included in the analysis. Results are expressed per 1 kg of fat and protein corrected milk (FPCM), adjusted to 4% fat and 3.3% protein.

A novel approach has been developed to estimate carbon sequestration from carbon staying in the field that considers environmental factors such as temperature and farm management practices that affect the carbon content of manure reaching the soil and posterior sequestration. Three major steps are used to estimate C sequestration from the pasture and crops portion of dairy feed in the modeled organic systems: i) estimate the C added to the soil from biomass in above ground residues, below ground residues, and manure; ii) estimate the change in C above and below ground as a result of crop and grassland management practices, iii) determine the amount of C from the first steps that will be sequestered long-term.

What Have We Learned?

Average GHG emissions for the modeled farms and regions range from 0.76 – 1.08 kg CO2-eq/kg FPCM after accounting for C sequestration. Enteric methane (CH4) represents more than half of total GHGs and is closely related to the efficiency of conversion of feed to milk by the cow. Carbon sequestration benefits reduce overall emissions by 7 – 20% in the modeled farms and regions. Farms in the Midwest and New England rely heavily on pasture during the grazing season and on grass forages produced on-farm during the non-grazing season, meaning that most of the C is sequestered through residue that stays in the soil system (42 – 49% from below ground residue vs. 35 – 42% from manure). The addition of carbon in manure is also significant, contributing more carbon to the soil than below ground residue in some farms, especially in those relying on imported feeds (43 – 47% from manure in California and the Northwest).

Future Plans

GHG emissions, ammonia emissions, resource depletion (energy, land, and water) and eutrophication potential of organic dairy farms will be estimated for the remaining regions in the U.S. The effect of alternative management practices, key to organic practices, will also be modeled to identify mitigation strategies. Finally, different LCA modeling decisions, such as allocation and use of enteric CH4 predictive equations, will be evaluated to determine their effect on final results.

Authors

Horacio Andres Aguirre-Villegas, Associate Scientist, Department of Biological Systems Engineering, University of Wisconsin-Madison

Corresponding author email address

Aguirreville@wisc.edu

Additional authors

Rebecca A. Larson, Associate Professor. Department of Biological Systems Engineering, University of Wisconsin-Madison

Nicole Rakobitsch, CROPP, Organic Valley.

Michel A. Wattiaux, Professor, Animal and Dairy Sciences, University of Wisconsin-Madison

Erin, Silva, Associate Professor, Plant Pathology, University of Wisconsin-Madison

Acknowledgements

This work was funded by the Cooperative Regions of Organic Producers Pools (CROPP) Cooperative – Organic Valley

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2022. Title of presentation. Waste to Worth. Oregon, OH. April 18-22, 2022. URL of this page. Accessed on: today’s date.

Reporting 15 year’s of experience in WISE Aeration at manure and wastewater treatment ponds (updated)

Purpose

This presentation offers information about a low-energy high-performance manure and/or wastewater aeration technology. Referred to as “Widespreading Induced Surface Exchange” (WISE) aeration, its performance is from 4 to 10 times more efficient per watt of energy used compared to traditional bubble blower technology for aeration. Even though Aeration is well known to provide extensive odor reduction or elimination, its use has not been implemented because of the high energy costs associated with running blowers. This explains why very little is published about other value offered by aeration. The presentation discusses WISE aeration, many unexpected benefits, and unstudied results.

This presentation will quickly review the 2019 Waste to Worth presentation previously offered and will then offer additional information learned in the past 3 years, including approximately 20 key points. For those wanting to visit an actual working site before or after the conference, equipment is installed at a regional composting facility approximately 1 hr away from the Waste to Worth facility, near Wauseon OH.

What Did We Do?

Different manufacturers have created “floating aerators” over the past decades. Some have different issues than others, but all are installed in one of the most hostile environments at any enterprise. PondLift brand equipment has been installed at various farms, domestic wastewater treatment sites, and composting facilities to bring their ponds into full aerobic treatment, with most sites desiring odor elimination, while also allowing their effluent to be sent to growing crops through irrigation equipment, lowering their effluent handling costs while increasing the value of their effluent since it is often foliar fed, offering as much as 70% yield increase per unit of fertilizer. The author has been at each site to maintain equipment and learn more of its performance and learn more about results, expected and unexpected. Among the PondLift equipment installations, there are 3 pond installation sites in Ohio, and another at a dairy farm near Paw Paw MI, easily visited for those who would want to personally visit such sites. Other sites are further distance from Ohio.

What Have We Learned?

The installations have confirmed that odor elimination is very much possible through low-energy-use WISE aeration, while also preparing the effluent to be used by irrigation equipment for foliar feeding. Although Odor elimination is valuable, probably the most environmentally valuable result of aeration was the dramatic change in texture of the effluent (in both liquids and solids) so that when applied by traditional means, being “knifed in”, the treated manure was absorbed into the soil much faster than raw manure is absorbed into that soil. The timeframe is hours instead of days, reducing the potential runoff timeframe significantly, potentially eliminating significant runoff events. Given this observation at almost every site having WISE aeration, it became obvious that a method for quantifying the phenomena is needed, and this equipment needs to be defined so as to compare aerobically treated effluent to raw manure, preferably in a “side by side” process, while also being able to quantify manure runoff on different soil types, and different slopes of soils. While the presentation will also offer other phenomena data, the final portion of the presentation defines this equipment and procedures that might be adopted so as to study and quantify runoff, and compare runoff quantities to traditional distribution methods.

And for those who are interested in performing foliar feeding through automated manure nutrient distribution through irrigation equipment, the presentation will expand on several items recently identified, including the stratification that results from WISE Aeration, allowing irrigation without plugging pivot/circle nozzles. In addition, the presentation includes information about Struvite formation and its harvesting opportunity as well as control methods.

Future Plans

PondLift intends to offer equipment for use in studies focused on any phenomena of interest in manure or liquid waste treatment, as well as commercial use at farms. The political climate in future years will insist that potential runoff issues be addressed, updating Best Management Practices. In addition, it is now possible that manure odor be eliminated with a process which is financially feasible for farms.

A short discussion: Automation is valuable at farms. Bringing WISE Aeration to dairies and other farms which store liquid manure can help automate the manure storage/handling/disposal process. It is the opinion of the author that the small family dairy farm will continue to survive and thrive, given the advances in feeding/health/genetics at today’s farms, even though such farms offer a small percentage of milk products.

The fact that so many farms have limited potentially useable farm acres at small hilly locations, leads us to focus on improving their automation and reducing equipment and time spent on manure related work. To this end, work is progressing through PondLift, on a low cost “drop-in-place” sand separator which can easily be placed between the barn and the manure storage pit, allowing operators to remove sand before it gets to storage, which then allows the storage pit to be converted to aerobic treatment, which then allows automated manure nutrient distribution methods to be considered. Lastly, work continues through an associated enterprise on the SPEWPLI (self-propelled extremely-wide portable linear irrigator) which will be able to attach to a manure pumpers hose at a distant field, and distribute manure nutrients to the crop at the 1,500gpm rate often used by manure pumpers. This is important for farms which are more suited to pumping at high rates to distant fields.

Authors

John Ries, Managing Member PondLift LLC, retired professional engineer

Corresponding author email address

ries@iw.net

Additional Information

PondLift.com

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2022. Title of presentation. Waste to Worth. Oregon, OH. April 18-22, 2022. URL of this page. Accessed on: today’s date.

Greenhouse gas impacts resulting from co-digestion of dairy manure with community substrates

Purpose

The US Dairy industry established a voluntary environmental stewardship goal to achieve greenhouse gas (GHG) neutrality by 2050 among farmers and processors collectively. Manure management and enteric emissions combined account for approximately 70% of the GHG footprint of the US dairy industry, with nearly equal contributions from each (Thoma, 2013). There are multiple manure management systems used by dairy farmers in the Northeast and Upper Midwest that substantially impact GHG emissions. Quantification of GHG emissions for different manure management systems is necessary to compare options and strategies that can be applied to reduce GHG, especially methane, to move toward sustainability and reach the targets set by industry and governments.

Methane is the primary GHG emitted from the long-term storage of dairy manure, a water quality best management practice employed by many dairy farms today. Landfills are also a significant source of methane emission primarily due to degradation of organic waste, notably pre- and post-consumer food wastes (community substrates). Methane is a highly potent GHG that impacts warming by 25 – 28 times as much as carbon dioxide (CO2) on a 100-year global warming potential (GWP) time scale (US EPA). However, because methane has a lifespan in the atmosphere of around 12 years, it has been accounted for on a 20-year GWP scale (84 times the impact of CO2) by the State of New York (Climate Leadership and Community Protection Act). Manure management systems that substantially reduce methane, such as the co-digestion of manure with food waste, can achieve significant reductions of the GHG emissions associated with milk production.

What Did We Do?

The GHG emissions resulting from the anaerobic co-digestion of raw dairy manure and community substrate (i.e., food processing waste mixture diverted from landfilling) in an equal mass of each (total mass basis) were calculated as part of a larger study comparing eight different manure management systems. The community substrate was modeled as 50% ice cream and 50% dog food by mass. Methane and nitrous oxide emissions were calculated with equations that use the mass flow of volatile solids (VS) and nitrogen through the co-digestion manure management system that included digestate solid-liquid separation using a screw press and the long-term storage of separated liquid. Carbon dioxide and methane associated with system energy use and energy production as pipeline-quality renewable natural gas (RNG), as well as landfill organics diversion were also calculated. The parasitic energy use (heat and electricity) of the digester and related manure management and biogas upgrading equipment was supplied on an average annual load basis by a portion of the biogas produced. The total net GHGs were summed using a CO2-equivalent (CO2e) methodology (both GWP100 and GWP20 were computed) and normalized on a per lactating cow per year basis. A sensitivity analysis of eleven variables was conducted to quantify the impact of each on the net GHG result.

What Have We Learned?

The co-digestion system net annual GHG impact was calculated to be −16 metric tons (MT) CO2e cow-1 (GWP100) and −43 MT CO2e cow-1 (GWP20). For the co-digestion mixture analyzed (50% liquid dairy manure, 25% ice cream, and 25% dog food), the anaerobic digester biogas production was 4 times greater than the biogas production for manure alone (on a per lactating cow basis). This significant energy production potential contributed an offset of 3.9 MT CO2 cow-1 year-1, assuming the net RNG after supplying the system’s parasitic energy usage displaced the CO2 emissions from combusting approximately 380 gallons of diesel. In comparison, a methane leakage (or loss) of 2% from the digester to RNG system was equivalent to 18% of the energy offset at GWP100 (0.7 MT CO2e cow-1 year-1) and 62% at GWP20 (2.4 MT CO2e cow-1 year-1). Despite the greater contribution of methane leakage at GWP20 on a CO2e basis, the methane offset from landfilling the community substrate also substantially increased, resulting in just a 5 – 6% increase in the net annual GHG (remaining net negative) when methane leakage was varied from 1 to 3% under both GWP time scales. The methane leakage amount was also the most sensitive variable studied for the co-digestion system and the relatively low impact on total net GHG indicates the effectiveness of this type of manure management system as a tool to reach net GHG neutrality.

Future Plans

A next step in the assessment of co-digestion of dairy manure and food waste diverted from landfills is to continue improvement of our Cornell Dairy Digester Simulation Tool that predicts biogas production from a variety of food wastes combined in different quantities with dairy manure. This tool will also allow for the economic feasibility analysis of different co-digestion system sizes and substrate mixtures, inclusive of tipping fee variation and energy generation options (electricity and RNG) and associated values. This work will help farmers assess the feasibility of implementing or participating in a co-digestion system for manure management.

In future work contingent on funding, we plan to conduct comprehensive field measurements of methane emissions from the long-term storage of raw manure, separated manure liquid, and digested effluent. The equations that calculate methane are gross and depend on volatile solid content and degradability of the stored material, as well as temperature and retention time. Verification of these equations and inputs will give more confidence in utilizing bottom-up calculations of GHGs from manure management practices.

Authors

Lauren Ray, Extension Support Specialist III, Cornell PRO-DAIRY Dairy Environmental Systems Program

Corresponding author email address

LER25@cornell.edu

Additional authors

Curt A. Gooch, Sustainable Dairy Product Owner, Land O’Lakes – Truterra; Peter E. Wright, Extension Associate, Cornell PRO-DAIRY Dairy Environmental Systems Program

Additional Information

More information on related work can be found on the Cornell University PRO-DAIRY website under Environmental Systems: https://cals.cornell.edu/pro-dairy/our-expertise/environmental-systems.

Thoma, G., J. Popp, D. Shonnard, D. Nutter, M. Matlock, R. Ulrich, W. Kellogg, D. S. Kim, Z. Neiderman, N. Kemper, F. Adom, and C. East. (2013). Regional analysis of greenhouse gas emissions from USA dairy farms: A cradle to farm-gate assessment of the American dairy industry circa 2008. Int. Dairy J. 31:S29–S40. https://doi.org/10.1016/j.idairyj.2012.09.010.

US EPA, https://www.epa.gov/ghgemissions/understanding-global-warming-potentials. Accessed 2/24/2022.

Climate Leadership and Community Protection Act. 2020. New York State Senate Bill S6599.

Acknowledgements

The Coalition for Renewable Natural Gas and the New York State Department of Agriculture and Markets provided a portion of the financial resources to support the development of this work.

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2022. Title of presentation. Waste to Worth. Oregon, OH. April 18-22, 2022. URL of this page. Accessed on: today’s date.

Emission of ammonia, hydrogen sulfide, and greenhouse gases following application of aluminum sulfate to beef feedlot surfaces

Purpose

Alum has been successfully used in the poultry industry to lower ammonia (NH3) emission from the barns. However, it has not been evaluated to reduce NH3 on beef feedlot surfaces. Additionally, it is not known how it would affect other common emissions from beef feedlot surfaces. The purpose of this study was to determine the effect of adding aluminum sulfate to beef feedlot surfaces on NH3, hydrogen sulfide (H2S), carbon dioxide (CO2), methane (CH4), and nitrous oxide (N2O) emissions.

What Did We Do?

Eight feedlot pens (30 animals per pen) at the U.S. Meat Animal Research Center feedlot were utilized. The pens had a central mound constructed on manure and soil and 3 m concrete apron by the feed bunk and cattle were fed a corn-silage based diet. Four pens (30 cattle/pen) had 10% (g g-1) alum applied to the 6 meters immediately behind the concrete bunk apron and four did not receive alum. The amount of alum added to the area was determined on a mass basis for a depth of 5 cm of feedlot surface material (FSM) using the estimated density of feedlot surface material for Nebraska feedlots (1.5 g cm−3). On sampling days, six representative grab samples were collected from the feedlot surface from the six-meter area behind the bunk apron in each pen; samples were combined within pen to make three representative replicates per pen (N=24). Each of the three pooled samples per pen were measured for pH, NH3, H2S, CH4, CO2, and N2O using petri dishes and wind tunnels in an environmental chamber at an ambient temperature of 25°C (77°F) and 50% relative humidity. Flux measurements for NH3, H2S, CH4, CO2, and N2O flux were measured for 15 minutes using Thermo Fisher Scientific 17i, 450i, 55i, 410iQ, and 46i gas analysis instruments, respectively. Samples were analyzed at day -1, 0, 5, 7, 12, 14, 19, 21, and 26.

What Have We Learned?

Addition of alum lowered pH of FSM from 8.3 to 4.8 (p < 0.01) and the pH remained lower in alum-treated pens for 26 days (p < 0.01). Although the pH remained low, NH3 flux was only lower (p < 0.01) at day 0 and day 5 for alum-treated pens compared to the pens with no alum treatment. Nitrous oxide emission was not affected by alum treatment (6.2 vs 5.7 mg m-2 min-1, respectively for 0 and 10% alum treated pens). Carbon dioxide emission was lower for alum-treated pens than non-treated pens from day 5 until the end of the study (p < 0.05), perhaps due to suppressed microbial activity from the lower pH. Hydrogen sulfide emission was higher (p < 0.05) from alum-treated feedlot surface material (0.8 mg m-2 min-1) compared to non-treated feedlot surface material (0.3 mg m-2 min-1), likely due to addition of sulfate with alum. Methane emission was also higher in alum-treated pens (173.6 mg m-2 min-1) than non-treated pens (81.4 mg m-2 min-1). The limited reduction in NH3, along with increased H2S and CH4 emission from the FSM indicates that alum is not a suitable amendment to reduce emissions from beef feedlot surfaces.

| Table 1. pH, ammonia (NH3), hydrogen sulfide (H2S), methane (CH4), carbon dioxide (CO2) and nitrous oxide (N2O) emission from feedlot surface material treated with 0 or 10% alum (g g-1 mass basis). | ||||||||||||

| pH | NH3 (mg m-2 min-1) |

H2S (mg m-2 min-1) |

CH4 (mg m-2 min-1) |

CO2 (mg m-2 min-1) |

N2O (mg m-2 min-1) |

|||||||

| Day | 0% Alum | 10% Alum | 0% Alum | 10% Alum | 0% Alum | 10% Alum | 0% Alum | 10% Alum | 0% Alum | 10% Alum | 0% Alum | 10% Alum |

| -1 | 8.1 | 8.3 | 229.6d | 515.9c | 0.3 | 0.4 | 136.3 x | 73.4w | 4,542 | 3,234 | 3.1 | 4.2 |

| 0 | 8.3a | 4.8b | 163.0c | 32.4d | 0.2 f | 1.8 e | 43.1 x | 193.8w | 4,372 | 5,294 | 2.9 | 1.8 |

| 5 | 8.5a | 6.3b | 279.5c | 83.6d | 0.4 | 0.5 | 84.1 x | 309.5w | 404y | 1,347z | 6.0 | 6.8 |

| 7 | 8.6a | 6.7b | 120.2 | 130.0 | 0.6 f | 1.2e | 53.4 | 61.7 | 468 y | 1,903z | 15.3 | 10.9 |

| 12 | 8.6a | 7.2b | 418.0 | 320.3 | 0.3 | 0.3 | 104.5 | 145.7 | 3,742y | 1,939z | 3.3 | 8.0 |

| 14 | 8.9a | 7.6b | 229.0 | 145.5 | 0.2 | 0.4 | 25.4x | 180.7w | 4,203y | 2,018z | 11.5 | 9.3 |

| 19 | 8.6a | 7.5b | 228.0 | 225.1 | 0.1 f | 1.1e | 132.3x | 254.7w | 5,999y | 3,116z | 6.9 | 5.8 |

| 21 | 8.4a | 7.2b | 232.0 | 257.0 | 0.5 | 0.8 | 81.9x | 250.0w | 4,324y | 2,477z | 2.2 | 1.9 |

| 26 | 8.6a | 8.0b | 584.5c | 319.9d | 0.1f | 0.7e | 72.2 | 92.9 | 5,534y | 3,540z | 4.7 | 2.9 |

| Within a parameter and day, different superscripts indicate a significant difference (p < 0.05) between the emissions from the feedlot surface material treated with 0% and 10% alum. | ||||||||||||

Future Plans

Future research will evaluate the use of aluminum chloride instead of aluminum sulfate to lower pH of FSM and retain nitrogen. Additionally, microbial amendments are being evaluated to determine if they can reduce gaseous emissions from the feedlot surface.

Authors

Presenting author

Mindy J. Spiehs, Research Animal Scientists, USDA ARS Meat Animal Research Center

Corresponding author

Bryan L. Woodbury, Agricultural Engineer, USDA ARS Meat Animal Research Center

Corresponding author email address

bryan.woodbury@usda.gov

Additional Information

For additional information about the use of alum as a feedlot surface amendment, readers are direct to the following: Effects of using aluminum sulfate (alum) as a surface amendment in beef cattle feedlots on ammonia and sulfide emissions. 2022. Sustainability 14(4): 1984 – 2004. https://doi.org/10.3390/su14041984

Acknowledgements

The authors wish to acknowledge USMARC technicians Alan Kruger and Jessie Clark for their assistance with data collection and analysis.

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2022. Title of presentation. Waste to Worth. Oregon, OH. April 18-22, 2022. URL of this page. Accessed on: today’s date.

NAEMS: How It Was Done and Lessons Learned

Building Environment and Air Quality – Presented by Al Heber

Development of Draft Emission Estimating Methodologies for AFOs: Process Overview – Presented by Ian Rumsy

National Air Emissions Monitoring Study Status Update – Presented by Bebhinn Do

Purpose

The National Air Emissions Monitoring Study, or NAEMS, was conducted from 2007 – 2010 to gather data to develop scientifically credible methodologies for estimating emissions from animal feeding operations (AFOs). It followed from a 2002 report by the National Academy of Sciences that recommended the development of the emission models. NAEMS was funded by the AFO industry as part of a 2005 voluntary air compliance agreement with the U.S. Environmental Protection Agency (EPA). The goals of the air compliance agreement were to reduce air pollution, monitor AFO emissions, promote a national consensus on emissions estimating methodologies, and ensure compliance with requirements of the Clean Air Act and notification provisions of the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA), and the Emergency Planning and Community Right-to-Know Act (EPCRA). Thus, the design of the study was based both on principles set forth by the National Academy of Sciences and on the needs of EPA and the AFO industry to satisfy the compliance agreement.

What Did We Do

NAEMS monitored barns and lagoons at 25 AFOs in 10 states for approximately 2 years each to measure emissions of ammonia, hydrogen sulfide, particulate matter, and volatile organic compounds. University researchers conducted this monitoring with EPA oversight. The types of AFOs monitored included swine, broiler chickens, egg-laying operations, and dairies. Participating AFOs made their operations available for monitoring for two years and cooperated with the researchers, industry experts, and EPA during the study.

In 2012, EPA used information gathered in NAEMS, along with information provided as part of a 2011 Call for Information, to develop draft emission models for some of the AFO sectors that were monitored. The EPA Science Advisory Board (SAB) conducted a peer review of these original draft emission models and made suggestions for improving the models. Since 2017, EPA began applying the SAB suggestions and developing new draft emission models for each AFO sector. The models estimate farm-scale emissions using information that producers already record or is easy to get (like weather data). The models are not “process-based.” However, the approach aims to estimate emissions from sources based on statistical relationships between air emissions and the meteorological and housing parameters collected that are known to affect processes that generate emissions. The development of process-based models remains a long-term goal of the agency, as we acknowledge process-based models improve the accuracy of emission estimates for the livestock and poultry sectors.

What Have We Learned

During the workshop, panelists will discuss in more detail the lessons learned at various stages of the NAEMS project and how those lessons could inform future work.

Future Plans

The EPA team continues to develop draft emission models using the NAEMS data. It is anticipated that the AFO emission models will be finalized after incorporating input from a stakeholder review period.

Authors

Presenting Authors

-

- Albert J. Heber, Professor Emeritus, Agricultural and Biological Engineering

- Ian C. Rumsey, Physical Scientist, Office of Research & Development, U.S. Environmental Protection Agency

- Bebhinn Do, Physical Scientist, U.S. Environmental Protection Agency

Corresponding Author

Bebhinn Do, Physical Scientist, U.S. Environmental Protection Agency

do.bebhinn@epa.gov

Additional Information

For updates on NAEMS, please see: https://www.epa.gov/afos-air/national-air-emissions-monitoring-study

Acknowledgements

U.S. Environmental Protection Agency – Office of Research & Development Emission Estimating Methodology development team: Maliha Nash, John Walker, Yijia Dietrich, Carry Croghan

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2022. Title of presentation. Waste to Worth. Oregon, OH. April 18-22, 2022. URL of this page. Accessed on: today’s date.