Purpose

Anaerobic digestion (AD) is commonly used in agriculture to break down livestock manure and produce a sustainable source of energy by producing biogas, which is predominantly methane. Digestion of livestock manure can be supplemented with additional agricultural or industrial organic waste, potentially adding sources of revenue to the farm or digestion facility through tipping fees and additional biogas production. However, quantifying the anticipated impact on digester performance and operation is challenging, particularly as some potential feedstocks have not been studied previously. Understanding how a feedstock might impact a digester’s performance is critical, as digester upsets can lead to loss of revenue or even digester failure.

What Did We Do?

We conducted a set of mono-digestion biomethane potential experiments of several feedstocks currently in use at an agricultural AD facility that accepts mixed industrial waste streams in addition to digesting beef manure. The mono-digestion studies used triplicate 1-L working volume batch digesters which ran for 30-38 days. We tested beef manure, off-spec starch from food manufacturing, slaughterhouse wastewater treatment sludge, waste activated sludge from a corn processing facility, soap stock from glycerin refining, filter press slurry from a food grade water treatment facility, and food waste dissolved air flotation sludge. We also included a treatment for the effluent from the digester’s ammonia recovery system and a mixture of all the feedstocks at the same time. A blank (inoculum only) and positive control (cellulose with inoculum) digester were included as controls. This set of studies is described here as Experiment 1 (E1).

We then conducted a set of co-digestion biomethane potential tests combining the manure pairwise with some of the industrial feedstocks, specifically starch, slaughterhouse waste, soap stock, and filter press slurry (Experiment 2 or E2). These combinations were made at two different ratios of the two feedstocks. The first set of treatments combined the manure and an additional substrate at a 1:1 ratio on a volatile solids basis. The second set of treatments combined the feedstocks proportional to the amounts commonly used in the AD facility providing the materials. A final treatment pairing starch and soap stock at a 3:1 ratio was also included. These co-digestion treatments were conducted in triplicate alongside a single mono-digestion treatment of each feedstock for comparison. Finally, we examined the potential synergistic or antagonistic impacts of these combinations on methane yield and production rate. This was done by comparing the measured methane production at each time point compared to the expected methane production if the feedstocks each contributed additively to the methane production.

What Have We Learned?

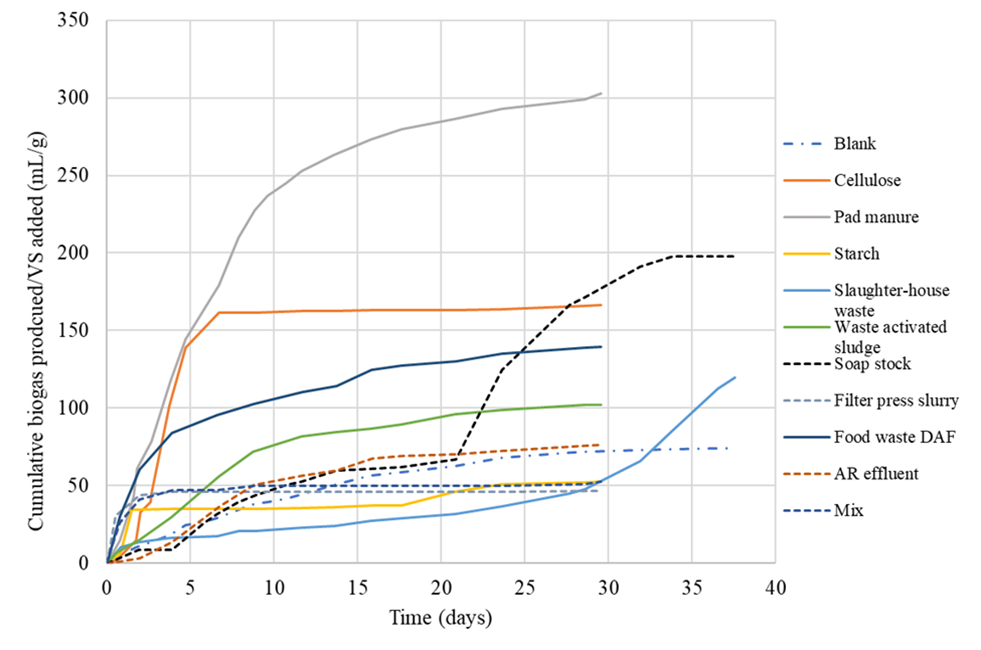

Figure 1 shows the cumulative specific biogas production on a volatile solids basis for the mono-digestion experiment (E1). Some feedstocks, such as soap stock and slaughterhouse waste, experienced a substantial lag phase at the beginning of the experiment, which may have been due to the high levels of lipids and proteins.

During the co-digestion experiment (E2), we observed both total yield and kinetic synergy in all treatments. Only two digesters (one of the replicates from the starch and manure proportional treatment and one from the starch and soap stock treatment) produced substantially less (<30%) methane than would be expected for an additive effect for more than one day. This effect can be seen in Figure 2, which shows the cumulative methane curves (corrected for inoculum contribution and averaged over the three replicates) of the mono-digestion digesters for manure and starch individually and the curves for both co-digestion treatments using both manure and starch. Figure 3 shows the same curves for the co-digestion of manure and slaughterhouse waste. These co-digestion treatments show that combining the feedstocks causes an increase in methane production at a faster rate. They also show that co-digestion alleviates the lag phase experienced by the slaughterhouse waste.

Future Plans

We plan to continue exploring the impact of co-digestion on methane yield and production rate by using additional combinations of these feedstocks and exploring the impact of macromolecular composition (percentages of carbohydrates, proteins, and lipids) on synergistic effects. These results will help inform current or future agricultural AD operators regarding the use of co-digestion feedstocks for optimal energy production and best practices in selecting new feedstocks for co-digestion.

Authors

Jennifer Rackliffe, Graduate Research Fellow, Purdue University

Corresponding author email address

Additional authors

Dr. Ji-Qin Ni, Professor, Purdue University; Dr. Nathan Mosier, Professor, Purdue University

Additional Information:

https://www.sare.org/wp-content/uploads/2021-NCR-SARE-GNC-Funded.pdf

Acknowledgements:

This material is based upon work that is supported by the National Institute of Food and Agriculture, U.S. Department of Agriculture, under agreement number 2020-38640-31522 through the North Central Region SARE program under project number GNC21-334. USDA is an equal opportunity employer and service provider. Any opinions, findings, conclusions, or recommendations expressed in this publication are those of the author(s) and do not necessarily reflect the view of the U.S. Department of Agriculture. We also thank Purdue’s Institute for Climate, Environment and Sustainability for supporting the dissemination of this work. Finally, we acknowledge the assistance of Gabrielle Koel, Kyra Keenan, Amanda Pisarczyk, and Emily McGlothlin in conducting the laboratory work.

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2022. Title of presentation. Waste to Worth. Oregon, OH. April 18-22, 2022. URL of this page. Accessed on: today’s date.