This webinar discusses why compaction is a cropping challenge, considers how the application of manure can lead to it, and the effects of manure on soil resiliency. This presentation was originally broadcast on April 19, 2024. Continue reading “Optimizing Agricultural Practices: Balancing Manure Use and Minimizing Compaction”

Energy Conservation in Livestock and Poultry Operations

To be sustainable, producers need to conserve energy while still maintaining or improving their facilities and the lives of the animals they house. This presentation was originally broadcast on December 15, 2023. Continue reading “Energy Conservation in Livestock and Poultry Operations”

Minimizing Risk on Livestock & Poultry Operations

In the Livestock and Poultry Environmental Learning Community, we are well aware that @#$% happens. In this webinar, presenters share insurance considerations and ways to minimize risk on livestock and poultry operations. This presentation was originally broadcast on November 17, 2023. Continue reading “Minimizing Risk on Livestock & Poultry Operations”

Carbon Markets for Livestock Operations: Producer Perspectives

The final in a series of 3 webinars, this presentation focuses on producer perspectives of carbon markets for livestock operations. This presentation originally broadcast on January 20, 2023. Continue reading “Carbon Markets for Livestock Operations: Producer Perspectives”

Carbon Markets for Livestock Operations: Manure Treatment and Handling

The first in a series of 3 webinars, this presentation introduces the fundamentals of carbon emissions, as well as technologies, practices and market opportunities available to agricultural producers are critical to that transition on the livestock operation. This presentation was originally broadcast on November 18, 2022. Continue reading “Carbon Markets for Livestock Operations: Manure Treatment and Handling”

Economics of Anaerobic Digesters for Processing Animal Manure

Digesters are of interest with regards to climate change, energy, air quality, and water quality. However, digesters are capital-intensive and difficult to maintain. Profitability of a farm-based digester usually requires utilizing the energy, carbon credits, tipping fees, and marketing other co-products such as manure solids that are separated out and composted.

The Environmental Protection Agency’s AgSTAR program has a website http://www.epa.gov/agstar/ with information to assist livestock producers who are considering installation of a digester. The website contains a database of farm digesters that are operating in the United States or that have operated in the past. It also provides a spreadsheet-based screening tool to help assess the potential feasibility of a project based on factors such as the feedstock, onsite conditions, the system type and size, and the planned biogas use.

What does a digester cost to install? Costs will vary widely depending on the situation, but the two sources discussed below show what some recent dairy farm digester installations have cost. The reports are the 2015 article by Manning and Hadrich, and the annual reports of the California Department of Food and Agriculture’s Dairy Digester Research and Development Program (CDFA).

The CDFA funded 117 dairy farm projects between 2015 and 2021. All but one of them were covered lagoon digesters (see the fact sheet by Hamilton for a discussion of digester types). Those funded in 2015 generated electricity, but most of those funded in 2017 and later have renewable natural gas (RNG) as the end-use of the biogas. The AgSTAR database lists the herd sizes for 19 of these digester projects that are producing RNG. For those projects, the average herd size was 7,479 cows and the average project cost was $947/cow or $4,384,479 total before deducting the CDFA grant. For the entire group of 117 projects, the CDFA grant funds covered 33 percent of the total cost.

The total cost of the greenhouse gas reductions achieved by these 117 projects was $30.94 per 1 metric ton of carbon dioxide equivalent including both the CDFA grants and the matching funds, or $9.88/1 metric ton considering only the CDFA grant funding. Those greenhouse gas reductions are calculated using methodology developed by the California Air Resources Board.

Manning and Hadrich report on 12 California dairy operations that had installed digesters and were using the biogas to generate electricity. They found that in 2014 the average initial cost of a lagoon system was $1.1 million ($869/cow with an average herd size of 2,496 cows) while a plug-flow system was $ 1.5 million ($1,114/cow and 1,620 cows). Subsidies covered around half of the initial investment on average.

The 12 Manning-Hadrich digesters included seven covered lagoon digesters and five plug-flow digesters. Seven of the digesters were providing benefits to the operations that exceeded their costs after subsidies. The other five were not operating profitably, including three of the plug-flows and two of the lagoon systems. Three of the unprofitable plug-flow digesters had ceased operation at the time of the study while the others were all operating. The seven profitable digesters had average annual operating costs of $0.98/cow while the five unprofitable ones averaged $2.72/cow.

Author: William F. Lazarus, University of Minnesota

Related:

Dairy Digester Research and Development Program (2022). Report of Funded Projects (2015-2022) 2022: Report to the Joint Legislative Budget Committee, California Department of Food and Agriculture, from https://www.cdfa.ca.gov/oefi/ddrdp/docs/2022_DDRDP_Legislative_Report.pdf.

Hamilton, D. (2019). “Types of Anaerobic Digesters.” Retrieved 8/4/22, 2022 from https://lpelc.org/types-of-anaerobic-digesters/.

Manning, D. T. and J. C. Hadrich (2015). “An evaluation of the social and private efficiency of adoption: Anaerobic digesters and greenhouse gas mitigation.” Journal of Environmental Management 154: 70-77.

U.S. AgSTAR. “AgSTAR: Biogas Recovery in the Agriculture Sector.” Retrieved 8/3/22, from http://www.epa.gov/agstar/.

-

Find these topics and many other related Farm Energy media resources at the Farm Energy Media archive.

Find these topics and many other related Farm Energy media resources at the Farm Energy Media archive.

Manure nutrient trends and creating dynamic “book values” through ManureDB

This webinar highlights ManureDB, a database of manure samples informing “book values”. Having current manure test numbers will assist in more accurate nutrient management planning, manure storage design, manure land application, and serve agricultural modeling purposes. This presentation was originally broadcast on June 17, 2022. Continue reading “Manure nutrient trends and creating dynamic “book values” through ManureDB”

Use of Vermifiltration as a Tool for Manure Management

This webinar discusses the science and economics behind the use of worms in the processes of composting (i.e., vermicomposting) and treatment of wastewater and manure liquid waste stream (vermifiltration). This presentation was originally broadcast on May 20, 2022. Continue reading “Use of Vermifiltration as a Tool for Manure Management”

Perceptions of Agricultural Stakeholders on Manure Use, Benefits, and Barriers

Purpose

Nutrient recycling is fundamental to agricultural systems (Spiegal et al., 2020). Integration of animal and crop production represents an example of the application of a circular economy to manage nitrogen (N), phosphorus (P), and other nutrients (Figure 1) important to crop and livestock production. An integrated system recycles these critical nutrients from animal feed to manure to soils and back to animal feed. Nutrient additions to the farm, like animals, feed, and fertilizer (input arrow), are necessary to offset the nutrients leaving the farm in animal protein products (output arrow), as well as other nutrient losses in the system (Cela et al., 2014). The efficiency of this nutrient recycling process has both environmental and economic sustainability implications.

For many regions of the United States, such as the Corn Belt, animal agriculture remains in relatively close proximity to sufficient crop production to allow agronomic recycling of nitrogen and phosphorus (Gollehon et al., 2001, 2016). However, the sources of manure nutrients (livestock and poultry operations) and the consumers of nutrients (cropland) are often managed as independent businesses. In other regions, separation of feed and animal production by distance and business boundaries creates significant challenges for agronomic nutrient recycling (Spiegal et al., 2020).

The willingness of crop farmers to accept manure as part of their fertility program is dependent upon their perceptions of the benefits and challenges associated with using manure. Likewise, behaviors among farmers and agricultural advisors of information-seeking – “purposive acquisition of information from selected information carriers” (Johnson 1996) – must be considered as a precursor to content delivery. Thus, in early 2020, a faculty team from University of Nebraska, University of Minnesota, and Iowa State University collaborated to implement a survey of farmers and their advisors to guide multi-state outreach programming by identifying:

-Challenges that regularly prevent manure’s use in crop production and

-Perceptions of manure’s benefits that may encourage manure transfers from livestock farmers to crop producers.

What Did We Do

A draft survey was tested with three groups (a stakeholder advisory group, the national Livestock and Poultry Environmental Learning Community, and the Nebraska Animal Manure Management team) leading to the final product. The survey was delivered electronically through QualtricsXM survey application tool using a University of Nebraska-Lincoln licensed product. The survey included questions for the participants on the following subjects of interest:

1. Participant’s role in manure decision making.

2. Perceptions and knowledge of manure’s benefits. Participants were asked to rate the degree to which they considered manure to be harmful or beneficial for crop fertility, soil physical characteristics, soil biological characteristics, crop yields, and environmental quality.

3. Perceptions and knowledge of manure’s challenges. Participants were presented with a list of potential barriers which might prevent manure use in crop fertility programs and asked to identify which factors were barriers for their operations, or for their advisees.

4. The types of supporting resources which would be of most value for the participants’ decision making or advising on manure benefits and barriers.

Surveyed Participants

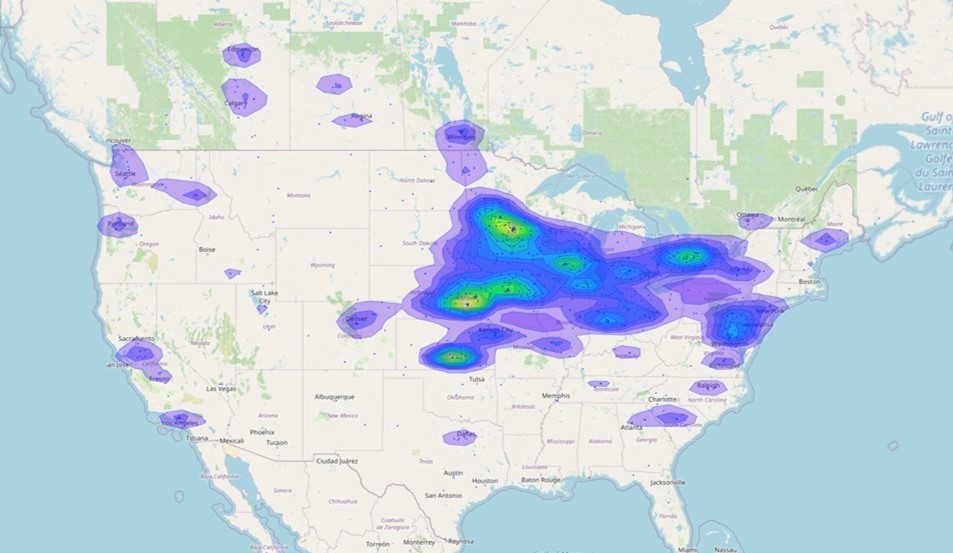

Responses were received from 793 individuals across the U.S. and Canada. The results are heavily weighted towards participants from the Corn Belt and the High Plains regions of the U.S. (44% and 23% of respondents, respectively). Survey participants were 87% male and 13% female. Participants’ experience were reported as 29% with less than 10 years, 22% with 11 to 20 years, and 49% with 21 years or more. Participants self-identified as a crop farmer (13%), animal feeding operation (AFO) (7%), professional advisor for crop fertility or manure management decisions (60%), or some combination of these three roles (20%). Crop farmers indicated that they were an annual user of manure (73%), user of manure within the past 3 years (9%), or user of manure within past 4 to 6 years (9%). Only 10% were not users of manure. Those identifying as advisors suggested that manure management is a primary focus of crop fertility advising (20%), frequent part of crop fertility advising (39%), or an occasional part of a crop fertility advising (36%). Only 4% of advisor responses indicated they did not include manure in their advising.

A series of five questions were presented to identify real or perceived challenges among respondents that represent potential barriers to using manure in crop fertility programs. Lists of agronomic, economic, neighbor or rural community, regulatory, and logistical challenges were presented based on outcomes of the project team’s advisory group discussions and reviews of previous surveys (Battel and Krueger, 2005; Case et al., 2017; Herrero et al., 2018; Poe et al., 2001). Lastly, respondents were asked to identify the types of supporting resources preferred for information-seeking on manure use in cropping systems.

What Have We Learned

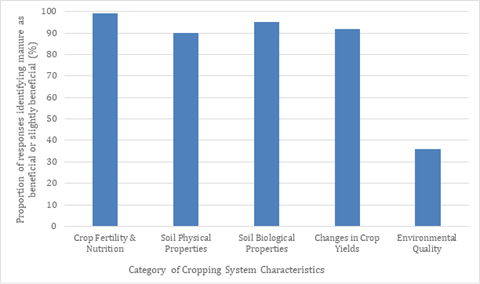

Perceptions and Knowledge of Manure Benefits. Both private sector advisors and crop farmers shared similar positive impressions of manure’s benefits for crop fertility, yield, and soil characteristics while being less positive regarding their impressions of how manure impacts environmental quality. Crop farmers and private sector advisors recognize the complementary role of manure and fertilizer in a fertility program at 74% and 76% frequency, and at slightly higher rates than all survey responses (71%). The complementary role of manure and fertilizer was also similar across regions (Corn Belt – 70%; High Plains-69%; all other regions – 74%).

The only audience factors that significantly (p<0.05) influenced participant attitudes toward manure benefits were that participants living in the corn belt were less likely to describe manure as beneficial or slightly beneficial for environmental quality (30%, compared to 46% for high plains, and 35% for all other regions). Similarly, we found that private sector advisors were significantly (p<0.05) less likely to describe manure as beneficial to environmental quality (27%, compared with 58%, 53%, and 30% for livestock producers, crop producers, or public sector advisors respectively). No statistical differences were observed for an influence of audience factors on attitudes towards manure benefits to any of the other characteristics of cropping system benefits (crop yield, soil physical properties, soil biological properties, and crop fertility). However, across all audience sectors participants were unlikely to indicate that they thought manure could be beneficial or slightly beneficial for environmental quality (Figure 2). This data suggests that respondents do not associate improved soil physical and biological characteristics with reduced risk for nutrient transport via runoff, erosion, and leaching. Manure and inorganic fertilizer were perceived as complementary to each other by 71% of respondents, while only 17% believed these two products compete.

Barriers to Manure Use. As with perceptions of benefits of manure use, audience factors had little effect on the perceived barriers to manure use. There was an observed tendency for more advisors to include most factors as barriers to manure use; however, this tendency was only significant (p<0.05) for six potential barriers: compaction, cost of manure transportation, odors, risks posed by manure application to food crops, accessibility of custom applicators, and use of public roads (Table 1). The overall ranking of barriers to manure use can be found in Table 2. Cost of transportation (68%), odor (58%), timeliness of nutrient availability (55%), concerns related to the field conditions for manure application (50%), and access to labor for manure application (48%) were most frequently indicated as barriers for manure use. Interestingly, several of these factors correspond to those where a difference in the level of concern was observed between advisors and producers (Table 1). However, when considering barrier ranking by agronomic role, 4 of the top 5 barriers are similar between farmers and advisors (cost of transportation, odor, timeliness, and labor availability). Farmers rate concerns with weed seeds as a top 5 barrier, while advisors do not, leaving concerns with field conditions for application as the 6th most selected by crop farmers. This similarity of ranking, even where statistical differences exist, indicates that there is agreement on what are the most significant barriers, but some difference in the perceived seriousness or scale of the barrier. In general, crop farmers less frequently indicated factors as barriers to manure use than did advisors.

Table 1: The frequency survey responses identified selected barriers for manure use. Letters indicated statistical differences in how participants with different roles in agronomic decisions perceived barriers of interest at the alpha = 0.05 level.

| Comparison by Role in Agronomic Decisions | Animal Feeding Operator (n=66) | Crop Farmer (n=120) | Private Sector Advisor (n=311) | Public Sector Advisors (n=196) |

| Compaction from application | 36%a | 41%a | 59%b | 40%a |

| Cost of manure application | 55%a | 67%ab | 84%bc | 85%c |

| Odors an air quality impairment | 44%a | 56%ab | 75%bc | 79%c |

| Manure application to food crop | 15%ab | 13%a | 20%bc | 22%c |

| Accessibility of custom applicators | 20%a | 19%ab | 40%b | 3%ab |

| Use of or crossing of public roads | 15%a | 11%a | 21%b | 13%a |

Table 2: The frequency all survey responses identified specific factors as barriers for manure use (n=793)

| Potential Barrier | % Who perceived as a barrier | Potential Barrier | % Who perceived as a barrier | Potential barrier | % Who perceived as a barrier |

| Transport | 68% | Water Quality | 35% | $ of Manure | 25% |

| Odor | 58% | Interference with Reduced Tillage | 34% | Accessibility | 25% |

| Timeliness | 55% | Neighbor Concerns | 34% | Legal Issues | 25% |

| Field Conditions | 50% | Equipment $ | 34% | Flies | 20% |

| Labor | 48% | Regulation $ | 32% | Interference with Specialty Crops | 19% |

| Low or Inaccessible Nutrients | 47% | Traffic | 31% | Risks to Food Crop | 15% |

| Low or Inaccessible Nutrients | 47% | Traffic | 31% | Risks to Food Crop | 15% |

| Compaction | 44% | Planning & Zoning | 31% | Road Access | 14% |

| Imbalanced Nutrients | 44% | Harm to Local Infrastructure | 28% | Foreign Materials | 9% |

| Uniformity | 38% | Stockpiles | 28% | Reduced Yield | 5% |

| Setbacks | 37% | Presence of Applicators | 27% | Harmful to Soil | 3% |

| Weed Seeds | 37% | Pollution | 27% |

Preferred Sources of Educational Materials. Among three broad groups of respondents (farmers, advisors, and educators), all identified their peers as an important source of information. Brief factsheets or news articles are identified by educators as their top resource they would use (81% of educator responses and 65% of advisor responses). Recommended research articles also ranked high among all three groups. At this point in time, social media (short videos, podcasts, and Twitter and Facebook) is a preferred resource for a smaller portion of these audiences (26% or farmers, 15% of advisors, and 47% by educators).

Table 3. Most valued resources for agronomic decision making

| Resource Type | Farmer (n=197) | Advisor (n=438) | Educator (n=95) |

| Recommended research articles | 49% | 53% | 55% |

| Brief fact sheet or news articles summarizing current science | 52% | 65% | 81% |

| Decision support tool | 34% | 39% | 43% |

| Short videos or podcasts summarizing current science | 20% | 12% | 36% |

| Scripted visuals and text for your use on Twitter, Facebook, other | 6% | 3% | 11% |

| Network of farmers (or advisors or educators) with whom you interact and share experiences | 62% | 61% | 62% |

| Scripted PowerPoint presentation for use in educational programs | — | — | 38% |

Future Plans

The intent of this survey was to help our project team and others better understand the characteristics of animal manures that are considered beneficial and barriers to future manure use. Recognition of these benefits and hurdles will be critical as the need to transfer manure nutrients from existing animal feeding operations to crop farms, many with limited previous history of using manure, expands. Matching educational and technical services to the perceptions that impede manure transfer will be necessary.

Future outreach programming should be designed to:

-

- Continue to build general awareness of the agronomic and yield benefits of manure.

- Focus on assisting AFO managers and advisors with communication of specific messages such as 1) desirable rates/plans to best meet crop N and P needs, 2) field-by-field estimation of manure’s fertilizer replacement value and nutrients contributing the greatest value, and 3) complementary manure and fertilizer recommendations for optimum yields.

- Focus on connecting improved soil health with improved water quality.

- Help farmers articulate among themselves and to their rural communities the water quality benefits of organic fertilizers when applied to meet agronomic needs of the crop.

- Challenges associated with manure that frequently become barriers to manure use should be addressed through research and outreach. Specifically, the authors wish to suggest that four challenges are commonly regarded as significant barriers to manure use and require focus to overcome:

- Transportation Costs: Businesses providing manure hauling and land application services will be important when transferring manure to fields more distant from manure sources, and educational experiences addressing the current costs of transporting manure and the comparative economic benefit achieved by individual fields will be important.

- Odor: A farmers’ desire to be a good neighbor is counter to their willingness to create odors for their neighbors. Farmer and advisor education and planning for reducing odor risks is critical. Technology options to forecast, assess, and address potential nuisance odors may help alleviate odor concerns resulting from manure application.

- Logistical Barriers: Three logistical issues ranking highest include 1) timeliness of manure application; 2) time/labor availability; and 3) field conditions restricting manure application. Business services for transporting and land applying manure as well as manure brokering services can address many logistical challenges. Alternative application time windows, such as side dressing a crop with manure, will also be valuable.

- Agronomic Issues: Manure application comes with a history of agronomic concerns such as compaction, poor uniformity, and potential for weed seed and herbicide resistance concerns. Many issues are likely to be regionally and manure source specific, thus the need to adapt agronomic education to local needs. Education and business services that encourage technologies such as precision manure application and related technologies, designer manures, and manure treatment may have value based upon regional needs. A 4Rs strategy (right rate, source, time, and place) for manure, similar to what is being promoted in the fertilizer industry, may be beneficial.

Authors

Amy Millmier Schmidt, Associate Professor, University of Nebraska-Lincoln

aschmidt@unl.edu

Additional Authors

-Mara Zelt, Schmidt Lab Project Director, University of Nebraska-Lincoln;

-Daniel Andersen, Associate Professor, Iowa State University;

-Erin Cortus, Associate Professor, University of Minnesota;

-Richard Koelsch, Emeritus Professor, University of Nebraska-Lincoln;

-Leslie Johnson, University of Nebraska-Lincoln;

-Siok A. Siek, Undergraduate Student, University of Nebraska-Lincoln; and

-Melissa Wilson, Assistant Professor, University of Minnesota

Acknowledgements

Funding for this project was provided by the North Central Region Sustainable Agriculture Research and Education program. Key partners in survey deployment were the American Agronomy Society Certified Crop Advisor Program, the Fertilizer Institute and Manure Manager magazine.

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2022. Title of presentation. Waste to Worth. Oregon, OH. April 18-22, 2022. URL of this page. Accessed on: today’s date.

Evaluation of geospatial data for livestock operation location and estimation of manure nutrient utilization capacity in five Nebraska counties

Purpose

Livestock and poultry manure are valuable sources of organic material and nutrients for crop production and pasture growth. Nonetheless, the trend away from diversified farms has disrupted the natural nutrient recycling of manure-fertilized cropping-systems. Meanwhile, inorganic fertilizer sales in Nebraska during 2020 reached a thirty-year high. This importation of nutrients, especially nitrogen and phosphorus fertilizer to areas rich in organic fertilizer products leaves an excess of nutrients that still must be utilized and leads to higher risk for nutrient contamination of surface and groundwater sources that would reduce quality of the water.

In areas where there is a high density of livestock production, utilization of manure nutrients may require additional cropland outside the livestock operations. Moreover, the transportation and application of manure has logistical challenges that remain critical to address to motivate the local recycling of organic nutrient amendments by crop producers and livestock owners.

The present research aims to bridge this gap of knowledge by developing a clearer understanding of nutrient utilization and supply capacities through exploration of county level geospatial data.

This analysis will have two main objectives:

-

- Quantify livestock inventories, associated manure production, inorganic fertilizer imports, and potential crop nutrient utilization, and calculate nutrient surpluses or deficits in five Nebraska counties.

- Identify and describe the suitable land for manure applications in each of the five target counties.

What Did We Do?

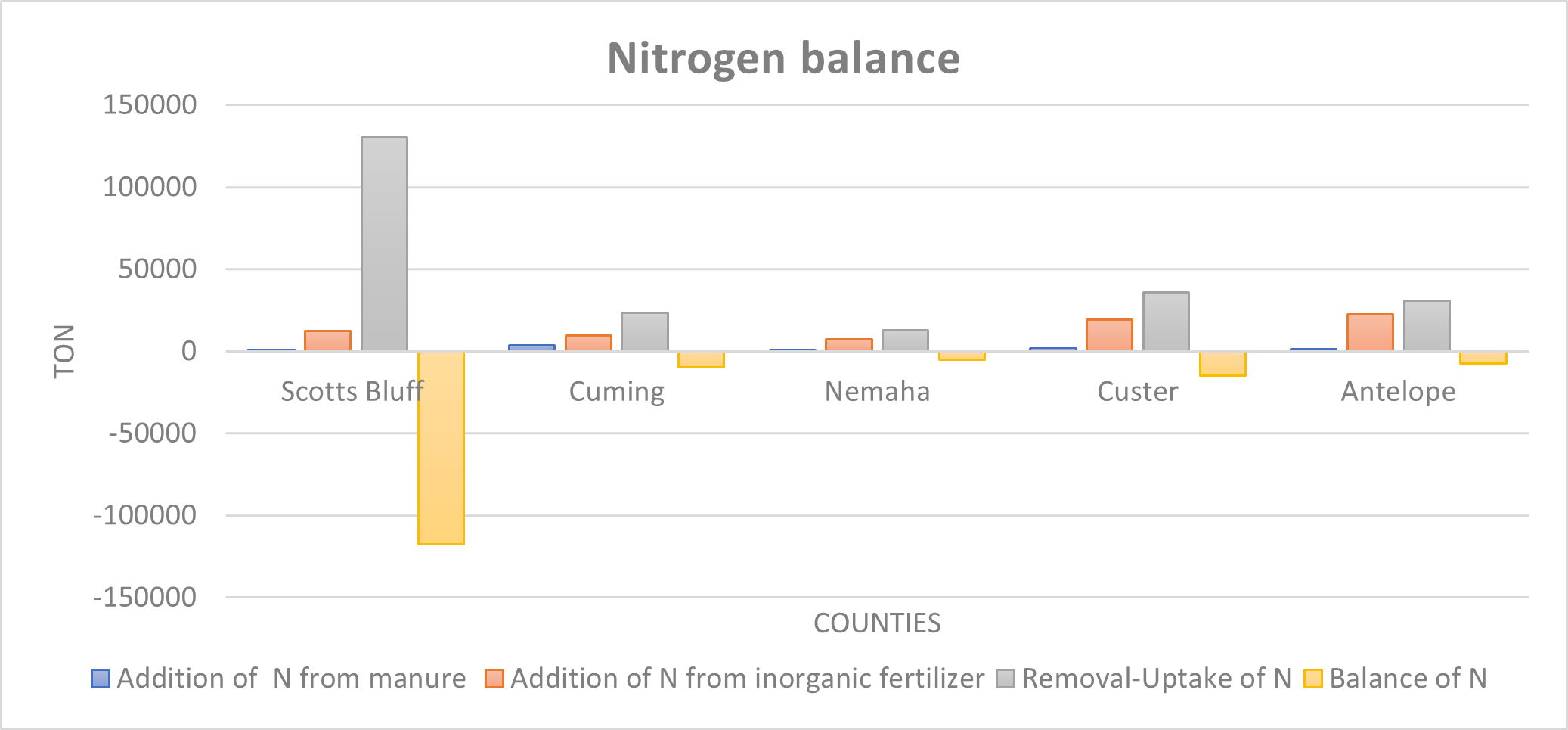

The research team selected five Nebraska counties (Scottsbluff, Cuming, Custer, Nemaha, and Antelope) for their agricultural importance and diverse geographical location and characteristics. The analysis of nutrients was realized using publicly available geospatial data and governmental databases.

Objective 1. Quantify livestock inventories, associated manure production, inorganic fertilizer imports, and potential crop nutrient utilization, and calculate nutrient surpluses or deficits in five Nebraska counties.

For this research, “livestock” includes poultry, pigs, and cattle (beef and dairy). The team used data from the USDA National Agricultural Statistics Service (NASS) (Table 1) to estimate the total animal units within each category based on NASS data for sales and end-year inventory.

The scope of this assessment was limited to include only commercial production livestock operations, which were operations with at least three animal units or with more than $2,000 in sales of livestock products. To obtain an annual average number of animal units at county-level two important assumptions, based on Kellog, Lander, Moffit, & Gollehon (2000) research: (1) different cycles of confinement for each animal category (according to its spans form birth to market) ; and (2) that sales throughout the year did not have seasonal variation. Algorithms for estimating animal units, average amount of recoverable manure, and its consequent rate for nitrogen and phosphorus levels were calculated using as reference the formulas and conversion factors adapted from Kellog, Lander, Moffit, & Gollehon (2000) and Gollehon, Kellog, & Moffitt (2016).

| Data/formula | Date | Source | |

| Hogs and pigs inventory and sales. | 2017 | USDA- NASS

|

|

| Cattle and Calves inventory and sales. | 2017 | USDA-NASS | |

| Poultry inventory and sales. | 2017 | USDA-NASS | |

| Estimated nutrients from commercial fertilizers. | 2016 | NUGIS- The Fertilizer Institute | |

| Crop production Layer | 2020 | USDA-NRCS-NASS | |

| Balance of nutrient | [Eq. 1]

|

Balance = Farm fertilizer nutrient used + Recoverable manure nutrient use – Nutrient in harvested crops

|

The balance of nutrients was thus determined using Eq 1 (Table 1); where farm fertilizer is estimated by fertilizer imports at county level (NuGis database, 2016). The nutrient in harvested crops is estimated with the yield report (USDA-NRCS-NASS), and average phosphorus and nitrogen uptake and fixation rate based on literature review [1].

Objective 2. Identify and describe the suitable land for manure application for each of the five target counties.

Six suitability factors were identified for manure application: land cover, potential for phosphorus uptake, proximity to road and streets, proximity to urban areas, slope, and proximity to water bodies (Table 2). Each factor class was weighted for their impact on manure application feasibility using the Analytic Hierarchy Process (AHP) and pairwise comparison method described by Doegan, Dodd, & McMaster (1994) where factors were given scores on nine objectives (A- Reducing surface water pollution, B-Reducing ground water pollution, C- Reducing soil contamination, D- Reducing runoff loss of nutrients, E- Reducing leaching loss of nutrients, F- Avoiding excessive use of manure, G-Increasing nutrient use efficiency, H-reducing cost of manure application, I- Reducing bad odor) through an objectives-oriented comparison (OOC) which values were adapted form Basnet, Apan, & Raine (2001) (Table 3).

|

Input Factors |

Data type |

Excluded land |

| Land cover | National Land Cover Database | Other land cover besides cropland |

| Potential uptake of cropland-P2O5 | Cropland Data Layer (CDL) | Grasslands, pastures, developed spaces, natural ecosystems. |

| Proximity to developed/urban areas | National Land Cover Database | Area less than 100 ft |

| Proximity to road and streets | TIGER Primary and secondary roads and streets | > 35 ft |

| Slope | DEM of Nebraska’s County | > 10% |

| Proximity to water bodies | National Hydrography Dataset | > 35 ft |

| Land cover | Criteria Weight |

| Potential uptake of cropland-P2O5 | 36 |

| Proximity to developed/urban areas | 6 |

| Proximity to road and streets | 6 |

| Slope | 20 |

| Land cover | 26 |

| Proximity to water bodies, rivers and streams | 6 |

| *Consistency ratio of weight distribution= 0.00 (This range is a measure if the reliability of the comparison and should be <0.1) |

[1] (Warncke, Dahl, & Zandstra, Nutrient Recommendations for Vegetable Crops in Michigan, 2004)(Kang, et al., 2020)(Meena, Kumar, Dhar, Paul, & Kumar, 2015)(Grains Research & Development Corporation, 2018)(Fertilizer Canada, 2001)(Grains Reseach & Development Research, 2018)Manitoba Government. (2009).(Barker, 2019) and ((Barker, 2017)(Warncke, Dahl, & Jacobs, 2009)(Sullivan, Peachey, Heinrich, & Brewer, 2020)(Grains Research & Development Corporation, 2018)(Sullivan, Peachey, Heinrich, & Brewer, 2020)International Plant Nutrition Institute (2013)).

What Have We Learned?

Objective 1.

The total balance of nutrients for each county showed that even though none of the counties we assessed have a surplus of nutrients at the county level, some of them are very close to meeting or surpassing the capacity of the land in the county to utilize additional nutrients. Of the five counties, Cumming county has the lowest phosphorus assimilation available at the county level, followed by Nemaha, Antelope, Custer, and Scotts Bluff. Balance nutrients showed a lower assimilation capacity on phosphorus than nitrogen. Since phosphorus is a nutrient limiting the growth of aquatic organisms and reduction on water quality, it was important to represent the potential phosphorus sinks at the geospatial level for Objective 2 (Figures 1 and 2).

Objective 2.

The area suitable for manure application in the five counties was mapped (Figure 3) with the Weighted Overlay Raster tool, on ArcGis Pro 2.9.1. This allowed the researchers to incorporate multicriteria effects with a weight for each factor. The results are summarized in Table 4 and present the proportion of land in each county that is either not suitable for manure application, has a marginal (medium) suitability, or is very suitable (high). These classifications were determined by natural breaks (Jenks) classification which partitioned data into classes based on natural groups in the data distribution.

We recognize that land suitable for manure application is closely associated with acres in crop production, which for Custer and Scottsbluff Counties is less than 50% of the total acres. Whereas Cuming County had the highest percentage of area dedicated to crop production, which explains the high proportion of “High suitability land”. The category of “Medium suitability” has the lowest percentage for all counties because it is mainly driven by differences in low and medium potential phosphorus uptake, based on crop type and area destinated for crop production, which are regularly more spatially scarce in vegetation patches.

Future Plans

-

- Validate the model of suitable land for manure application by checking the available data for manure production, cropland areas and slope with other official sources, and taking random samples among the counties to compare the results under field conditions.

- Incorporate a socio-economic analysis for manure transportation among and within different counties.

- While the county level context and characteristics have value, it would increase the accuracy of the model if more information about individual and smaller scale farms and animal feeding operations could be geospatially available. Thus, where possible, it is the researcher’s goal to improve the current analysis with the addition of more accurate data on animal operations within each county to adjust the estimation of manure production, and the nutrients balance.

- Promote Outreach efforts with farmers for making decisions based on a nutrient management approach that could decrease the importation of inorganic fertilizers, where possible.

Authors

Presenting author

María José Oviedo, Graduate Research Assistant, University of Nebraska-Lincoln

Corresponding author

A. Millmier Schmidt, Associate Professor & Livestock Manure Management Engineer, University of Nebraska-Lincoln

Corresponding author email address

aschmidt@unl.edu

Additional authors

A. Millmier Schmidt, Associate Professor & Livestock Manure Management Engineer, University of Nebraska-Lincoln; J. Iqbal, Assistant Professor, University of Nebraska-Lincoln; A. Yoder, Associate Professor, University of Nebraska Lincoln; and B. Maharjan, Assistant Professor, University of Nebraska Lincoln

Additional Information

Basnet, B. B., Apan, A. A., & Raine, S. R. (2001). Selecting Suitables Sites for Animal Waste Application Using Raster GIS. Environmental Management, 519-531.

Cassman, K., Dobermann, A., & Walters, D. (2002). Agroecosystems, Nitrogen-use Efficiency, and. Agronomy & orticulture– Faculty Publications, 356.

Fergunson, R. (2015). Groundwater Quality and NItrogen Use Efficiency in Nebraska’s Central Platte River Valley. Journal of Environmental Quality.

Gollehon, N., Caswell, M., Ribaudo, M., Kellog, R., Lander, C., & Letson, D. (2011). Confined Animal Production and Manure Nutrients. Washington, DC: Resource Economics Division, Economic Research Service, U.S. Department of.

Kellog, R. L., Lander, C. H., Moffit, D. C., & Gollehon, N. P. (2000, Diciembre). Manure Nutrients Relative to the Capacity of Cropland and Pastureland to Assimilate Nutrients. Retrieved from USDA: www.nhq.nrcs.usda.gov/land/index/publication.html

Nebraska Agriculture Department. (2021). Nebraska Agriculture Fact Card. Retrieved from https://nda.nebraska.gov/facts.pdf#:~:text=In%202020%2C%20Nebraska%20ranked%20second%20in%20ethanol%20production,operations%20were%20found%20on%2048%25%20of%20Nebraska%20farms.

Nebraska Department of Agriculture. (2020). Nebraska Fertilizer, Soil Conditioner and Ag Lime Tonnage and Sampling Reprot Calendar year 2020. Lincoln: nda.nebraska.gov.

Spiegal, S., Kleinman, P., Endale, D., Bryan, R., Dell, C., Goslee, S., . . . Gowda, e. a. (2020, June). Manuresheds: Advancing nutrient recycling in US agriculture. Agricultura Systems 182, 102813. doi:https://doi.org/10.1016/j.agsy.2020.102813

Doegan, H. A., Dodd, F. J., & McMaster, T. B. (1994). A Statistical Approach to Consistency in AHP. Marh.Comput.Modelling., 19-22.

Barker, B. (2017, April 4). Moderate flax response to nitrogen. Top Crop Manager. Retrieved from https://www.topcropmanager.com/moderate-flax-response-to-nitrogen-19985/#:~:text=Generally%2C%20flax%20takes%20up%202.83,sensitive%20to%20seed%2Dplaced%20fertilizer.

Barker, B. (2019, December 3). Managing phosphorus in flax. Top Crop Manager. Retrieved from https://www.topcropmanager.com/managing-phosphorus-in-flax/

Fertilizer Canada. (2001). Phosphorus Management for Pulses. Canola Council of Canada. Retrieved from https://www.canolacouncil.org/download/2042/canola-watch/14659/cfi_nutrient_uptake_for_wcanada_2001

Grains Reseach & Development Research. (2018). Grownotes: Chickpea-Section 5. Grains Reseach & Development Research. Retrieved from https://grdc.com.au/__data/assets/pdf_file/0030/369444/GrowNote-Chickpea-West-5-Nutrition.pdf

Grains Research & Development Corporation. (2018). Grownotes: Lentils- Section 7. Grains Research & Development Corporation. Retrieved from https://grdc.com.au/__data/assets/pdf_file/0028/366166/GrowNote-Lentil-West-7-Nutrition-Fertiliser.pdf

Grains Research & Development Corporation. (2018). Grownotes: Triticale-Section 5. Grains Research & Development Corporation. Retrieved from https://grdc.com.au/__data/assets/pdf_file/0025/370645/GrowNote-Triticale-South-05-Nutrition.pdf

Kang, F., Wang, Z., Xiong, H., Li, Y., Wang, Y., Fan, Z., . . . Zhang, Y. (2020). Estimation of Watermelon Nutrient Requirements based on the QUEFTS Model. Agronomy, 1776. Retrieved from file:///C:/Users/Majo/Downloads/agronomy-10-01776-v2.pdf

Manitoba Government. (2009). Calculating Manure Application Rates. Manitoba Provin. Retrieved from https://www.gov.mb.ca/agriculture/environment/nutrient-management/pubs/mmf_calcmanureapprates_factsheet.pdf

Meena, B. P., Kumar, A., Dhar, S., Paul, S., & Kumar, A. (2015). Productivity, nutrient uptake and quality of popcorn and potato in relation to organic nutrient management practices. ICAR-Indian Agricultural Research Institute, 110 012.

Sullivan, D. M., Peachey, E., Heinrich, A., & Brewer, L. J. (2020). Nutrient and Soil Health Management for Sweet Corn (Western Oregon). Oregon State University. Retrieved from https://catalog.extension.oregonstate.edu/sites/catalog/files/project/pdf/em9272.pdf

Warncke, D., Dahl, J., & Jacobs, L. (2009). Nutrient Recommendations for Field Crops in Michigan. Michigan State University. Retrieved from https://www.canr.msu.edu/fertrec/uploads/E-2904-MSU-Nutrient-recomdns-field-crops.pdf

Warncke, D., Dahl, J., & Zandstra, B. (2004). Nutrient Recommendations for Vegetable Crops in Michigan. Michigan State University.