Purpose

As a primarily mined material, the global reserve of phosphorus (P) is finite and running out. Consequently, inorganic, commercial fertilizers are becoming more expensive. Chemical engineering techniques have been developed and are being actively researched to recover P from wastewater sources in the form of struvite (MgNH4PO4 · 6H2O). Many wastewaters contain elements such as P and nitrogen (N) in various forms that could be recovered and beneficially recycled as fertilizer nutrients. Recovering nutrients, such as P, from wastewaters and/or treating wastewaters to the point they could be safely recycled back into the environment could have a tremendously positive impact on any agricultural activity as well as receiving waters.

Arkansas has a documented significant geographic nutrient imbalance, where the row-crop-dominated region of eastern Arkansas has a severe nutrient deficiency, particularly for P, which routinely requires commercial P applications to supply crop needs for optimum production. Thus, eastern Arkansas is an ideal setting for testing the effectiveness of recovered nutrients from wastewaters as fertilizer sources, especially P, for various row crops, namely rice, corn, and soybeans. A sustainable, wastewater-recovered source of P, in the form of the mineral struvite, would be a critical advancement in the long-term viability of P availability, P-source options, and use as a fertilizer in P-deficient soils used for crop production.

What Did We Do?

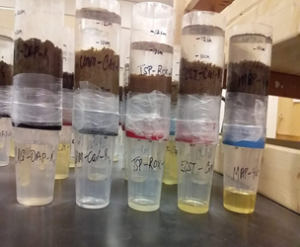

Various studies were conducted to evaluate the behavior of struvite in different soils and crop response to struvite as compared to other commonly used, commercially available fertilizer-P sources [i.e., monoammonium phosphate (MAP), diammonium phosphate (DAP), triple superphosphate (TSP), and rock phosphate (RP)]. Two struvite materials were tested, a chemically precipitated struvite (CPST) created from real wastewater treatment plant effluent and an electrochemically precipitated struvite (ECST) created in the laboratory with an innovative electrochemical approach.

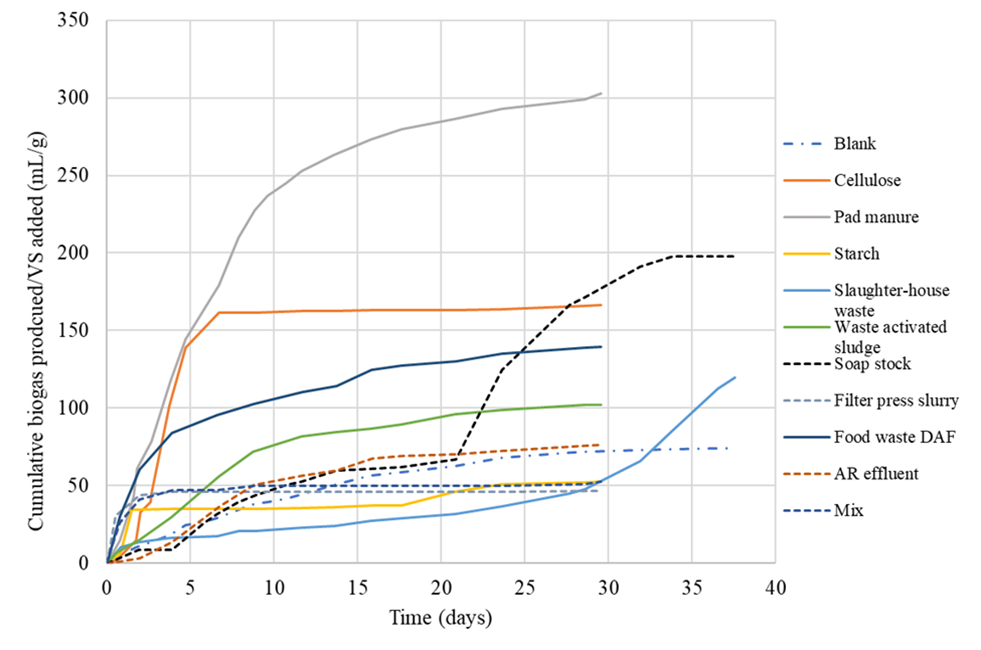

In the laboratory, a series of plant-less soil incubation experiments were conducted in several different agricultural soils to evaluate the behavior of struvite and the other fertilizer-P sources as they solubilize. Soil pH, water-soluble and plant-available P, magnesium (Mg), calcium (Ca), iron (Fe), nitrate and ammonium concentrations were measured over a 4- to 9-month period in moist/aerobic and saturated/flooded/anaerobic soil conditions (Figure 1). A column study was also conducted to evaluate the effects of fertilizer-P source, including ECST and CPST, on P-leaching characteristics over time in multiple soils (Figure 2).

Additionally, a rainfall-runoff simulation experiment was conducted to evaluate the effects of water source (i.e., rainfall, groundwater, and struvite-removed wastewater) and fertilizer-P source on runoff water quality parameters (i.e., pH, electrical conductivity, and P, N, Mg, Ca, and Fe concentrations) in various soils (Figure 3).

In the greenhouse, several potted-plant studies were conducted for 60-90 days evaluating above- and below-ground plant response to ECST, CPST, MAP, DAP, TSP, RP, and unamended controls in rice, corn, soybeans, and wheat. Studies were also conducted to evaluate the effects of fertilizer-P source (i.e., ECST, CPST, DAP, TSP, and an unamended control) on greenhouse gas emissions (i.e., CO2, CH4, and N2O) from flood- and simulated-furrow-irrigated rice (Figure 4).

In the field, two-year studies have been conducted in soil having low soil-test-P to evaluate the effects of fertilizer-P source (i.e., ECST, CPST, MAP, DAP, TSP, RP, and an unamended control) on above- and below-ground dry matter and tissue P, N, and Mg concentrations, aboveground tissue P, N, and Mg accumulations, and yields in rice, corn, and soybeans, as well as soil P concentrations in corn and soybeans (Figure 5).

What Have We Learned?

For the moist-soil incubations, averaged across fertilizer sources, differences in water-soluble soil P concentration [from their initial concentrations] differed among soils over time and, averaged across soils, among fertilizer sources over time. In addition, averaged across time, Mehlich-3-extractable soil P concentration differences from their initial concentrations differed among fertilizer sources within soils. For the flooded-soil incubations, averaged across fertilizer sources, the change in soil pH from the initial differed among soils over time. In addition, averaged across soils, the change in water-soluble soil P concentration from the initial differed among fertilizer sources over time. Results from the plant-less soil incubation experiments show that many elemental soil concentrations, namely P, and soil pH differed among soil-fertilizer-P-source combinations over time. However, in general, the two struvite materials (ECST and CPST) behaved similarly to one another and behaved similarly to at least one other commonly used, commercially available fertilizer-P source without any large, unexpected outcomes across several different agricultural soils with varying soil textures. Struvite appears to relatively similar soil behavior as other commercially available fertilizer-P sources.

For the greenhouse study, no differences were identified in soybean plant properties. However, corn plant properties and corn and soybean elemental tissue concentrations differed (P < 0.05) among fertilizer amendments. Total corn dry matter from ECST did not differ from that from RP and TSP and was 1.2 times greater than that from CPST Belowground corn dry matter from ECST was 1.9 times greater than that from CPST, TSP, DAP, and the unamended control treatments Corn cob-plus-husk dry matter from CPST and ECST were similar. Corn belowground tissue P concentration from CPST did not differ from that from DAP, TSP, and MAP and was 1.4 times larger than that from ECST. Corn cob-plus-husk tissue P concentration from ECST was similar to that from MAP and DAP and was 1.2 times larger than that from CG. Corn stem-plus-leaves tissue P concentration from ECST differed from that from all other treatments and was 1.8 times greater than that from the unamended control. Struvite appears to be a viable, alternative fertilizer-P source.

For the 2019 rice field study, neither above- or belowground P, Mg, and N tissue concentrations differed among fertilizer sources. For the 2019 corn field study, neither above- or below-ground P, Mg, and N tissue concentrations differed among fertilizer sources. For the 2019 soybean field study, neither aboveground Mg or N nor belowground P, Mg, and N tissue concentrations differed among fertilizer sources. However, aboveground tissue P concentration was greater from ECST than from RP and the unamended control. For the 2020 rice field study, aboveground dry matter and aboveground dry matter P, N, Mg concentrations did not differ among fertilizer sources. However, rice grain yield from ECST was similar to that from CPST, but both were lower than from TSP. Aboveground Mg uptake from ECST was greater than that from CPST. For the 2020 corn field study, total aboveground, cob/husk, and stalk/leaves dry matter, aboveground P, N, and Mg concentrations and uptake, and belowground P and N concentrations did not differ among fertilizer sources. However, corn yield was larger from ECST than from all other fertilizer treatments, which did not differ among themselves. Belowground Mg concentration was numerically largest from ECST among all fertilizer-P treatments and was significantly greater than that from MAP, DAP, and TSP. For the 2020 soybean field study, neither aboveground dry matter nor yield differed among fertilizer sources. Similar to greenhouse results, struvite appears to be a viable, alternative fertilizer-P source for multiple agronomic crops, including rice, corn, and soybean.

Results from a greenhouse trial in 2021 showed that, across 13 sample dates over a nearly 4-month period evaluating the effects of fertilizer-P source on greenhouse gas fluxes and emissions from flood-irrigated rice, CO2 fluxes were unaffected by fertilizer-P source, but differed over time, while both CH4 and N2O fluxes differed among fertilizer-P treatments over time. Furthermore, results showed generally lower CO2, CH4, and N2O fluxes from ECST than from the other fertilizer-P sources and numerically lower CO2 and N2O season-long emissions from ECST than from the other fertilizer-P sources, while CH4 emissions from ECST were numerically lower than from CPST in flood-irrigated rice. Electrochemically precipitated struvite may have potential to reduce greenhouse gas emissions from flood-irrigated rice.

Future Plans

Future plans include additional laboratory rainfall-runoff simulation experiments, greenhouse potted-plant trials, and field studies to evaluate the effects of real-wastewater-derived struvite compared to other commonly used, commercially available fertilizer-P sources on soil and plant response as well as greenhouse gas emissions.

Authors

Presenting author

Lauren F. Greenlee, Associate Professor, Pennsylvania State University

Corresponding author

Kristofor R. Brye, University Professor, University of Arkansas

Corresponding author email address

kbrye@uark.edu

Additional authors

Lauren F. Greenlee, Associate Professor, Pennsylvania State University

Niyi Omidire, Post-doctoral Research Associate, University of Arkansas

Tatum Simms, Graduate Research Assistant, University of Arkansas

Diego Della Lunga, Graduate Research Assistant, University of Arkansas

Ryder Anderson, former Graduate Research Assistant, University of Arkansas

Shane Ylagan, Graduate Research Assistant, University of Arkansas

Machaela Morrison, Graduate Research Assistant, University of Arkansas

Chandler Arel, Graduate Research Assistant, University of Arkansas

Additional Information

Anderson, R., K.R. Brye, L. Greenlee, and E. Gbur. 2020. Chemically precipitated struvite dissolution dynamics over time in various soil textures. Agricultural Sciences 11:567-591.

Ylagan, S.R., K.R. Brye, and L. Greenlee. 2020. Corn and soybean response to wastewater-recovered and other common phosphorus fertilizers. Agrosystems, Geosciences & Environment 3:e20086.

Anderson, R., K.R. Brye, L. Greenlee, T.L. Roberts, and E. Gbur. 2021. Wastewater-recovered struvite effects on total extractable phosphorus compared with other phosphorus sources. Agrosystems, Geosciences & Environment 4:e20154.

Anderson, R., K.R. Brye, L. Kekedy-Nagy, L. Greenlee, E. Gbur, and T.L. Roberts. 2021. Total extractable phosphorus in flooded soil as affected by struvite and other fertilizer-P sources. Soil Science Society of America Journal 85:1157–1173.

Anderson, R., K.R. Brye, L. Kekedy-Nagy, L. Greenlee, E. Gbur, and T.L. Roberts. 2021. Electrochemically precipitated struvite effects on extractable nutrients compared to other fertilizer-P sources. Agrosystems, Geosciences & Environment 4:e20183.

Omidire, N.S., K.R. Brye, T.L. Roberts, L. Kekedy-Nagy, L. Greenlee, E.E. Gbur, and L.A. Mozzoni. 2021. Evaluation of electrochemically precipitated struvite as a fertilizer-phosphorus source in flood-irrigated rice. Agronomy Journal 114:739–755. DOI: 10.1002/agj2.20917

Brye, K.R., and L.F. Greenlee. 2022. What is struvite and how is it used? Blog post for Soil Science Society of America’s “Soils Matter” blog (https://soilsmatter.wordpress.com/).

Acknowledgements

The authors acknowledge funding from the USDA NIFA AFRI Water for Food Production Systems program, grant #2018-68011-28691 and funding from the National Science Foundation, grant #1739473.

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2022. Title of presentation. Waste to Worth. Oregon, OH. April 18-22, 2022. URL of this page. Accessed on: today’s date.