Purpose

This project was conducted to increase our knowledge of the implications of using low-quality carbon feedstocks as the carbon layer within a Shallow Burial with Carbon (SBC) system. This system is also known as theTrench Composting and Above Ground Burial. SBC requires a 1-foot layer of carbon material in the bottom of the trench. This carbon material serves three purposes: 1) absorbs and temporarily traps leachate released from the decomposing carcasses, 2) provides elemental carbon to the microorganisms that the system fosters to decompose carcasses, and 3) temporarily traps oxygen in the system. To date, most applications of the SBC system have utilized wood products such as shavings, wood chips, and mulch. These products are generally effective at all 3 functions. While these carbon materials are successful feedstock for SBC, wood products are not widely available in parts of the country.

Regions with few woody carbon sources often have ready access to crop residues such as corn stover, rice hulls, straw, or hay. These carbon feedstocks generally have a significantly lower carbon-to-nitrogen ratio than woody carbon sources. For example, wood shavings typically have a C:N ratio of around 550:1 while the C:N ratio of straw is 100:1 or less. Materials with a higher C:N ratio may have more elemental carbon available for the metabolic activities of the microorganisms. Crop residues tend to have a waxy cuticle layer that decreases their capacity to absorb leachate compared to woody materials. Finally, crop residues tend to compress under the weight of the carcasses and the SBC system’s soil cover. This compression decreases the amount of oxygen trapped in the pore spaces between particles. The degree to which these differences in the physical and chemical properties of woody products compared to crop residues impact their effectiveness as a carbon source in an SBC system has been unknown.

What Did We Do?

The study was conducted at the Horticulture Crops Research Station in North Carolina (Address: 2450 Faison Hwy, Clinton, NC 28328). This station is affiliated with NC Department of Agriculture and Consumer Services (NCDA&CS) and North Carolina State University (NCSU) is in the coastal plains region of North Carolina. The project site contained a weather station belonging to the state climate office (ECONET Station ID: CLIN) with continuous monitoring of primary weather variables such as air temperature, precipitation, wind speed, in addition to soil temperature, soil moisture content, and evapotranspiration.

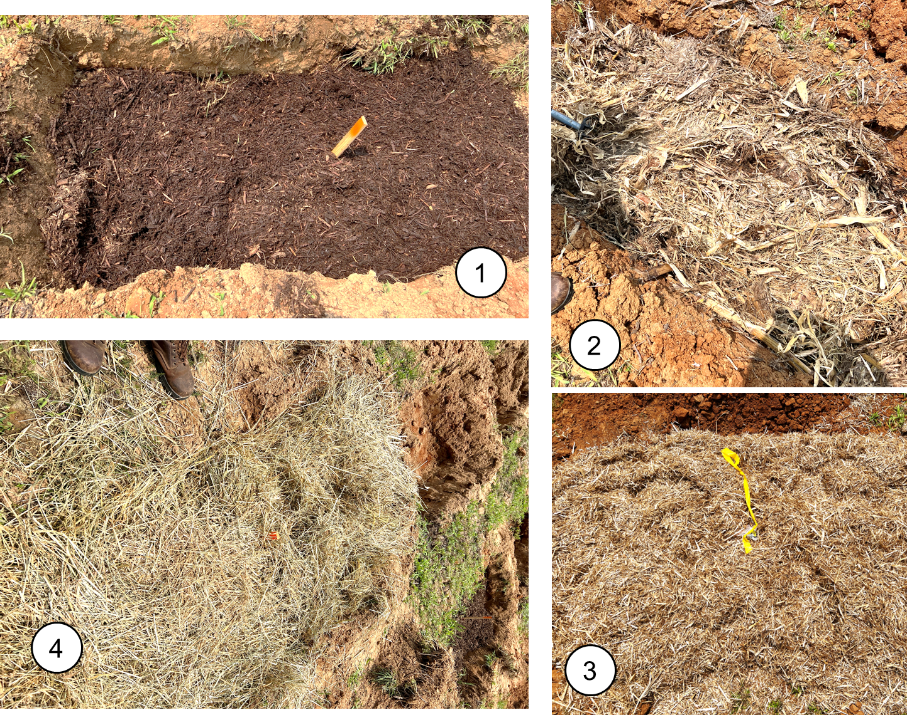

Individual trenches were excavated for each treatment, ensuring each treatment combination (carbon material and carcass condition) was isolated to prevent cross-contamination. The placement of treatments was randomized to minimize bias and allow for a more rigorous comparison of outcomes. A total of 72 pigs of similar size were used, divided between whole and ground carcass treatments. Figure 1 below illustrates the site preparation.

Carcass decomposition was assessed using a five-point scale developed by Brown (2007), as adapted by Lochner et al. (2022) (Table 1). Observers scoring the decomposition were all trained and experienced carcass management subject matter experts, ensuring consistent and reliable assessments of carcass breakdown across all treatments.

| Score | Criteria |

|---|---|

| 1 | Large amounts of flesh, hide and hair present. Internal fluid is still visible. Carcass is still discernible. |

| 2 | Flesh, hide and hair are present in smaller amounts. Carcass is no longer discernible. No internal fluid visible. |

| 3 | Slight amounts of hair and hide present. Numerous large and small bones are present. |

| 4 | No hide present. Minimal hair visible. Flesh completely degraded and only large bones were present. |

| 5 | No flesh, hide, or hair present. Few to no large brittle bones present. |

What Have We Learned?

Precipitation was analyzed in relation to evapotranspiration on a day-by-day basis. This was conducted by running a daily tally of precipitation less evapotranspiration for the entire study period; a positive value indicated a net water surplus (accumulation) while a negative value suggested deficit (or drying). Throughout the study period, the volumetric water content (VWC) fell between 25% and 35% which is close to the field capacity (FC) value for the site soil types. Collectively, these observations indicate the site soils experienced near-saturation conditions during the study period. Observers during each excavation activity reported noticeable soil wetness in the burial areas; but no pooled water.

Over the burial period, whole carcass decomposition was shown to gradually transition from a relatively low to higher decomposition score. Since these scores are ordinal but not continuous variables, we opted to avoid averaging them avoiding confusion in interpretation.

The data indicates that all four carbon sources in this study (hardwood mulch, wheat straw, corn fodder, and fescue hay) provided an acceptable level of decomposition of whole swine carcasses after twelve months. This trial used finishing hogs. If larger breeding stock had been used the results may have been different.

Future Plans

Data analysis is ongoing to assess statistical significance in decomposition extent and ranking by observers. Also, downward movement associated with different treatments (different carbons, whole vs ground carcass) is currently being analyzed. Results provide guidance for site selection, carbon source screening, and relevant protective measures for water quality at the site. Future evaluation of the shallow burial with carbon (SBC) technology are planned in other sites/regions with results to be compared to this evaluation.

Authors

Presenting & corresponding author

Mahmoud Sharara, Associate Professor and Extension Specialist, Biological and Agricultural Engineering Department, North Carolina State University, Raleigh, North Carolina, msharar@ncsu.edu

Additional authors

Gary Flory, G.A. Flory Consulting LLC President, Director of Operations

Bobby Clark, Senior Extension Agent, Shenandoah County Office

Bob Peer, Agricultural Program Coordinator, Virginia Department of Environmental Quality

Mark Hutchinson, Professor Emeritus of Sustainable Agriculture, University of Maine Cooperative Extension

Acknowledgements

The authors would like to acknowledge Smithfield Foods for providing deadstock used in conducting this study. The authors also would like to acknowledge Hunter Barrier, Superintendent for the Horticultural Crops Research Station in Clinton, NC for providing space and resources needed for this work. The authors also would like to acknowledge Research Station crew for their timely support during project activities.

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2025. Title of presentation. Waste to Worth. Boise, ID. April 7-11, 2025. URL of this page. Accessed on: today’s date.