Due to a technical glitch, the beginning of the recorded presentation was not recorded. Please accept our apologies.

Purpose

To address the depletion of phosphorus resources and the environmental issues associated with phosphorus enriched runoff from the application of raw manure, a strategic and sustainable approach is to recycle phosphorus from dairy manure using innovative and efficient methods. Hydrothermal carbonization (HTC) has been considered one of the sustainable techniques, which can transform dairy manure into phosphorus-enriched hydrochar at relatively low temperatures, typically ranging from 180 to 250 °C. This process not only recovers valuable phosphorus but also converts organic waste into a stable, nutrient-rich product that can be used as a soil amendment or phosphorus fertilizer.

Despite the massive experimental activity performed to characterize the HTC process, the design and development of a validated bench-scale model is crucial for scaling up. While numerous studies have explored the HTC process at the laboratory level, only a limited number of studies have assessed the technical feasibility and performance of implementing this process on an industrial scale. In this context, the purpose of this study was to provide a detailed and systematic examination of phosphorus recovery from dairy manure using a lab-scale HTC reactor and illustrated the basis of the design of a bench-scale processor and evaluated its performance in terms of hydrochar yield (HY) and phosphorus recovery (PR).

What Did We Do?

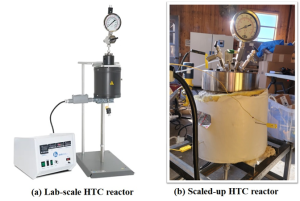

In this study, the HTC of raw dairy manure with a 7.9% of total solids was first conducted using the lab-scale reactor to optimize the process parameters, including temperature and reaction time, and then scaled up at a scale of 30 times larger (Fig. 1). The HTC-derived hydrochar samples were named according to the temperature and reaction time. For example, HC200-30 represents the hydrochar sample obtained at 200 °C and 30 min. The scaled-up reactor was designed and operated at the optimized conditions obtained from the lab-scale study, which was 225 ºC and 60 min of reaction time. The HY, which also reflects the mass reduction of dairy manure (on a dry weight basis), and PR were the two main parameters evaluating the HTC of dairy manure. We additionally evaluated the energy required for hydrochar processing in both lab- and bench-scale processors.

The HY and PR expressed as a percentage were determined by the following equations:

What Have We Learned?

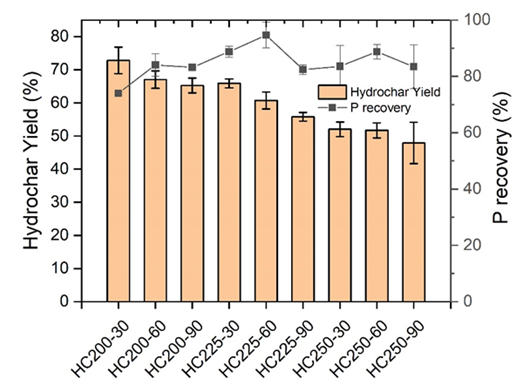

Fig. 2 shows the effects of HTC processing temperature and reaction time on the HY and PR using the lab-scale reactor. It was observed that the HY decreased gradually as the processing temperature and time increased, which is attributed to the temperature and time dependent degradation of organic matter during HTC. The highest PR was observed at 225 ºC and 60 min.

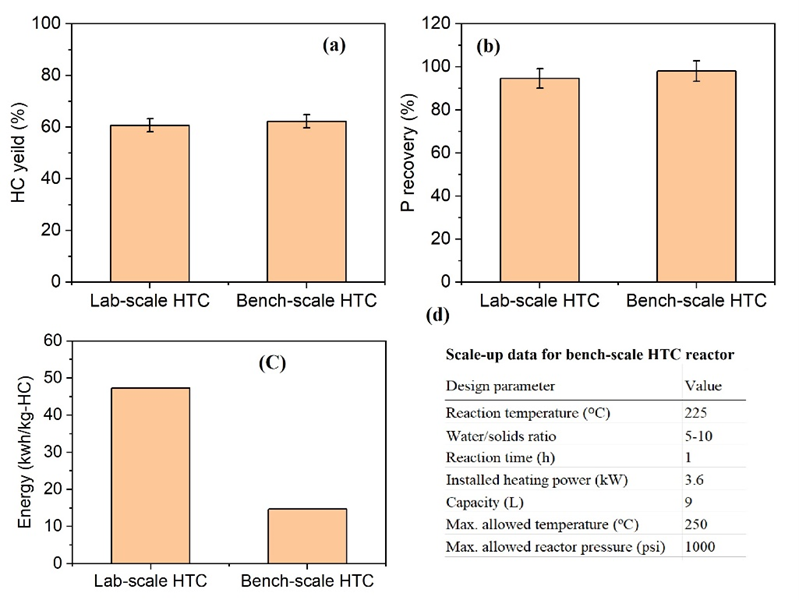

As shown in Fig. 3, the scale-up of the hydrothermal carbonization (HTC) process demonstrated that HY and PR remained consistent between lab-scale and bench-scale systems, indicating that the transition to a larger reactor did not compromise HY or PR. Notably, the energy input per mass of hydrochar was significantly reduced in the bench-scale system, improving overall energy efficiency. These findings indicate that scaling up HTC can enhance process feasibility while maintaining similar nutrient recovery.

Future Plans

We plan to further develop a continuous-flow HTC system at pilot-scale as a potential advanced manure processing pathway. We will also conduct technoeconomic and environmental assessments to verify scalability and sustainability.

Authors

Presenting author

Mohammad Nazrul Islam, Postdoctoral Fellow, University of Idaho

Corresponding author

Lide Chen, Professor, Dept. of Soil & Water Systems, University of Idaho, lchen@uidaho.edu

Additional author

Brian He, Professor, Dept. of Chemical and Biological Engineering, University of Idaho

Acknowledgements

This work is supported partially by USDA NIFA (award number 2021-67022-35504) and the University of Idaho P3R1 grant.

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2025. Title of presentation. Waste to Worth. Boise, ID. April 7-11, 2025. URL of this page. Accessed on: today’s date.