This webinar will explore how mortality is part of livestock production, whether in the day-to-day on the farm or after a catastrophic disease or environmental disaster. Handling and disposal of mortality in a safe and efficient manner is critical for continuity of operations. In this webinar, the presenters will present on studies evaluating different techniques of mortality management and the lessons learned from each study This presentation was originally broadcast on October 10, 2025. Continue reading “Mortality Management – From Routine to Catastrophic”

Concise Composting

Purpose

Timber Creek Recycling has operated a turned windrow composting operation using manure and food waste processing by-products and green waste for over a decade in Meridian, Idaho. Pressure from suburban encroachment and the availability of increasingly difficult feedstocks that had excessive odor, created the need to move operations from a farm to an industrial site. Land costs were greater, and potential odor impacts would increase in this move. The owner also requested that the number of touches be reduced to minimize the current workload for compost operators. There are some essential operational & design considerations to manage manure composting on a concise footprint and a limited budget. This presentation describes the operation and design considerations that can apply to any composting operation.

What Did We Do?

Green Mountain Technologies considered three different models of concise composting. Radial stacker bunkers, using a central pivot telescopic conveyor to place and cover active compost piles. Also inwardly turned circular aerated piles, which use a side discharge compost turner to turn the compost towards the center of a large circle. Timber Creek Recycling decided to use a narrow profile rectangular shaped turned aerated pile composting approach. This form uses a long concrete aeration floor that allows the owner to build capacity in six phases and increase the operating efficiencies with each additional phase. This approach kept the expansions in line, so that delivery trucks could unload directly in front of the piles and so that side discharge compost turners could be used to mix feedstocks into one side of the pile and move the composting material through different aeration floor capacities and finally to a long collection belt that directly fed a compost screener. This and the aeration floor reduced touches from 12 to 9, compared to non-aerated windrows, and provided a once a week turning frequency, reducing compost, and curing time from 90 to 45 days.

Steps taken to reach this point.

Industrial land was purchased in Nampa, Idaho, permits received and phase one of construction has been completed and operated for over 9 months. The design compacted a 30-acre operational site to a 12-acre operational site with significantly more capacity than the original. Odor reduction steps were taken to reduce the odor of cheese whey waste activated sludge being delivered to the site by using a lime additive during the screw press step at the cheese manufacturer. A small straddle windrow turner was used to mix the delivered feedstocks, and a food waste de-packager was installed to manage out-of-date or off-specification foods.

What Have We Learned?

The use of reversing direction aeration was not necessary when using positive aeration using a cap of wet wood chips or screened compost covers on top of the piles for the first 7 to 10 days. Odors have not been a problem at the new site using forced aeration compared with turned windrows (un-aerated) at the old site. The higher horsepower side discharge conveyor compost turners do not make economic sense just for phase one but will for all three phases. Wastewater collection and reuse is difficult to manage and needs to be incorporated into the mixing and turning process using an underground main and hose reel located at the far end of the aeration pads.

Take home messages

Aeration using blowers and airpipes below a concrete floor can effectively keep composting operations with challenging feedstocks from smelling bad and increase the biological efficiency and throughput. Use of a woody moist bio cover over the top of the pile is essential for the first 7-10 days for these feedstocks.

Force air through a compost pile at least 6 times per hour using on/off timers to control pile temperatures between 125° and 145° F and to keep oxygen above 13% using a rate of 3-5 CFM/cubic yard. Automated temperature feedback controllers make this simpler and more dependable.

Turn and re-water at least 2 times in the first month, either by top irrigation within 30 minutes before turning, or using a hose reel and spray bar connected to the turner (better) or simply turn piles at least 30 minutes after a big rain event.

Piles shrink over time- Double up the piles after 2 weeks and cure with less forced air at 1-2 CFM/cubic yard for an additional 2 weeks.

Adding capacity over time without increasing travel distances requires delivery directly to the initial composting area and collection from the distant piles using conveyors. On-farm generated feedstocks and the composting operations should be placed together as close as possible. Have delivery and storage of outside amendments be alongside your manure or processing waste discharge locations.

Each touch of the material should be limited, and with each touch involving several key feedstock preparation actions while entering a composting system, such as metering materials together in the correct proportions, and mixing thoroughly while watering and delivering into the first composting stage. Examples include building windrows proportionally with loaders and turning and watering with a windrow turner that can apply pond wastewater as it turns. Second example, if a conveyor is used to collect and discharge a manure in a CAFO, add bulking materials prior to the last conveyor and place into an in-line pug mill before stockpiling or placement on an aeration floor. The third example when using side dump delivery trucks, have trucks unload manure in a long low windrow, and then place the amendment in another long low windrow alongside about 22 feet apart, then use a side discharge windrow turner with a spray bar to apply wastewater to combine and then mix the windrows together using the turner in 2 passes. Large loaders move about 500 cubic yards per hour, compost turners move over 4000 cubic yards per hour. So each touch is cheaper per unit.

Future Plans

Phases two and three are under development to move the entire windrow operation from Meridian Idaho to the new site within 2 years.

Authors

Presenting authors

-

- Jeffrey Gage, Director of Consulting, Green Mountain Technologies, Inc.

- Mike Murgoitio, President, Timber Creek Recycling

- Caleb Lakey, Vice President, Timber Creek Recycling, LLC

Corresponding author

Jeffrey Gage, Director of Consulting, Green Mountain Technologies, Inc., jeff@compostingtechnology.com

Additional author

Caleb Lakey, Vice President, Timber Creek Recycling, LLC.

Additional Information

-

- https://www.compostingtechnology.com

- https://www.timbercreekrecycling.com/

- Citations

- Industrial Composting: Environmental Engineering and Facilities Management, Eliot Epstein, CRC Press, 2011. https://www.taylorfrancis.com/books/mono/10.1201/b10726/industrial-composting-eliot-epstein?_ga=2.37894116.67590306.1739841108-1296093157.1739841108

- Compost Science & Utilization https://www.tandfonline.com/journals/ucsu20

- Biocycle Magazine https://www.biocycle.net/

- Case Studies: Annen Brothers, Mt Angel, OR. Timber Creek Recycling, Meridian and Nampa, ID. Stage Gulch Organics Compost Facility, Sonoma, CA.

Pilot-scale Composting System to Measure Air Emissions from Dairy Manure and other Byproducts

Purpose

The overall objectives of this research are to investigate the design, implementation, and evaluation of a pilot-scale composting system for dairy manure. This composting system was developed because of the significant quantities of dairy manure produced in Idaho and the need to improve dairy compost quality while reducing air emissions during the composting process. This composting system provides the ability to simulate on-farm composting in Idaho while measuring and regulating key composting parameters, gas emissions, and implementing changes during operation.

What Did We Do?

This pilot-scale composting system was developed by adapting a home composter to simulate a mechanically turned windrow system. The composters were modified to include aeration control, air monitoring equipment (Gasmet), and measure key composting parameters throughout the process. Ten compost reactors were built, which allowed for several combinations of treatments and multiple replications. Each reactor is connected to a plenum with the capacity to interconnect several reactors or isolate each one and regulate airflows and chamber pressure. During the initial trial, two replications of each amendment: control, biochar, pumice, wood chips, and zeolites were evaluated. A follow-up trial will repeat the two replications per treatment, for a total of four replications. Modifications of the composting system during the trial addressed challenges with moisture control, odor, temperature regulation, air velocity, and compost balling.

Figures 1 and 2 define the blocking pattern and layout of the composting system for all ten compost reactors. The blocking pattern was generated for two primary reasons: Create replications for each treatment and compensate for a temperature differential between both ends of the research space caused by the cooling method in the greenhouse.

What Have We Learned?

We learned that the pilot-scale composting system can effectively simulate different types of on-farm composting methods, demonstrating its adaptability for research. During the composting trial, the aeration was regulated to simulate forced and natural airflow composting systems. The ability to continuously measure the headspace size confirmed a significant decrease in composting volume, as expected in a full sized composting system. The temperature monitoring showed we were able to reach thermophilic composting for the first two weeks of the trial and showed temperature increases at each turning event. These findings indicate that this system can be a valuable tool for developing more efficient on-farm dairy manure management practices at the pilot-scale.

Future Plans

The design and implementation of this composting system have only completed one trial run. The immediate next step is to complete another round of the compost trial. Each resulting compost mix with the corresponding amendment will be tested in a crop-testing greenhouse trial. The amount of compost, or any other products, handled by these reactors allows for further tests in the lab, at the pilot scale, or in a greenhouse.

In the short term and beyond the dairy manure trials, the reactor system will be tested for other processes, including different composting techniques and amendments. Other processes to be tested include soil amendments and their impact on air emissions, anaerobic digestion without mixing, emissions from diverse waste streams and amendment combinations, among others.

Authors

Presenting author

Anthony Scott Simerlink, Assistant Professor, Extension Educator – Power County, University of Idaho

Corresponding author

Mario E. de Haro-Martí, Professor, Extension Educator – Gooding County, University of Idaho, mdeharo@uidaho.edu

Acknowledgements

Funding for this project was provided by a USDA-NIFA Sustainable Agriculture Systems (SAS) grant #2020-69012-31871.

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2025. Title of presentation. Waste to Worth. Boise, ID. April 7–11, 2025. URL of this page. Accessed on: today’s date.

Emissions from Composting

This webinar focuses on air emissions associated different methods of composting and the subsequent emissions when composted manure is applied to cropland. This presentation was originally broadcast on September 18, 2020. More… Continue reading “Emissions from Composting”

Manure Management Technology Selection Guidance

Proceedings Home | W2W Home

Purpose

Manure is an inevitable by-product of livestock production. Traditionally, manure has been land applied for the nutrient value in crop production and improved soil quality.With livestock operations getting larger and, in many cases, concentrating in certain areas of the country, it is becoming more difficult to balance manure applications to plant uptake needs. In many places, this imbalance has led to over-application of nutrients with increased potential for surface water, ground water and air quality impairments. No two livestock operations are identical and manure management technologies are generally quite expensive, so it is important to choose the right technology for a specific livestock operation. Information is provided to assist planners and landowners in selecting the right technology to appropriately address the associated manure management concerns.

What did we do?

As with developing a good conservation plan, knowledge of manure management technologies can help landowners and operators best address resource concerns related to animal manure management. There are so many things to consider when looking at selecting various manure treatment technologies to make sure that it will function properly within an operation. From a technology standpoint, users must understand the different applications related to physical, chemical, and biological unit processes which can greatly assist an operator in choosing the most appropriate technology. By having a good understanding of the advantages and disadvantages of these technologies, better decisions can be made to address the manure-related resource concerns and help landowners:

• Install conservation practices to address and avoid soil erosion, water and air quality issues.

• In the use of innovative technologies that will reduce excess manure volume and nutrients and provide value-added products.

• In the use of cover crops and rotational cropping systems to uptake nutrients at a rate more closely related to those from applied animal manures.

• In the use of local manure to provide nutrients for locally grown crops and, when possible, discourage the importation of externally produced feed products.

• When excess manure can no longer be applied to local land, to select options that make feasible the transport of manure nutrients to regions where nutrients are needed.

• Better understand the benefits and limitations of the various manure management technologies.

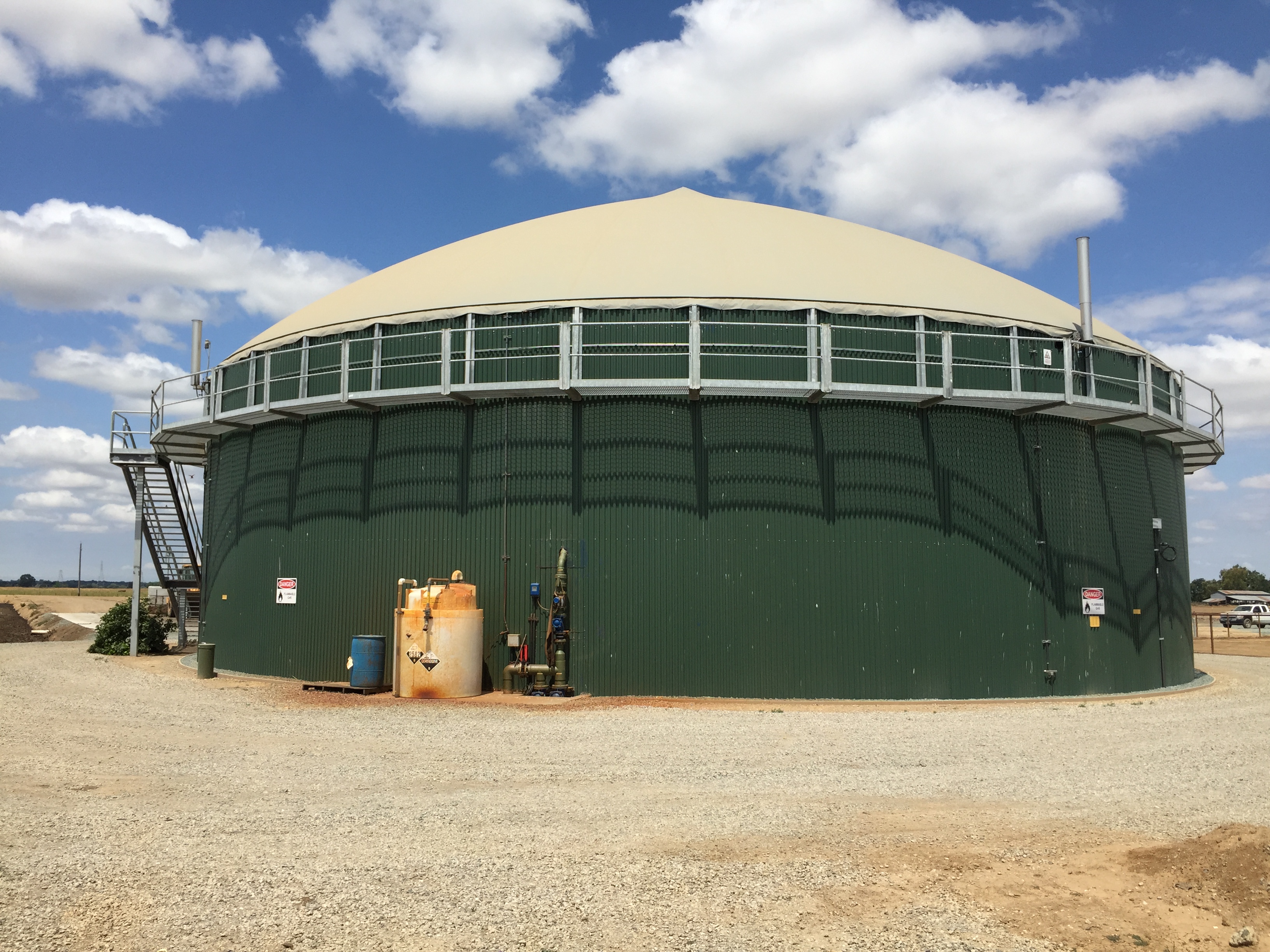

Complete-Mix Anaerobic Digester – option to reduce odors and pathogens; potential energy production

Gasification (pyrolysis) system – for reduced odors; pathogen destruction; volume reduction; potential energy production.

Windrow composting – reduce pathogens; volume reduction

Centrifuge separation system – multiple material streams; potential nutrient

partitioning.

What have we learned?

• There are several options for addressing manure distribution and application management issues. There is no silver bullet.

• Each livestock operation will need to be evaluated separately, because there is no single alternative which will address all manure management issues and concerns.

• Option selections are dependent on a number of factors such as: landowner objectives, manure consistency, land availability, nutrient loads, and available markets.

• Several alternatives may need to be combined to meet the desired outcome.

• Soil erosion, water and air quality concerns also need to be addressed when dealing with manure management issues.

• Most options require significant financial investment.

Future Plans

Work with technology providers and others to further evaluate technologies and update information as necessary. Incorporate findings into NRCS handbooks and fact sheets for use by staff and landowners in selecting the best technology for particular livestock operations.

Corresponding author, title, and affiliation

Jeffrey P. Porter, P.E.; National Animal Manure and Nutrient Management Team Leader USDA-Natural Resources Conservation Service

Corresponding author email

Other authors

Darren Hickman, P.E., National Geospatial Center of Excellence Director USDA-Natural Resources Conservation Service; John Davis, National Nutrient Management Specialist USDA-Natural Resources Conservation Service, retired

Additional information

References

USDA-NRCS Handbooks – Title 210, Part 651 – Agricultural Waste Management Field Handbook

USDA-NRCS Handbooks – Title 210, Part 637 – Environmental Engineering, Chapter 4 – Solid-liquid Separation Alternatives for Manure Handling and Treatment (soon to be published)

Webinars

Evaluation of Manure Management Systems – http://www.conservationwebinars.net/webinars/evaluation-of-manure-management-systems/?searchterm=animal waste

Use of Solid-Liquid Separation Alternatives for Manure Handling and Treatment – http://www.conservationwebinars.net/webinars/use-of-solid-liquid-separation-alternatives-for-manure-handling-and-treatment/?searchterm=animal waste

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2017. Title of presentation. Waste to Worth: Spreading Science and Solutions. Cary, NC. April 18-21, 2017. URL of this page. Accessed on: today’s date.

Recommendations of the Chesapeake Bay Program Expert Panel on Manure Treatment Technologies

Proceedings Home | W2W Home

Purpose

The US EPA Chesapeake Bay Program assesses nutrient loading to the Chesapeake Bay. There is a need to determine the impact of manure treatment technologies on reducing the nitrogen and phosphorus loading from agriculture. Furthermore, many states within the Chesapeake Bay Watershed control nutrient discharges through watershed nutrient trading programs. Tables of standard nutrient removal efficiencies of various technologies will allow states to implement these programs.

What did we do?

An expert panel was convened by the EPA Chesapeake Bay Program to determine nutrient removal potential of manure treatment technologies. The following seven technology categories were reviewed: thermochemical processing, anaerobic digestion, composting, settling, mechanical solid-liquid separation, and wet chemical treatment. Within these categories, the panel defined 24 named technologies for detailed review. The scientific literature was reviewed to determine the ability of each technology to transfer volatile nitrogen to the atmosphere and transfer nutrients to a waste stream more likely to be used off-farm (or transported out of the Chesapeake Bay Watershed).

What have we learned?

Manure treatment technologies are used reduce to odors, solids, and organic matter from the manure stream, with only minor reductions in nutrient loading. The panel determined that Thermo-Chemical Processing and Composting have the potential to volatilize nitrogen, and all of the technologies have the ability to transfer nutrients into a more useful waste stream. The greatest effect of treatment technologies is the transformation of nutrients to more stable forms – such as precipitation of insoluble phosphorus from dissolved phosphorus.

Future Plans

The panel’s report is undergoing final authorization from the Chesapeake Bay Program for release to the public. Future panels may choose to revisit the issue of nutrient reduction from manure treatment technologies. The current panel recommends future panels expand the categories of technologies to include liquid aerobic treatment, and examine more named technologies as they become available within the Chesapeake Bay Watershed.

Corresponding author, title, and affiliation

Douglas W. Hamilton, Associate Professor Oklahoma State University

Corresponding author email

Other authors

Keri Cantrell, KBC Consulting;John Chastain, Clemson University; Andrea Ludwig, University of Tennessee; Robert Meinen, Penn State University; Jactone Ogejo, Virginia Tech; Jeff Porter, USDA Natural Resource Conservation Service, Eastern Technology Suppor

Additional information

https://www.chesapeakebay.net/

http://osuwastemanage.bae.okstate.edu/

Two related presentations given at the same session at Waste to Worth 2017

- Developing science-based estimates of BMP effectiveness

- Recommendations for manure injection and incorporation technologies

Acknowledgements

Funding for this panel was provided by the US EPA Chesapeake Bay Program and Virginia Tech University through EPA Grant No. CB96326201

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2017. Title of presentation. Waste to Worth: Spreading Science and Solutions. Cary, NC. April 18-21, 2017. URL of this page. Accessed on: today’s date.

Poultry Mortality Freezer Units: Better BMP, Better Biosecurity, Better Bottom Line.

Proceedings Home | W2W Home

Purpose

Why Tackle Mortality Management? It’s Ripe for Revolution.

The poultry industry has enjoyed a long run of technological and scientific advancements that have led to improvements in quality and efficiency. To ensure its hard-won prosperity continues into the future, the industry has rightly shifted its focus to sustainability. For example, much money and effort has been expended on developing better management methods and alternative uses/destinations for poultry litter.

In contrast, little effort or money has been expended to improve routine mortality management – arguably one of the most critical aspects of every poultry operation. In many poultry producing areas of the country, mortality management methods have not changed in decades – not since the industry was forced to shift from the longstanding practice of pit burial. Often that shift was to composting (with mixed results at best). For several reasons – improved biosecurity being the most important/immediate – it’s time that the industry shift again.

The shift, however, doesn’t require reinventing the wheel, i.e., mortality management can be revolutionized without developing anything revolutionary. In fact, the mortality management practice of the future owes its existence in part to a technology that was patented exactly 20 years ago by Tyson Foods – large freezer containers designed for storing routine/daily mortality on each individual farm until the containers are later emptied and the material is hauled off the farm for disposal.

Despite having been around for two decades, the practice of using on-farm freezer units has received almost no attention. Little has been done to promote the practice or to study or improve on the original concept, which is a shame given the increasing focus on two of its biggest advantages – biosecurity and nutrient management.

Dusting off this old BMP for a closer look has been the focus of our work – and with promising results. The benefits of hitting the reset button on this practice couldn’t be more clear:

- Greatly improved biosecurity for the individual grower when compared to traditional composting;

- Improved biosecurity for the entire industry as more individual farms switch from composting to freezing, reducing the likelihood of wider outbreaks;

- Reduced operational costs for the individual poultry farm as compared to more labor-intensive practices, such as composting;

- Greatly reduced environmental impact as compared to other BMPs that require land application as a second step, including composting, bio-digestion and incineration; and

- Improved quality of life for the grower, the grower’s family and the grower’s neighbors when compared to other BMPs, such as composting and incineration.

What Did We Do?

We basically took a fresh look at all aspects of this “old” BMP, and shared our findings with various audiences.

That work included:

- Direct testing with our own equipment on our own poultry farm regarding

- Farm visitation by animals and other disease vectors,

- Freezer unit capacity,

- Power consumption, and

- Operational/maintenance aspects;

- Field trials on two pilot project farms over two years regarding

- Freezer unit capacity

- Quality of life issues for growers and neighbors,

- Farm visitation by animals and other disease vectors,

- Operational and collection/hauling aspects;

- Performing literature reviews and interviews regarding

- Farm visitation by animals and other disease vectors

- Pathogen/disease transmission,

- Biosecurity measures

- Nutrient management comparisons

- Quality of life issues for growers and neighbors

- Ensuring the results of the above topics/tests were communicated to

- Growers

- Integrators

- Legislators

- Environmental groups

- Funding agencies (state and federal)

- Veterinary agencies (state and federal)

What Have We Learned?

The breadth of the work at times limited the depth of any one topic’s exploration, but here is an overview of our findings:

- Direct testing with our own equipment on our own poultry farm regarding

- Farm visitation by animals and other disease vectors

- Farm visitation by scavenger animals, including buzzards/vultures, raccoons, foxes and feral cats, that previously dined in the composting shed daily slowly decreased and then stopped entirely about three weeks after the farm converted to freezer units.

- The fly population was dramatically reduced after the farm converted from composting to freezer units. [Reduction was estimated at 80%-90%.]

- Freezer unit capacity

- The test units were carefully filled on a daily basis to replicate the size and amount of deadstock generated over the course of a full farm’s grow-out cycle.

- The capacity tests were repeated over several flocks to ensure we had accurate numbers for creating a capacity calculator/matrix, which has since been adopted by the USDA’s Natural Resources Conservation Service to determine the correct number of units per farm based on flock size and finish bird weight (or number of grow-out days) in connection with the agency’s cost-share program.

- Power consumption

- Power consumption was recorded daily over several flocks and under several conditions, e.g., during all four seasons and under cover versus outside and unprotected from the elements.

- Energy costs were higher for uncovered units and obviously varied depending on the season, but the average cost to power one unit is only 90 cents a day. The total cost of power for the average farm (all four units) is only $92 per flock. (See additional information for supporting documentation and charts.)

- Operational/maintenance aspects;

- It was determined that the benefits of installing the units under cover (e.g., inside a small shed or retrofitted bin composter) with a winch system to assist with emptying the units greatly outweighed the additional infrastructure costs.

- This greatly reduced wear and tear on the freezer component of the system during emptying, eliminated clogging of the removable filter component, as well as provided enhanced access to the unit for periodic cleaning/maintenance by a refrigeration professional.

- Farm visitation by animals and other disease vectors

- Field trials on two pilot project farms over two years regarding

- Freezer unit capacity

- After tracking two years of full farm collection/hauling data, we were able to increase the per unit capacity number in the calculator/matrix from 1,500 lbs. to 1,800 lbs., thereby reducing the number of units required per farm to satisfy that farm’s capacity needs.

- Quality of life issues for growers and neighbors

- Both farms reported improved quality of life, largely thanks to the elimination or reduction of animals, insects and smells associated with composting.

- Farm visitation by animals and other disease vectors

- Both farms reported elimination or reduction of the scavenging animals and disease-carrying insects commonly associated with composting.

- Operational and collection/hauling aspects

- With the benefit of two years of actual use in the field, we entirely re-designed the sheds used for housing the freezer units.

- The biggest improvements were created by turning the units so they faced each other rather than all lined up side-by-side facing outward. (See additional information for supporting documentation and diagrams.) This change then meant that the grower went inside the shed (and out of the elements) to load the units. This change also provided direct access to the fork pockets, allowing for quicker emptying and replacement with a forklift.

- Freezer unit capacity

- Performing literature reviews and interviews regarding

- Farm visitation by animals and other disease vectors

- More research confirming the connection between farm visitation by scavenger animals and the use of composting was recently published by the USDA National Wildlife Research Center:

- “Certain wildlife species may become habituated to anthropogenically modified habitats, especially those associated with abundant food resources. Such behavior, at least in the context of multiple farms, could facilitate the movement of IAV from farm to farm if a mammal were to become infected at one farm and then travel to a second location. … As such, the potential intrusion of select peridomestic mammals into poultry facilities should be accounted for in biosecurity plans.”

- Root, J. J. et al. When fur and feather occur together: interclass transmission of avian influenza A virus from mammals to birds through common resources. Sci. Rep. 5, 14354; doi:10.1038/ srep14354 (2015) at page 6 (internal citations omitted; emphasis added).

- More research confirming the connection between farm visitation by scavenger animals and the use of composting was recently published by the USDA National Wildlife Research Center:

- Pathogen/disease transmission,

- Animals and insects have long been known to be carriers of dozens of pathogens harmful to poultry – and to people. Recently, however, the USDA National Wildlife Research Center demonstrated conclusively that mammals are not only carriers – they also can transmit avian influenza virus to birds.

- The study’s conclusion is particularly troubling given the number and variety of mammals and other animals that routinely visit composting sheds as demonstrated by our research using a game camera. These same animals also routinely visit nearby waterways and other poultry farms increasing the likelihood of cross-contamination, as explained in this the video titled Farm Freezer Biosecurity Benefits.

- “When wildlife and poultry interact and both can carry and spread a potentially damaging agricultural pathogen, it’s cause for concern,” said research wildlife biologist Dr. Jeff Root, one of several researchers from the National Wildlife Research Center, part of the USDA-APHIS Wildlife Services program, studying the role wild mammals may play in the spread of avian influenza viruses.

- Animals and insects have long been known to be carriers of dozens of pathogens harmful to poultry – and to people. Recently, however, the USDA National Wildlife Research Center demonstrated conclusively that mammals are not only carriers – they also can transmit avian influenza virus to birds.

- Biosecurity measures

- Every day the grower collects routine mortality and stores it inside large freezer units. After the broiler flock is caught and processed, but before the next flock is started – i.e. when no live birds are present, a customized truck and forklift empty the freezer units and hauls away the deadstock. During this 10- to 20- day window between flocks biosecurity is relaxed and dozens of visitors (feed trucks, litter brokers, mortality collection) are on site in preparation for the next flock.

- “Access will change after a production cycle,” according to a biosecurity best practices document (enclosed) from Iowa State University. “Empty buildings are temporarily considered outside of the [protected area and even] the Line of Separation is temporarily removed because there are no birds in the barn.”

- Every day the grower collects routine mortality and stores it inside large freezer units. After the broiler flock is caught and processed, but before the next flock is started – i.e. when no live birds are present, a customized truck and forklift empty the freezer units and hauls away the deadstock. During this 10- to 20- day window between flocks biosecurity is relaxed and dozens of visitors (feed trucks, litter brokers, mortality collection) are on site in preparation for the next flock.

- Nutrient management comparisons

- Research provided by retired extension agent Bud Malone (enclosed) provided us with the opportunity to calculate nitrogen and phosphorous numbers for on-farm mortality, and therefore, the amount of those nutrients that can be diverted from land application through the use of freezer units instead of composting.

- The research (contained in an enclosed presentation) also provided a comparison of the cost-effectiveness of various nutrient management BMPs – and a finding that freezing and recycling is about 90% more efficient than the average of all other ag BMPs in reducing phosphorous.

- Quality of life issues for growers and neighbors

- Local and county governments in several states have been compiling a lot of research on the various approaches for ensuring farmers and their residential neighbors can coexist peacefully.

- Many of the complaints have focused on the unwanted scavenger animals, including buzzards/vultures, raccoons, foxes and feral cats, as well as the smells associated with composting.

- The concept of utilizing sealed freezer collection units to eliminate the smells and animals associated with composting is being considered by some government agencies as an alternative to instituting deeper and deeper setbacks from property lines, which make farming operations more difficult and costly.

- Farm visitation by animals and other disease vectors

Future Plans

We see more work on three fronts:

- First, we’ll continue to do monitoring and testing locally so that we may add another year or two of data to the time frames utilized initially.

- Second, we are actively working to develop new more profitable uses for the deadstock (alternatives to rendering) that could one day further reduce the cost of mortality management for the grower.

- Lastly, as two of the biggest advantages of this practice – biosecurity and nutrient management – garner more attention nationwide, our hope would be to see more thorough university-level research into each of the otherwise disparate topics that we were forced to cobble together to develop a broad, initial understanding of this BMP.

Corresponding author (name, title, affiliation)

Victor Clark, Co-Founder & Vice President, Legal and Government Affairs, Farm Freezers LLC and Greener Solutions LLC

Corresponding author email address

Other Authors

Terry Baker, Co-Founder & President, Farm Freezers LLC and Greener Solutions LLC

Additional Information

https://rendermagazine.com/wp-content/uploads/2019/07/Render_Oct16.pdf

Farm Freezer Biosecurity Benefits

One Night in a Composting Shed

—

Avian flu conditions still evolving (editorial)

USDA NRCS Conservation fact sheet Poultry Freezers

How Does It Work? (on-farm freezing)

Influenza infections in wild raccoons (CDC)

Collection Shed Unit specifications

Collection Unit specifications

Freezing vs Composting for Biosecurity (Render magazine)

Manure and spent litter management: HPAI biosecurity (Iowa State University)

Acknowledgements

Bud Malone, retired University of Delaware Extension poultry specialist and owner of Malone Poultry Consulting

Bill Brown, University of Delaware Extension poultry specialist, poultry grower and Delmarva Poultry Industry board member

Delaware Department of Agriculture

Delaware Nutrient Management Commission

Delaware Office of the Natural Resources Conservation Service

Maryland Office of the Natural Resources Conservation Service

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2017. Title of presentation. Waste to Worth: Spreading Science and Solutions. Cary, NC. April 18-21, 2017. URL of this page. Accessed on: today’s date.

Organizing demonstrations and tours for Government officials and Extension on Animal Mortality Management

Proceedings Home | W2W Home

Purpose

Provide some discussion on putting together Tour and Demonstration educational events. To Provide real life demonstrations and educational opportunities dealing with Mortality management.

What did we do?

The agent participated on a multi-state and multi country steering committee to organize and host an international symposium on Animal Mortality and Disposal Management. This was the 5th symposium and had 179 registered attendees from 11 different countries: Australia, Canada, China, Georgia, Korea, New Zealand, Nigeria, the UK, the US, Tunisia, and Vietnam.

The agent served as the host state coordinator (Penn), the 3 bus tour coordinator and the demonstration’s chairperson. Demonstrations included high density foaming, compost pile building and turning, environmental grinder processors, Clean Harbor Industries, truck wash stations, and proper euthanasia with cap and bolt guns. The agent will list the success and challenges of these types of demonstrations and educational events. Results are from the 5th International Symposium on Managing Animal Mortality, Products, and By-products, and Associated Health Risk: Connecting Research, Regulations and Response at the Southeast Agricultural Research and Extension Center on Wednesday, September 30, 2015.

Examples of demonstrations during the field day

What have we learned?

Excellent industry tours and Farm tours and Demonstrations are an excellent learning opportunity. All Parties including Extension, Farmers, Industry and government personnel can benefit from hands on education. Those in attendance gained skills and knowledge to be able to host their own training sessions and to be better prepared to handle animal mortality outbreaks and events in their own state. They gained a first hand experience on pile building and related technologies for this type of event.

Turning of a 60 day compost pile

Future Plans

The International Committee on Animal Mortality and Waste Products is a collection of University researchers and educators, State Department of Agriculture, Federal Homeland Security and Environmental Protection Agency personnel. The committee plans to meet for future International Symposiums as needed.

http://animalmortmgmt.org/symposium/contributors/

Corresponding author, title, and affiliation

J Craig Williams, County Agent, Penn State Extension

Corresponding author email

Additional information

Conference website

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2017. Title of presentation. Waste to Worth: Spreading Science and Solutions. Cary, NC. April 18-21, 2017. URL of this page. Accessed on: today’s date.

Effectiveness of Different Dairy Manure Management Practices in Controlling the Spread of Antibiotics and Antibiotic Resistance

Proceedings Home | W2W Home

Purpose

Even when antibiotics are used judiciously, antibiotic residues, antibiotic resistant bacteria (ARB) and antibiotic resistance genes (ARG) can accumulate in human waste and manure and contribute to the spread of antibiotic resistance. Modern U.S. dairy farms use antibiotics for disease treatment and prevention according to the guidance of veterinary physicians. While dairy manure handling and treatment systems may effectively mitigate antibiotic resistance, the fate of antibiotic residues, ARB and ARG through these systems has not been adequately investigated.

What did we do?

Working cooperatively with 11 dairies in 3 states (NY, PA, MD) our multi-institutional (U. Buffalo, Cornell, U. Maryland, U. Michigan), interdisciplinary team is investigating the effect different manure management practices (e.g. long-term storage, composting, anaerobic digestion, etc.) have on antibiotic residue levels, ARB and ARG. Every 6 weeks for 2 years manure is being collected pre- and post- each treatment step of the various manure handling systems used by each farm. All samples are being characterized and tested for select antibiotic residues (tetracyclines, macrolides, sulfonamides, penicillins and ceftiofurs), with select samples also analyzed for ARB and ARG. To guide these efforts, antibiotic usage and manure treatment system operational data are also being collected for each farm.

What have we learned?

A year of samples has been collected with analysis of antibiotic residues, ARB and ARG on-going. Based on the preliminary data, antibiotic residues are detectable at low-concentrations (< 200 mg/L) in each farm’s manure. Antibiotic residue levels are generally lower in treated manure compared to levels in raw manure, though mitigation efficacy is variable. Early findings show some composting systems have the capacity to lower antibiotic residue levels. Antibiotic residue levels are also lower in separated manure solids, with evidence for partitioning of soluble antibiotic residues into separated manure liquids. At this time, the effects of anaerobic digestion and long-term anaerobic manure storage on antibiotic residue levels remain unclear. Select samples are currently being analyzed for ARB and ARG.

Future Plans

We are entering our second year of field monitoring and ARB and ARG analysis is on-going. Laboratory efforts are also beginning to test the effectiveness of specific anaerobic digester operational parameters at mitigating antimicrobial resistance. Extension/outreach meetings with stakeholder groups are also being planned. The ultimately project goals are to discern the fate of antibiotic residues, ARB and ARG as they move through dairy manure handling systems, identify the efficacy of different manure treatment systems at mitigating antibiotic resistance and extending this knowledge to dairy operators.

Corresponding author, title, and affiliation

Jason Oliver, Postdoctoral Associate at Dept. of Animal Science, Cornell University

Corresponding author email

Other authors

Curt Gooch, Senior Extension Associate at Cornell University, Dept. of Animal Science, PRO-DAIRY

Additional information

Additional project information can be found on the dairy environmental system webpage: www.manuremanagement.cornell.edu

Acknowledgements

This material is based upon work that is supported by the National Institute of Food and Agriculture, U.S. Department of Agriculture, under award number 2016-68003-24601. Any opinions, findings, conclusions, or recommendations expressed in this publication are those of the author(s) and do not necessarily reflect the view of the U.S. Department of Agriculture.

Project collaborators include: (PD) Diana Aga, University of Buffalo, Dept. of Chemistry (Co-PI); her students Mitch Mayville and Jarod Hurst; (Co-PD) Lauren Sassoubre , University of Buffalo, Dept. of Civil, Structural & Environmental Engineering; (Co-PDs) Stephanie Lansing and Gary Felton, Associate Professors at University of Maryland, Dept. of Environmental Science & Technology; their student Jenna Schueler; (Co-PD) Krista Wigginton, Assistant Professor at University of Michigan, Dept. of Civil & Environmental Engineering; Lutgarde Raskin, Professor at University of Michigan, Dept. of Civil & Environmental Engineering; and their student Emily Crossette.

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2017. Title of presentation. Waste to Worth: Spreading Science and Solutions. Cary, NC. April 18-21, 2017. URL of this page. Accessed on: today’s date.

Composting and the Benefits: Achieving Practice Change through Education to Reduce Nutrient Loads and Increase Adoption of Best Management Practices

Purpose

Florida houses roughly 500,000 horses and is also home to 700 freshwater springs; Marion County is, “Horse Capital of the World” and houses two first magnitude springs and each is currently in a restoration plan with the Florida Department Environmental Protection Agency (FDEP). The Florida Department of Agriculture and Consumer Services (FDACS) equine Best Management Practices (BMP) Manual recommends composting as an excellent manure management option.

Composting is a controlled biological process that decomposes and heats up organic material to produce a biologically stable humus, which can then be used as a rich soil amendment. Composting provides protection to the ground and surface waters by preventing excess nutrients from being leached out and running-off into the waters. It destroys up to 90% of weed seeds contained in manure and kills parasite eggs and pathogens. Additionally, the organic matter/compost helps prevent and control soil erosion and can improve both soil quality and productivity.

What did we do?

What did we do?

Individual and group programming has been developed to educate farm owners and managers about the benefits derived from composting horse manure/spent bedding. Since 2007, Over 800 farms have been seen in the county. In 2013 alone, 132 participants were involved in individual farm consultations or farm revisits, group presentations and composting workshops. Education was provided and supplemental materials were developed for clientele about composting manure, compost bin construction and composting’s soil-improvement capabilities.

What have we learned?

Pre and post-test results showed a 62% (82 of 132 total participants) knowledge gain from information taught. A total of 71% (n=12 of 17 farm revisit consultations) of farms revisited improved and adopted recommended manure handling practices after receiving education. Additionally, seven farms and facilities have begun cost-share planning with Southwest Florida Water Management District (SWFWMD) for compost bin construction. Results/impacts show improved management practices and a greater understanding of BMPs, allowing for a decrease in nutrient levels to the ground and surface waters. Pictures show sample bins which were constructed as a result of individual and group programming.

Future Plans

Future Plans

Continued group and individual programming needs to be continued, in partnership with trade journal articles being written about manure management, protection of the ground and surface waters and the benefits derived from composting manure/bedding. Cost-share dollars, coming from state organizations, will further incentivize farms to construct and use compost facilities as part of a regular manure management plan.

Author

Author

Jamie Cohen, Farm Outreach Coordinator, UF/IFAS Extension Marion County jamiecohen@ufl.edu

Additional information

My eXtension.org Manure Management Strategies Webcast: https://connect.msu.edu/p8yko9zhhoq/?launcher=false&fcsContent=true&pbMode=normal

eXtension.org –Manure Management page: https://lpelc.org/horse-manure-management/

A Guide to Composting Horse Manure: www.whatcom.wsu.edu/ag/compost/horsecompost.htm

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2015. Title of presentation. Waste to Worth: Spreading Science and Solutions. Seattle, WA. March 31-April 3, 2015. URL of this page. Accessed on: today’s date.