![]() Waste to Worth home | More proceedings….

Waste to Worth home | More proceedings….

Abstract

In recent years, sharply rising costs of inorganic fertilizers have contributed to an increased demand for manure and compost in crop production acreage, transforming cattle manure from a valueless waste to a viable alternative to commercial fertilizer. If additional demand for manure as a bio-fuel were to arise manure could take on two distinct values, a fertilizer value and a fuel value. This potential “dual” value of manure begs several questions. What would the fertilizer and fuel markets of manure look like? Is there enough manure supply for the markets to operate independently? If not, which market would prevail? In essence, how, if at all, would manure’s potential value as a bio-fuel distort the traditional Panhandle manure market? A modeling framework was developed to assess the potential impacts of a manure-fired ethanol plant on the existing Texas Panhandle manure fertilizer market. Two manure-allocation runs were performed using a spreadsheet model. Run #1 allocated all available manure from dairies and feedlots to cropland as manure fertilizer; run #2 first allocated fuel manure to the ethanol plant and then allocated the remaining manure to cropland. Both model runs assumed a time horizon of one year and no antecedent nutrients in cropland soils. Other constraints included only irrigated acreages received manure and no supplemental fertilizer was used. The model revealed a 6.4% increase in cost per acre of fertilizing with manure for fields whose nutrient requirements were fully satisfied in both runs. The increase in cost per acre was likely due to an increase in hauling distances attributed to fewer CAFOs available for fertilizer manure. The model is not presented as a dynamic, systems model, but rather a static model with the potential to be incorporated into a more dynamic systems-based modeling environment. Suggestions for further model development and expansion including GAMS integration are presented.

Why Model Manure Transport and Use?

To demonstrate the potential for systems modeling to characterize manure flows in response to fertilizer prices, biofuel demand, and other externalities in the Texas Panhandle

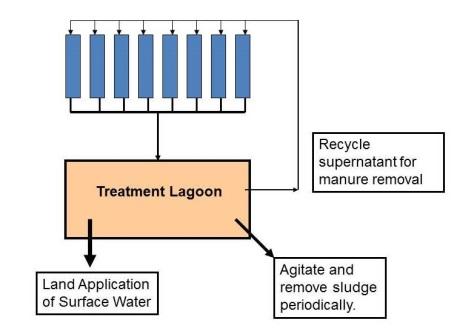

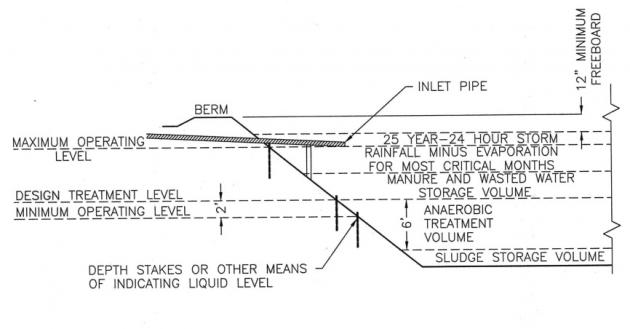

Conceptual model diagram. |

What Did We Do?

We develeloped a spreadsheet based modeling framework to evaluate how both manure use and transport might be affected by regional changes in fertilizer prices, crop composition, and biofuel demand. Specifically, we evaluated how traditional fertilizer valued manure flows might be affected by potential biofuel based flows stemming from a proposed manure-fired ethanol plant. Two model simulations representing manure flows with and without biofuel manure demand from the proposed plant were performed.

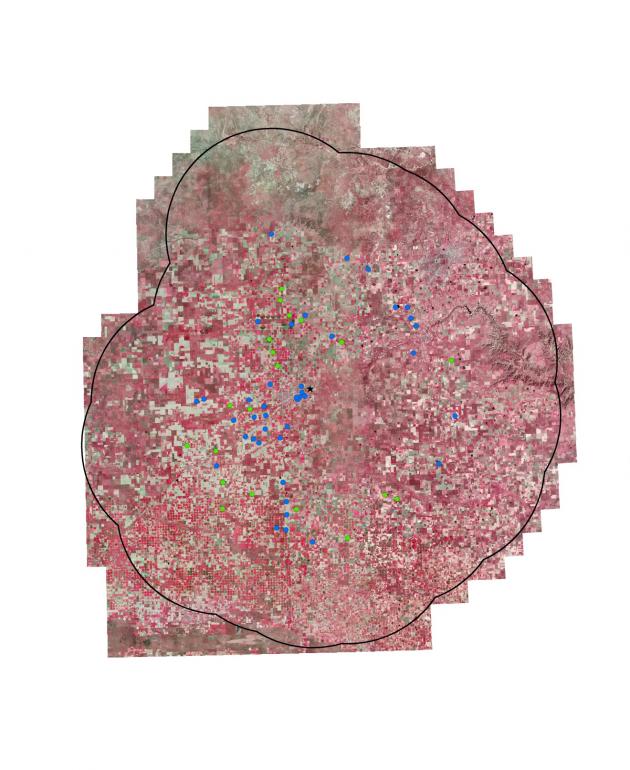

Explicit model boundary shown with TNRIS satellite imagery used to locate and identify center pivot irrigated fields. |

What Have We Learned?

Although the cattle industry in Texas Panhandle generates a substantial volume of manure, almost all of it is land applied as fertilizer. However, the introduction of manure-fired facilities such as the proposed ethanol plant would undoubtedly change the dynamics of the existing manure market by introducing at least additional demand, if not a second value-based market. Assuming only transportation costs of acquiring manure for biofuel, our model simulations suggested a 6.4% increase in cost per acre for lands whose manure requirements were fully satisfied in both simulations. Assuming that manure for biofuel received an allocation preference for proximity to the plant, we propose that costs associated with having to transport manure over longer distances significantly contributes the the increased cost per acre for fertilized lands.

In terms of what we learned about systems modeling, we have experienced (although anticipated) that translating broad, systems based conceptual modeling ideas into an explicit, user friendly, and robust modeling interface can be extremely challenging. Although systems-based modeling efforts occur largely at a macro level, they often require extensive supplemental datasets. We have experienced difficulty in identifying software packages that are equipped to adequately handle both aspects of systems modeling.

Future Plans

We plan to continue to develop and expand the current modeling framework by incorporating a GIS-based water availability aquifer component, expanding the current crop-composition database, and providing logic algorithms for producer-based management decisions using GAMS (General Algebraic Modeling System) optimization modeling.

Manure allocation map for model run #1 (232 LMU cells allocated). |

Authors

Brent Auvermann, Professor of Biological and Agricultural Engineering, Texas A&M AgriLife Research, b-auvermann@tamu.edu

Gary Marek, Postdoctoral Research Associate, Texas A&M AgriLife Research; Brent W. Auvermann, Professor of Biological and Agricultural Engineering, Texas A&M AgriLife Research; Kevin Heflin, Extension Associate, Texas A&M AgriLife Extension

Additional Information

Please contact Gary Marek, Postdoctoral Research Associate, Texas A&M AgriLife Research, 6500 Amarillo Boulevard West, Amarillo TX, 79106, Phone: 806-677-5600, Email: gwmarek@ag.tamu.edu or Brent W. Auvermann, Professor of Biological and Agricultural Engineering, Texas A&M AgriLife Research, 6500 Amarillo Boulevard West, Amarillo TX, 79106, Phone: 806-677-5600, Email: b-auvermann@tamu.edu.

Acknowledgements

Special thanks to Dr. Raghavan Srinivasan and David Shoemate of the Texas A&M University Department of Ecosystem Science and Management Spacial Sciences Laboratory for their help in GIS processing scripts.

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2013. Title of presentation. Waste to Worth: Spreading Science and Solutions. Denver, CO. April 1-5, 2013. URL of this page. Accessed on: today’s date.