To be sustainable, producers need to conserve energy while still maintaining or improving their facilities and the lives of the animals they house. This presentation was originally broadcast on December 15, 2023. Continue reading “Energy Conservation in Livestock and Poultry Operations”

Improving disease identification, treatment, & antibiotic stewardship in livestock production

This webinar will focus on assisting livestock farmers and veterinarians to better identify, diagnose, and treat sick animals with the goal of improving farm efficiency and antibiotic stewardship. This webinar is brought to you by the iAMResponsibleTM Project, a nationwide team of researchers and extension experts working to develop and deliver effective outreach on antimicrobial resistance for diverse audiences. This presentation was originally broadcast on August 18, 2023. Continue reading “Improving disease identification, treatment, & antibiotic stewardship in livestock production”

Responsible Antibiotic Use on Dairy Farms

Are you ready for a pop quiz?

Off the top of your head, how would you answer the following questions:

-

- How often do dairy cattle receive antibiotics in dairy farms in the US?

- a) Daily

- b) As needed and advised by a veterinarian

- Are there more antibiotics in milk from cows raised without antibiotics or cows raised on conventional farms?

- a) Conventional farms

- b) Neither, all milk is tested and removed from the food supply if it contains antibiotics, no matter the source.

- How often do dairy cattle receive antibiotics in dairy farms in the US?

Continue reading “Responsible Antibiotic Use on Dairy Farms”

Trends in Manure Sample Data

Purpose

Most manure book values used today from the MidWest Plan Service (MWPS) and American Society of Agricultural and Biological Engineers (ASABE) were derived from manure samples prior to 2003. To update these manure test values, the University of Minnesota in partnership with the Minnesota Supercomputing Institute, is working to build a dynamic manure test database called ManureDB. During this database construction, the University of Minnesota collected manure data spanning the last decade from five labs across the country. Trends, similarities, and challenges arose when comparing these samples. Having current manure test numbers will assist in more accurate nutrient management planning, manure storage design, manure land application, and serve agricultural modeling purposes.

What Did We Do?

We recruited five laboratories for this preliminary study who shared some of their manure sample data between 2012-2021, which represented over 100,000 manure samples. We looked at what species, manure types (liquid/solid), labels, and units we had to work with between the datasets to make them comparable. Once all the samples were converted into either pounds of nutrient/ton for solid manure or pounds of nutrient/1000 gallons for liquid manure, we took the medians of total nitrogen, ammonium-nitrogen (NH4-N), phosphate (P2O5), and potassium oxide (K2O) analyses from those samples and compared them to the MWPS and ASABE manure nutrient values.

What Have We Learned?

There is no standardization of laboratory submission forms for manure samples. The majority of samples have minimal descriptions beyond species of animal and little is known about storage types. With that said, we can still detect some general NPK trends for the beef, dairy, swine, poultry manure collected from the five laboratories in the last decade, compared to the published book values. For liquid manure, the K2O levels generally increased in both the swine and poultry liquid manure samples. For the solid swine manure and solid beef manure, total N, P2O5, and K2O levels all increased compared to the published book values. The solid dairy manure increased in P2O5 and K2O levels, and the solid poultry manure increased in total N and K2O. See Figure 1 for the general trends in liquid and solid manure for swine, dairy, beef, and poultry.

Table 1. Manure sample trends 2012-2021 compared to MWPS/ASABE manure book values. (+) = trending higher, (o) = no change/conflicting samples, (-) = trending lower

| Liquid | Total N | NH4–N | P2O5 | K2O |

| Swine | o | o | – | + |

| Dairy | – | o | – | o |

| Beef | o | o | o | o |

| Poultry | o | + | – | + |

| Solid | Total N | NH4–N | P2O5 | K2O |

| Swine | + | o | + | + |

| Dairy | o | o | + | + |

| Beef | + | – | + | + |

| Poultry | + | o | o | + |

Future Plans

The initial data gives us a framework to standardize fields for the future incoming samples (location, manure type, agitation, species, bedding, storage type, and analytical method) along with creating a unit conversion mechanism for data uploads. We plan to recruit more laboratories to participate in the ManureDB project and acquire more sample datasets. We will compare and analyze this data as it becomes available, especially more detailed data for each species. We will be designing ManureDB with statistical and data visualization features for future public use.

Authors

Nancy L. Bohl Bormann, Graduate Research Assistant, University of Minnesota

Corresponding author email address

Additional authors

Melissa L. Wilson, Assistant Professor, University of Minnesota

Erin L. Cortus, Associate Professor and Extension Engineer, University of Minnesota

Kevin Janni, Extension Engineer, University of Minnesota

Larry Gunderson, Pesticide & Fertilizer Management, Minnesota Department of Agriculture

Tom Prather, Senior Software Developer, University of Minnesota

Kevin Silverstein, Scientific Lead RIS Informatics Analyst, University of Minnesota

Additional Information

ManureDB website: http://manuredb.umn.edu/ (coming soon!)

Twitter: @ManureProf, @nlbb

Lab websites:

https://wilsonlab.cfans.umn.edu/

https://bbe.umn.edu/people/erin-cortus

Acknowledgements

This work is supported by the AFRI Foundational and Applied Science Program [grant no. 2020-67021-32465] from the USDA National Institute of Food and Agriculture, the University of Minnesota College of Food, Agricultural and Natural Resource Sciences, and the Minnesota Supercomputing Institute.

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2022. Title of presentation. Waste to Worth. Oregon, OH. April 18-22, 2022. URL of this page. Accessed on: today’s date.

NAEMS: How It Was Done and Lessons Learned

Building Environment and Air Quality – Presented by Al Heber

Development of Draft Emission Estimating Methodologies for AFOs: Process Overview – Presented by Ian Rumsy

National Air Emissions Monitoring Study Status Update – Presented by Bebhinn Do

Purpose

The National Air Emissions Monitoring Study, or NAEMS, was conducted from 2007 – 2010 to gather data to develop scientifically credible methodologies for estimating emissions from animal feeding operations (AFOs). It followed from a 2002 report by the National Academy of Sciences that recommended the development of the emission models. NAEMS was funded by the AFO industry as part of a 2005 voluntary air compliance agreement with the U.S. Environmental Protection Agency (EPA). The goals of the air compliance agreement were to reduce air pollution, monitor AFO emissions, promote a national consensus on emissions estimating methodologies, and ensure compliance with requirements of the Clean Air Act and notification provisions of the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA), and the Emergency Planning and Community Right-to-Know Act (EPCRA). Thus, the design of the study was based both on principles set forth by the National Academy of Sciences and on the needs of EPA and the AFO industry to satisfy the compliance agreement.

What Did We Do

NAEMS monitored barns and lagoons at 25 AFOs in 10 states for approximately 2 years each to measure emissions of ammonia, hydrogen sulfide, particulate matter, and volatile organic compounds. University researchers conducted this monitoring with EPA oversight. The types of AFOs monitored included swine, broiler chickens, egg-laying operations, and dairies. Participating AFOs made their operations available for monitoring for two years and cooperated with the researchers, industry experts, and EPA during the study.

In 2012, EPA used information gathered in NAEMS, along with information provided as part of a 2011 Call for Information, to develop draft emission models for some of the AFO sectors that were monitored. The EPA Science Advisory Board (SAB) conducted a peer review of these original draft emission models and made suggestions for improving the models. Since 2017, EPA began applying the SAB suggestions and developing new draft emission models for each AFO sector. The models estimate farm-scale emissions using information that producers already record or is easy to get (like weather data). The models are not “process-based.” However, the approach aims to estimate emissions from sources based on statistical relationships between air emissions and the meteorological and housing parameters collected that are known to affect processes that generate emissions. The development of process-based models remains a long-term goal of the agency, as we acknowledge process-based models improve the accuracy of emission estimates for the livestock and poultry sectors.

What Have We Learned

During the workshop, panelists will discuss in more detail the lessons learned at various stages of the NAEMS project and how those lessons could inform future work.

Future Plans

The EPA team continues to develop draft emission models using the NAEMS data. It is anticipated that the AFO emission models will be finalized after incorporating input from a stakeholder review period.

Authors

Presenting Authors

-

- Albert J. Heber, Professor Emeritus, Agricultural and Biological Engineering

- Ian C. Rumsey, Physical Scientist, Office of Research & Development, U.S. Environmental Protection Agency

- Bebhinn Do, Physical Scientist, U.S. Environmental Protection Agency

Corresponding Author

Bebhinn Do, Physical Scientist, U.S. Environmental Protection Agency

do.bebhinn@epa.gov

Additional Information

For updates on NAEMS, please see: https://www.epa.gov/afos-air/national-air-emissions-monitoring-study

Acknowledgements

U.S. Environmental Protection Agency – Office of Research & Development Emission Estimating Methodology development team: Maliha Nash, John Walker, Yijia Dietrich, Carry Croghan

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2022. Title of presentation. Waste to Worth. Oregon, OH. April 18-22, 2022. URL of this page. Accessed on: today’s date.

Estimating Routine Beef and Dairy Mortality Masses Based on Systems Operation

Purpose

The day-to-day loss of animals is a fact of life all cattle producers must face and prepare for. Unfortunately, most published data of animal mortalities are for one-time, catastrophic die offs – where all the cattle on a farm must be exterminated because of disease outbreaks or natural disasters. Routine mortalities on cattle farms do not happen all at once, and mortality rates vary greatly between different life stages of animals and types of production systems.

An expert panel was convened by the Agricultural Working Group of the Chesapeake Bay Program to determine annual mortality, nitrogen and phosphorus masses produced by cow-calf, dairy and cattle on feed (feedlot) operations in the watershed. This paper concentrates on the annual mortality masses estimations determined by the panel. Cattle and Dairymen can use these values to plan for disposal of routine losses.

What Did We Do?

The panel looked, at depth, into existing production systems, and combined morality rates at different life stages, the size of animals at time of death, and the carcass composition varying with age to determine mortality and nutrient masses produced by typical cattle farms in the watershed.

The panel chose a 50-cow cow-calf operation as a model system, where cattle are on pasture 95% of the time. Under ideal conditions, each cow will yield one calf per year to be sold by year’s end. Some female calves will be retained to replace culled cows from the herd, maintaining the same general herd size. It was assumed there was no death loss of mother cows in the herd. We used USDA-APHIS (2010) data of average annual death loss of immature cattle combined with the average weight of cattle at different life-stages to determine weight of mortalities produced each year.

A total confinement beef feedlot was used to model mortalities for cattle on feed. Cattle were assumed to grow linearly with cattle placed in the feedlot at 400 to 600 pounds, and leaving at 1,000 to 1,200 pounds with an average time on lot of 120 days. Midwestern data (Vogel et al, 2015) was used to estimate annual deathrates per feedlot space at 30-day increments since placement in the feedlot.

A 100-cow milking herd was used as a reference for dairy systems. The reference farm contained 50 female calves and 50 heifers in development. Heifers are bred at 15 months and give birth around 24 months (2 years) of age. Male calves are exported from the farm as soon as possible for development as lower grade beef cattle. The reference dairy had heifers and dry cows on pasture, with the active milking herd in free-stall barns or alternative confinement for a 300-day lactation. USDA-APHIS (2016) data of average annual death loss of all types of dairy cattle was combined with the average weight of cattle at different life-stages to determine weight of mortalities produced each year.

What Have We Learned?

Figure 1 shows the estimated total weight of mortalities produced by a 50 cow, cow-calf herd each year broken down by age of animal dying. As can be seen in Figure 1, the greatest weight of mortalities occurred before calves were weaned – assuming no death of mother cows. The values in Figure 1 represent 1.52 calves born dead, 1.92 calves dying before weaning, and 0.87 head dying after weaning. This means a farmer should prepare for the loss of 2 newborn calves, 2 un-weaned calves, and one weaned steer/heifer per 50 mother cows each year. Dividing the total weight of mortalities by 50 head gives an average per cow annual mortality of 32 pounds per year.

Figure 2 shows the estimated total weight of mortalities produced by a 100-head-space feedlot. The greatest source of mortalities is steers and heifers weighing close to 700 pounds (31 to 60 days after arrival on the feedlot. Dividing the total weight of mortalities by 100 gives an average annual mortality weight of 18 pounds per head-space per year. The feedlot owner should prepare for approximately 3 animals dying each year per 100 head-space.

Figure 3 shows the estimated total weight of mortalities produced by a 100-cow dairy. Dividing the total weight of mortalities by 100 head gives an average annual mortality weight of 90 pounds per milking cow. The greatest source of mortalities is mature cows. Dairies should prepare for as much as 6 mature cows, 3 pre-weaned calves and heifers, and 1 weaned heifer dying each year per 100 mature cows.

Future Plans

Cattle producers can use the values estimated by this project to determine resources needed to prepare for mortalities. If burial is the preferred option, the space required to bury mortalities for the expected life of the operation; for composting, the area, and weight of carbon source required to compost; and for incineration, an incinerator capable of handling the largest animal housed on the farm.

Authors

Douglas W. Hamilton, Ph.D. P.E., Extension Waste Management Specialist, Oklahoma State University

Corresponding author email address

dhamilt@okstate.edu

Additional authors

Thomas M. Bass, Livestock Environment Associate Specialist, Montana State University; Amanda Gumbert, PhD., Water Quality Extension Specialist, University of Kentucky; Ernest Hovingh, DVM, PhD., Research Professor Extension Veterinarian, Pennsylvania State University; Mark Hutchinson, Extension Educator, University of Maine; Teng Teeh Lim, PhD, P.E., Extension Professor, University of Missouri; Sandra Means, P.E., USDA NRCS, Environmental Engineer, East National Technology Support Center (Retired); George “Bud” Malone, Malone Poultry Consulting; Jeremy Hanson, WQGIT Coordinator – STAC Research Associate, Chesapeake Research Consortium – Chesapeake Bay Program

Additional Information

Hamilton, D., Bass, T.M., Gumbert, A., Hovingh, E., Hutchinson, M., Lim, T.-T., Means, S., and G. Malone. (2021). Estimates of nutrient loads from animal mortalities and reductions associated with mortality disposal methods and Best Management Practices (BMPs) in the Chesapeake Bay Watershed (DRAFT). Edited by J. Hanson, A. Gumbert & D. Hamilton. Annapolis, MD: USEPA Chesapeake Bay Program.

USDA-APHIS (2010). Mortality of Calves and Cattle on U.S. Beef Cow-calf Operations: Info Sheet, 2010. Fort Collins, CO: USDA-APHIS.

USDA-APHIS. (2016). Dairy 2014: Health and Management Practices on US Dairy Operations, 2014. Report, 3, 62-77. Fort Collins, CO: USDA-APHIS,.

Vogel, G. J., Bokenkroger, C. D., Rutten-Ramos, S. C., & Bargen, J. L. (2015). A retrospective evaluation of animal mortality in US feedlots: rate, timing, and cause of death. Bov. Pract, 49(2), 113-123.

Acknowledgements

Funding for this project was provided by the US-EPA Chesapeake Bay Program through Virginia Polytechnic and State University EPA Grant No. CB96326201

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2022. Title of presentation. Waste to Worth. Oregon, OH. April 18-22, 2022. URL of this page. Accessed on: today’s date.

Manure Treatment Technology Adoption by Swine and Dairy Producers: Survey Feedback

Purpose

Sound management of manure is essential to optimize its benefits for soil health and crop production, and to minimize costs and environmental risks. Along with changes in farm scale and practices, modern farms are increasingly looking to process or treat manure to address problem areas and to take advantage of market opportunities on their operations. A variety of manure treatment technologies are available and new technologies continue to be developed for managing nutrients, solids, energy, water, and other components of manure. But, while these new treatment technologies hold potential to improve the environmental, economic, and social sustainability of livestock and poultry production, questions remain regarding producer adoption of treatment systems on their operations. To improve our understanding of decision-making processes employed when producers evaluate and adopt manure treatment technologies, the authors conducted a survey aimed at dairy and swine producers in the Midwest.

What did we do?

Two surveys were developed, one tailored to dairy producers and one for swine producers. All operation sizes and production systems were included. The surveys were administered using Qualtrics, an online survey platform. Questions asked covered manure-related practices in animal facilities, manure handling, and land application. Additional questions asked producers to prioritize their needs for manure treatment, factors influencing technology selection, current technologies being utilized, and principal barriers for adoption. Respondents were asked to select up to three critical outcomes for their farms’ manure treatment technologies, the most influential factors (or technology characteristics) for manure treatment adoption, and the main barriers for technology adoption. The authors collaborated with Nebraska Extension and with state producer associations to reach swine and dairy producers in Nebraska and other Midwest states, with the survey first launched in the fall of 2021. Magazine articles, radio programs, listservs, and social media were used to promote the surveys.

Responses were analyzed using descriptive methods. Eighteen respondents provided information to characterize seven swine farms and ten dairy operations. Swine respondents had farms in Nebraska (7), Iowa (2), and Ohio (1). For dairy, 7 of the farms were in Nebraska and 1 was in Minnesota. Swine farm systems were divided between the ones that had farrowing (farrow-to-finish and farrow-to-wean systems) and the ones without it (grow-to-finish and wean-to-finish systems) (Table 1). Respondents were asked to provide insights for their farms’ primary manure management systems. A dairy operation’s primary manure management system was defined as the one receiving manure from the lactating cows. For swine, the primary manure management system received manure from the gestation sows or the finishing herd. For both swine and dairy, secondary systems were defined as utilizing separate storage and handling facilities.

| Species and herd type | Number of farms | Herd size – average | Herd size – range |

|---|---|---|---|

| Dairy – lactating cow herd | 8 | 933 | 30 to 2,150 |

| Swine (farrowing) – sow herd | 4 | 2,762 | 250 to 7,500 |

| Swine (finishing) – finisher herd | 5* | 23,600 | 1,200 to 70,000 |

| Note: *One finishing farm did not share its herd size information. | |||

What have we learned?

The dairy and swine farms demonstrated differences in manure treatment needs and consequently adopted different treatment technologies (Figures 1 and 2).

FTF = farrow-to-finish

PSOP = partially slotted open pens

PP = pull-plugs

FTW = farrow-to-wean

ISWPSF = individual stalls w/partial slotted floor

DP = deep pits

GF-F = grow-finish or finishing

ASFB = all slotted-floor building

FL = flushing

WTF = wean-to-finish

CH = chemicals

AE = aeration

LA = lagoons

AD = anaerobic digestion

CO = composting

CS = corn stalks

Sd = sedimentation

DD = direct drying

Mch = mechanical

TL = treatment lagoon

Co = composting

Stt = sand settling lane or basin

AE = aeration

NS = no separation

AD = anaerobic digestion

The most-used technologies in the primary manure management system for each industry were: mechanical separation, sand settling lanes, and sedimentation basins for dairy farms; and addition of chemicals, treatment lagoons, and composting for swine operations (Figure 3).

Allowing water to be reused and exporting nutrients were the primary desired outcomes of implementing manure treatment technologies for dairy and swine farms, respectively (Figure 4). Accordingly, 6 of 7 dairy farms were recycling water in their operations, while only 1 out of 10 was doing so on the swine side.

Diverse factors influenced the selection of the implemented technologies in both livestock operations. Low management demand, low maintenance, “performs best functionally” (best performance achieving the desired goals of manure treatment), and low initial cost are among the most-mentioned factors (Figure 5).

Swine and dairy farmers identified initial cost, operational cost, and return on investment as the primary barriers to future technology adoption (Figure 6). Management demand was another important barrier among swine producers.

None of the survey respondents used membranes, electrochemical precipitation, or gasification technologies, demonstrating that cutting-edge manure treatment technologies are being more slowly adopted by regional livestock producers. The high cost and potential high management demand of these technologies could be barriers for their adoption.

Future plans

Our research work has moved into qualitative exploration. Focus groups will be held with swine and dairy producers, where they will discuss and share their manure treatment needs and desired outcomes from new treatment options. These activities will be organized online and will allow producers to share their manure management perspectives for the present and future. The results of our surveys and focus groups are being used to inform a decision-support tool being developed as part of the Management of Nutrients for Reuse (MaNuRe) project. Our findings will also be used to help develop extension programs that meet the needs of producers for manure management in Nebraska and neighboring states.

Authors

Juan Carlos Ramos Tanchez, Graduate Research Assistant, University of Nebraska-Lincoln.

Corresponding author email address

jramostanchez2@huskers.unl.edu

Additional authors

Richard Stowell, Professor of Biological Systems Engineering, University of Nebraska-Lincoln.

Amy Schmidt, Associate Professor of Biological Systems Engineering, University of Nebraska-Lincoln.

Acknowledgements

Funding for this effort came from the USDA NIFA AFRI Water for Food Production Systems program, grant #2018-68011-28691. The authors would like to express gratitude to Dr. Teng Lim and Timothy Canter (University of Missouri), Mara Zelt, and Lindsey Witt-Swanson (University of Nebraska-Lincoln) for their relevant support to this study. We would also like to thank the staff at the Nebraska Pork Producers Association and the Nebraska State Dairy Association for their collaboration on our research.

Opportunities and Challenges for Dairy Manureshed Across the US

Purpose

The “manureshed” refers to the land base needed to assimilate the nutrients produced by a livestock operation without presenting a danger to water, land, and air resources. Trends toward large dairies in many regions of the US, often with high density of livestock relative to the amount of land available for nutrient application, have increased in recent decades. Consequently, import of feed and forage often leads to nutrient surpluses and the need to transport manure off farm for land application. Our purpose was to evaluate the status of dairy manuresheds across the US to highlight challenges and opportunities to improve nutrient balances and facilitate manure nutrient redistribution when needed.

What Did We Do

Our group produced case-studies of manureshed management from four major dairy producing states across the US. We reviewed the predominate structure of dairies in those states and analyzed the primary challenges that must be addressed to safely assimilate nutrients. We focus on reviewing the extent of off-farm redistribution of manure that is needed in each of those states, limitations to redistribution, and approaches that can be built upon to facilitate redistribution. In the Minnesota case-study, where nutrient management data is publicly available for Confined Feeding Operations, GIS software was used to estimate manure transport distances for varying cropping systems and dairy cattle breeds. For Idaho, New Mexico, and Pennsylvania, whole-farm modelling is referenced to understand nitrogen (N) and phosphorous (P) balances on a range of dairies.

What Have We Learned

Soil P assimilation capacity was the predominate factor constraining manureshed land requirements in three of the four states studies. However, nitrate leaching potential was the largest constraint in New Mexico, where dairy forages were largely grown on irrigated lands near rivers. GIS analysis in Minnesota estimated that an average travel distance of 4.1 km for manure transport was required for dairy with 1000 or more cows. The Minnesota case-study also revealed smaller manuresheds were required, per unit of energy-corrected milk, for Jersey cattle compared to the larger Holsteins. Modelled nutrient budgets for Idaho indicated a greater need for off-farm transport, suggesting that expanded application of dairy manures on alternative crops (such as potatoes, sugar beets, and barley) should be considered. In New Mexico, large dairies and limited cropland has caused extensive import of feed from other states and Mexico, with informal nutrient brokering networks developing. In Pennsylvania, dairy producing counties are largely overall sinks for nutrients, but historic heavy manure applications on fields near dairy barns often necessitates greater redistribution of manure nutrients within individual dairies or transfer to local crop farms.

Multiple approaches for improving nutrient balances and distribution of manure were identified in the case studies. Continuing advances in dairy nutrition and cattle genetics are helping to improve nutrient balances and reduce quantities of N and P excreted. When nutrient surpluses necessitate off-farm transport, informal networks for connecting dairies with surplus nutrients with crop farms that have nutrient assimilation capacity, described in New Mexico, provide a basis for development of similar networks elsewhere. Manure processing developments also provide possibilities for more economical transport or reuse of manure nutrients from farms with liquid handling.

Future Plans

The current work provides an overview of the current status of manureshed management in dairy regions. Continuing work is needed to refine nutrient balances for individual farms and to continue to develop tools that assist farmers in understanding nutrient balances and manureshed requirements on their farms. Involvement of social scientists and economists is needed to further develop networks for manure redistribution. Our work also points to the need for greater federal and state cost sharing and more technical support from government, universities, and farm organizations to facilitate more intensive evaluation of manureshed requirements and transport of manure when needed.

Authors

Curtis Dell, Soil Scientist, USDA-ARS, Pasture Systems and Watershed Management Research Unit, University Park, PA

Curtis.Dell@usda.gov

Additional Authors

-

- John Baker, USDA-ARS, St. Paul, MN

- Sheri Spiegal, USDA-ARS, Las Cruces, NM

- Sarah Porter, Environmental Working Group, Minneapolis, MN

- April Leytem, USDA-ARS, Kimberly, ID

- Colton Flynn, USDA-ARS, Temple, TX

- Alan Rotz, USDA-ARS, University Park, PA

- David Bjornberg, USDA-ARS, Kimberly, ID

- Ray Bryant, University Park, PA

- Robert Hagevoort, New Mexico State Univ., Clovis, NM

- Jeb Williamson, New Mexico State Univ., Las Cruces, NM

- Amalia Slaughter, USDA-ARS, Las Cruces, NM

- Peter Kleinman, USDA-ARS, Fort Collins, CO

Additional Information

C.J. Dell et al., 2022. Challenges and opportunities for manure management across US Dairy systems: Case Studies from four regions. Journal of Environmental Quality. (In press in pending special edition on manureshed management).

Acknowledgements

USDA Agricultural Research Service and the Dairy Agroecosystems Workgroup (DAWG, USDA-ARS)

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2022. Title of presentation. Waste to Worth. Oregon, OH. April 18-22, 2022. URL of this page. Accessed on: today’s date.

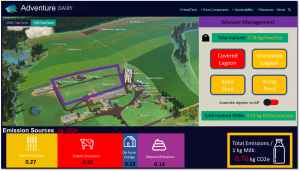

Adventure Dairy: Educational and Technical Tools for Carbon Cycle Modeling on a Virtual Dairy Farm

Conceptualizing, modeling, and controlling carbon flows at the farm scale can improve efficiency in production, reduce costs, and promote beneficial products and byproducts of agricultural processes through best management practices. On dairy farms, opportunities exist for farmers to control factors affecting greenhouse gas (GHG) emissions and diversions from production and operations. Complex programs to model the effects of different carbon management strategies on net emissions are very useful to farmers, but lack visualization of flows through a user interface to show effects of different management choices in real time.

Previously, a collaborative research team at Penn State University and the University of Wisconsin-Madison has developed a Virtual Dairy Farm website to share information about how dairy farms incorporate best management practices and other on-farm production choices to reduce environmental impacts. The website is organized in two model farm configurations, a 150-cow and a 1500-cow modern dairy farm. Website users can find information on different components of the farm by exploring locations on the farm. Links to information about farm operations are structured in multiple levels such that information is understandable to the general public but also supported by technical factsheets for agriculture professionals.

What did we do?

Building on the strengths of the Penn State Virtual Dairy Farm interactive website, the Team has developed a concept for an “Adventure Dairy” package for users to explore how management choices affect total on-farm GHG emissions for a model Pennsylvania dairy farm (Figure 1). Five main categories serve as management portals superimposed on the Virtual Dairy interface, including Cow Life Cycle, Manure Management, Crop Production, Energy Use on Farm, and Feed on Farm.

For each category, users can select from multiple options to see how these decisions increase or decrease emissions. Along the bottom of the webpage, a calculator displays the net carbon balance for the model system and change emissions estimates as users choose feed composition, land use strategies, and other important components (Figure 2). Under each category, users can make choices about different management practices that affect on-farm carbon cycling. For example, different choices for feed additives change total net GHG emissions, and, in turn, can affect total manure production. A change in management and operational choices, such as storage, is visually communicated through interactions and on the interface (Figure 3). These management portals can be seamlessly integrated with the Virtual Dairy Farm as an addition to the right sidebar. The click-through factsheets currently a part of the interface can be preserved through new informational “fast facts” overlays with accompanying infographics and charts. Pathways to optimizing carbon flows to ensure maximum production and minimum environmental impact will be featured as “demo” examples for users.

What have we learned?

This model offers a novel platform for more interactive software programs and websites for on-farm modeling of carbon emissions and will inform future farm management visualizations and data analysis program interfaces. The Team envisions the Adventure Dairy platform as an important tool for Extension specialists to share information with dairy professionals about managing carbon flows on-farm. Simultaneously, consumers increasingly seek information on the environmental impacts of agriculture. This interactive website is a valuable educational and technical tool for a variety of audiences.

Uniquely, a multidisciplinary team of agriculture and engineering graduate students from multiple institutions are leading this project, as facilitated by faculty. This Cohort Challenge model allows for graduate students to engage with complex food-energy-water nexus problems at the level of faculty investigators in a virtual educational resource center. Future INFEWS-ER teams and “wicked problems” challenge projects will continue to develop this model of learning and producing novel research products.

Future plans

The Cohort Challenge Team is entering a peer/faculty review process of the simplified carbon model for the Virtual Dairy Farm website. The user interface for the Adventure Dairy calculator is not currently a part of the Penn State Virtual Dairy Farm. The Team will be working with software developers to integrate our model in the existing interface. Additional components under consideration for inclusion in the Adventure Dairy calculator include cost comparisons for different best management practices, an expanded crop production best management calculator, and incorporation of

Authors

Student Team: Margaret Carolan,1 Joseph Burke,2 Kirby Krogstad,3 Joslyn Mendez,4 Anna Naranjo,4 and Breanna Roque4

Project Leads: Deanne Meyer,4 Richard Koelsch,3 Eileen Fabian,5 and Rebecca Larson6

- Department of Civil and Environmental Engineering, University of Iowa, Iowa City, IA crln@uiowa.edu

- Texas A&M University

- University of Nebraska-Lincoln

- University of California-Davis

- Penn State University

- University of Wisconsin-Madison

Acknowledgements

Funding for the INFEWS-ER was provided by the National Science Foundation #1639340. Additional support was provided by the National Institute for Food and Agriculture’s Sustainable Dairy CAP and the National Center for Supercomputing Applications at the University of Illinois at Urbana-Champaign.

Useful resources

- Penn State Virtual Dairy Farm: http://virtualfarm.psu.edu/

- INFEWS-ER: http://infews-er.net/

- Sustainable Dairy CAP: http://www.sustainabledairy.org/Pages/home.aspx

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2019. Title of presentation. Waste to Worth. Minneapolis, MN. April 22-26, 2019. URL of this page. Accessed on: today’s date.

The Use of USDA-NRCS Conservation Innovation Grants to Advance Air Quality Improvements

USDA-NRCS has nearly fifteen years of Conservation Innovation Grant project experience, and several of these projects have provided a means to learn more about various techniques for addressing air emissions from animal agriculture. The overall goal of the Conservation Innovation Grant program is to provide an avenue for the on-farm demonstration of tools and technologies that have shown promise in a research setting and to further determine the parameters that may enable these promising tools and technologies to be implemented on-farm through USDA-NRCS conservation programs.

What Did We Do?

Several queries for both National Competition and State Competition projects in the USDA-NRCS Conservation Innovation Grant Project Search Tool (https://www.nrcs.usda.gov/wps/portal/nrcs/ciglanding/national/programs/financial/cig/cigsearch/) were conducted using the General Text Search feature for keywords such as “air”, “ammonia”, “animal”, “beef”, “carbon”, “dairy”, “digester”, “digestion”, “livestock”, “manure”, “poultry”, and “swine” in order to try and capture all of the animal air quality-related Conservation Innovation Grant projects. This approach obviously identified many projects that might be related to one or more of the search words, but were not directly related to animal air quality. Further manual review of the identified projects was conducted to identify those that specifically had some association with animal air quality.

What Have We Learned?

Out of nearly 1,300 total Conservation Innovation Grant projects, just under 50 were identified as having a direct relevance to animal air quality in some way. These projects represent a USDA-NRCS investment of just under $20 million. Because each project required at least a 50% match by the grantee, the USDA-NRCS Conservation Innovation Grant program has represented a total investment of approximately $40 million over the past 15 years in demonstrating tools and technologies for addressing air emissions from animal agriculture.

The technologies that have been attempted to be demonstrated in the animal air quality-related Conservation Innovation Grant projects have included various feed management strategies, approaches for reducing emissions from animal pens and housing, and an approach to mortality management. However, the vast majority of animal air quality-related Conservation Innovation Grant projects have focused on air emissions from manure management – primarily looking at anaerobic digestion technologies – and land application of manure. Two projects also developed and enhanced an online tool for assessing livestock and poultry operations for opportunities to address various air emissions.

Future Plans

The 2018 Farm Bill re-authorized the Conservation Innovation Grant Program through 2023 at $25 million per year and allows for on-farm conservation innovation trials. It is anticipated that additional air quality projects will be funded under the current Farm Bill authorization.

Authors

Greg Zwicke, Air Quality Engineer, USDA-NRCS National Air Quality and Atmospheric Change Technology Development Team

greg.zwicke@ftc.usda.gov

Additional Information

More information about the USDA-NRCS Conservation Innovation Grants program is available on the Conservation Innovation Grants website (https://www.nrcs.usda.gov/wps/portal/nrcs/main/national/programs/financial/cig/), including application information and materials, resources for grantees, success stories, and a project search tool.

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2019. Title of presentation. Waste to Worth. Minneapolis, MN. April 22-26, 2019. URL of this page. Accessed on: today’s date.