The application of livestock manure to farm fields has always been an expense for producers. On-farm research plots were assessed in Ohio following application of liquid swine and liquid dairy manure using drag hoses to provide side-dress nitrogen to emerged corn. A six-inch diameter drag hose was used to side-dress corn with swine finishing manure at the V3 stage for four crop seasons. The manure was incorporated at a rate of 6,500 gallons per acre to replace purchased commercial side-dress nitrogen. Plot yield results indicated liquid swine manure produced higher yields when compared to 28% urea ammonium nitrate fertilizer when applied at similar nitrogen levels and the cost savings on purchased fertilizer paid for the manure application cost. The use of liquid manure to sidedress corn can provide a new window of time for manure application in Ohio and apply manure when the nutrients could be utilized by a growing crop.

Purpose

The process of applying liquid swine finishing manure to farm fields represents a significant expense for livestock producers despite the value of the nitrogen, phosphorus and potash contained in the manure. Ohio farmers continue to reduce wheat acreage shifting more of their manure application to the fall application window. The ammonium nitrogen in fall-applied manure is subject to loss before a crop is planted the following season. In the Western Lake Erie Basin of Ohio, an area over three million acres in size, surveys have shown approximate half the livestock manure generated annually is applied in the fall after crops are harvested (Zhang et al., 2015). This allows much of the manure nitrogen to be lost to leaching before the following crop season. Recent research has determined the amount of nitrogen entering Lake Erie influences the toxicity of the hazardous algae blooms.

The ammonium nitrogen in fall applied swine finishing manure can be captured by growing cover crops. A fall cover crop study (Sundermeier, 2010) indicated that an actively growing radish crop reduced soil nitrate nitrogen levels from 21.3 ppm to 6.5 ppm. This prevented the nitrogen from being lost from the field, but only a portion of the organic matter created would mineralize the following crop season to provide nitrogen for a growing crop.

The incorporation of swine finishing manure directly into a growing corn crop with a manure tanker has proven to provide corn yields similar to commercial fertilizer (Arnold et al., 2017). However, Arnold et al. noted soil compaction was a concern with the heavy manure tanker. Using a drag hose to incorporate the manure into emerged corn should overcome the soil compaction concern and allow the corn crop to utilize the available nitrogen in the swine finishing manure. The money saved by not needing to purchase commercial nitrogen to side-dress the corn crop could exceed the cost of the manure application.

What did we do?

This study was designed to determine whether the ammonium nitrogen in liquid swine finishing manure could produce corn yields similar to commercial 28% urea ammonium nitrate (UAN) when the manure was side-dressed on emerged corn using an injection toolbar and soft drag hose (Figure 1).

In each of the four years of this complete block design study, started in 2014, manure was incorporated at a rate of 6,500 gallons per acre to provide approximately 210 pounds per acre of nitrogen. The 28% UAN treatment was applied at approximately 70 gallons per acre to provide 210 pounds of nitrogen per acre. All treatments also received 10 gallons of 28 percent UAN as a row starter fertilizer at planting time to provide approximately 30 pounds of nitrogen. The two treatments (manure and commercial fertilizer) were replicated three times each season.

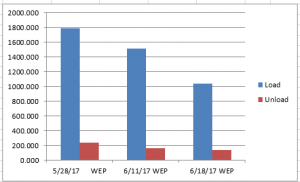

To fit the needs of the commercial manure drag hose operator, each year the corn fields were planted at a 45 degree angle with a 12-row planter using auto-steer. This allowed the commercial manure applicator to stretch the empty manure hose diagonally across the field from one corner to the other at the start of the manure application process (Figure 2).This divided the square field into two triangles and the applicator could apply manure to the entire field without the need of a second tractor to assist in moving the full manure hose. The field had 36 rows (90 feet) of end rows completely around each field allowing the drag hose operator sufficient room to make turns and keep the manure within the boundaries of the field.

The manure came from a 2,450 head swine finishing building with an eight foot deep pit under the animals. This finishing building design is common in Ohio. The manure was pumped through an eight inch diameter hose to the edge of the corn field. A six inch diameter drag hose was pulled across the field during the manure application process.

The corn flattened by the hose typically recovered, i.e. was standing upright, by the following day (Figure 3). The pressure in the hose at the building was more than 200 pounds per square inch. The hose pressure at the toolbar in the field was approximately 30 pounds per square inch. The flow rate was typically between 1,400 and 2,000 gallons per minute depending on the type of pumping equipment used, the diameter of the hoses used, and the distance from the manure storage site to the field during each of the four years.

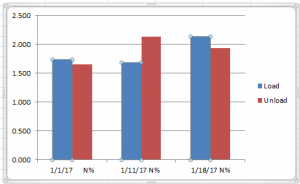

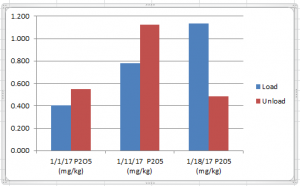

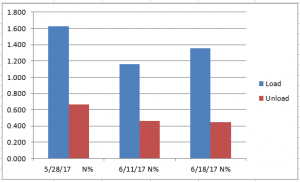

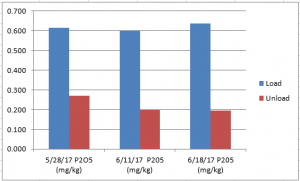

Manure samples were collected and analyzed during the application process each season. The nitrogen, phosphorus and potassium content of the manure was similar each year so application rates were kept the same each season. The analysis indicated the manure contained 32.1 pounds of available nitrogen, 18.0 pounds of P205 and 24.9 of K20 per 1,000 gallons (Table 1).

| Table 1. Average nutrient analysis of swine finishing manure applied. | |

|---|---|

| Nutrient | Pounds per 1,000 gallons |

| Total Nitrogen | 34.3 |

| Ammonium Nitrogen (NH4) | 31.0 |

| Organic Nitrogen | 2.2 |

| Available Nitrogen | 32.1 |

| Phosphorus (P2O5) | 18.0 |

| Potash (K2O) | 24.9 |

The liquid manure application toolbar had rolling coulter manure application units with a wavy coulter tilling up a strip of soil approximately six inches deep and three inches wide. The manure boot applied manure over the tilled strip and the manure was covered by a pair of notched soil closing wheels. Treatments were approximately 1,200 feet long and 30 feet (12 rows) wide. The auto-steer unit used for planting the crop was transferred from the planting tractor to the 275 horsepower tillage tractor, attached to the toolbar and drag hose, for the manure application. The center unit on the toolbar was removed to prevent tillage and manure application to the center row. This enabled the drag hose to ride higher on the soil surface and lessen the scouring of the field. The manure for the center row was diverted to each side so each side received 150% of the normal manure application rate.

In each year of the study manure was not applied to three strips, 12 rows wide, in each field. These strips were fertilized with 28% UAN the same day with the same rate of nitrogen contained in the swine finishing manure. These commercial fertilizer strips did, however, have the drag hose pulled across them as the commercial manure applicator applied manure to all other parts of the fields. Commercial 28% UAN was applied to the ends of the corn fields and edges of the corn fields where the swine manure could not be incorporated.

The fields were no-till or minimum-till and the previous crop each year was soybeans. Plant population counts were conducted each year of the study. The predominant soil type in the fields were Blount Silt loam, end moraine 0 to 2 or 2 to 4% slopes

Soil samples of each of the four fields in this study showed P205 and K20 levels to be in the maintenance range. The Mehlich III P205 levels ranged from 59 to 81 ppm and the K20 levels ranged from 149 ppm to 184 ppm (Table 2).

| Table 2. Annual soil nutrient test results (Mehlich III). | ||||

|---|---|---|---|---|

| Year | ||||

| 2014 | 2015 | 2016 | 2017 | |

| pH | 6.7 | 7.0 | 7.0 | 6.8 |

| Organic Matter (%) | 2.9 | 2.5 | 2.6 | 2.8 |

| P2O5 (ppm) | 66 | 76 | 81 | 59 |

| K2O (ppm) | 161 | 149 | 162 | 184 |

At harvest time each year, yields and moisture data were collected using the combine’s monitor. The monitor was calibrated each season before the manure side-dress plots were harvested. All yields were adjusted for moisture. Yield data were analyzed by ANOVA at the 0.10 probability level.

What we have learned?

Over the four years of this study the incorporated swine finishing manure treatments increased yields when compared to the incorporated 28% UAN treatments by an average of 14.8 bushels per acre (Table 3). This varied from no yield increase the 1st year (2014) to 33 bushel per acre yield increase in 2015, an unusually wet growing season.

| Table 3. Corn yield for treatments comparing nitrogen applied as UAN at planting to side-dressed hog manure. Subscript letters a and b indicate yields that year were statistically different using ANOVA at 0.10 probability level. | |||||

|---|---|---|---|---|---|

|

Yield in Bushels per Acre |

|||||

| Treatments |

2014 |

2015 |

2016 |

2017 |

4-year ave. |

| Incorporated 28 percent UAN |

204 |

121a |

216a |

145a |

171.5 |

| Incorporated swine manure |

204 |

154b |

222b |

165b |

186.3 |

| Least Significant Difference (0.10) |

17.65 |

15.57 |

2.37 |

0.19 |

|

| Coefficient of Variability |

2.45 |

4.74 |

0.62 |

0.39 |

|

The normal accumulated precipitation for the growing season (April 1 through September 30) in this area of Ohio is 23.3 inches. The 2015 season was much wetter than normal, and the 2016 season was drier than normal (Table 4).

| Table 4. Annual planting dates and normal and observed temperature and precipitation data from April 1 through September 30. | ||||

|---|---|---|---|---|

| Year | ||||

| 2014 | 2015 | 2016 | 2017 | |

| Corn planting date | April 25 | May 15 | April 20 | June 1 |

| Normal precipitation (inches) | 23.3 | 23.3 | 23.3 | 23.3 |

| Actual precipitation (inches) | 21.0 | 32.6 | 16.5 | 23.6 |

| Historical average temp (°F) | 65.7 | 65.7 | 65.7 | 65.7 |

| Actual average temp (°F) | 65.3 | 66.2 | 67.2 | 65.9 |

| Average high temp (°F) | 76.8 | 77.6 | 78.8 | 77.4 |

| Average low temp (°F) | 54.8 | 55.8 | 56.7 | 55.4 |

| Total growing degree days | 2,876 | 3,006 | 3,272 | 2,960 |

The application of 6,500 gallons per acre of swine finishing manure supplied approximately 210 pounds per acre of side-dress nitrogen for the corn crop while also supplying sufficient phosphorus and potash for the corn crop and the soybean crop the following year without applying excessive phosphorus (Table 5).

| Table 5. Nutrient balance of swine finishing manure side-dress of corn. Nutrient removal rates are from Vitosh et al., 2003 (Tri-State Soil Fertility Guide). | |||||

|---|---|---|---|---|---|

| Crop | Nutrient removal in pounds per bushel:

200 bushel per acre corn crop followed by a 60 bushel per acre soybean crop |

Available nitrogen (ammonium nitrogen + half the organic nitrogen) | |||

| P205 | K20 | P205 | K20 | N | |

| Corn | 0.37 | 0.27 | 74 | 48 | |

| Soybeans | 0.80 | 1.40 | 54 | 84 | |

| Total nutrients removed | 122 | 138 | |||

| Nutrient content of 6,500 gallons of swine finishing manure applied | 117 | 162 | 210 | ||

| Net nutrients | -5 | +24 | |||

In the first year of this study (2014) the field conditions for manure application were less than ideal. The field was wet and the drag hose scoured more than an inch of soil from the field resulting in some of the V1 corn plants being buried and others being pulled out. This reduced the final plant population of the corn rows next to the drag hose by approximately three thousand plants per acre. In each of the following seasons, when V3 plants were side-dressed, the field conditions were firmer and stand loss from the drag hose was not an issue. This stand reduction may have been the reason why 2014 was the only season in which manure did not yield statistically better than the commercial fertilizer.

The hose dragged across emerged plants caused an obvious lean immediately after the application process. By the following day all the plants were upright again. Stand counts indicated approximately 32,000 plants per acre across both treatments in the 2015, 2016, and 2017 seasons.

The 2015 crop season had the largest difference in crop yields between the treatments. Rainfall that season was more than nine inches above normal (Table 4). Most of this extra rainfall fell during the 35 days following the side-dress treatments. We theorize that the lower yields with the UAN treatment was a result of a greater portion of the commercial fertilizer nitrogen being lost to either denitrification or leaching than the manure nitrogen during that time period.

In the 2017 season the corn was originally planted on April 25. Emergence was so poor as to justify replanting, but field conditions were not firm enough to replant until June. The side-dress applications took place two weeks after planting as the corn grew rapidly with the warm temperatures.

The swine finishing manure application rate of 6,500 gallons per acre provided more than an adequate amount of nitrogen for the corn crop while being just short of balancing phosphorus for the two year needs of a corn-soybean rotation. The amount of potash applied with the manure was 24 pounds more than needed for the crop rotation.

The cost of purchasing 28 percent UAN fertilizer to side-dress corn averaged approximately 40 cents per pound during the four years of this study. At an application rate of 210 pounds per acre the commercial fertilizer side-dress cost was $84.00 per acre (210 pounds * $0.40 per pound). The landowner’s custom cost for applying liquid swine finishing manure was $8.00 per 1,000 gallons or $52.00 per acre (6,500 gallons at $8.00 per 1,000 gallons). The cooperating farmers in this study valued his corn at $3.40 and the 14.8 bushel advantage for the manure treated plots were valued at $50.32 per acre. He also did not need to purchase side-dress nitrogen for the acres where manure was applied, and this saved an additional $84.00 per acre.

Future plans

In this study the application of liquid swine finishing manure at side-dress produced higher corn yields, compared to commercial fertilizer, in three of the four study years. Incorporating liquid swine finishing manure as a side-dress nitrogen source to emerged corn can boost yields, reduce nutrient losses, and give livestock producers another window of time to apply manure to farm fields in-season. The money saved on purchasing commercial side-dress nitrogen can pay for the cost of the manure application to an emerged corn crop.

Ohio State University extension now owns three 12-row manure side-dress toolbars which are being loaned to livestock producers and commercial manure applicators for their use to side-dress emerged corn. We discovered that very few commercial manure applicators in Ohio currently have row-ready tractors and only a small percentage of livestock producers have large enough tractors to pull the drag hoses. Grant monies have also been secured to provide tractors to pull the sidedress toolbars.

There is strong interest from commercial manure applicators to apply manure to corn fields. This practice enables them to apply more total gallons of manure in a year. Current indications are that the application of manure to corn fields will continue to expand in the years ahead as commercial applicators gear up for this practice. Every gallon of manure applied to a growing corn crop in early June is one less gallon likely to be applied during the fall application window.

Authors

Arnold, G. , Field Specialists, Manure Nutrient Management Application, Ohio State University Extension. arnold.2@osu.edu

Custer, S., County Extension Educator, Darke County, Ohio State University

Additional information

Arnold, G. J. (2015). Corn yield results from side-dressing with liquid livestock manure. Journal of the NACAA, 8(2). Retrieved from https://www.nacaa.com/journal/index.php?jid=329

Sundermeier, A. (2010). Nutrient management with cover crops. Journal of the NACAA, 3(1). Retrieved from https://www.nacaa.com/journal/index.php?jid=45

Vitosh, M. L., Johnson, J. W., & Mengel, D. B. (2003). Tri-state Fertilizer Recommendations for Corn, Soybeans, Wheat and Alfalfa. Purdue Extension, Lafayette, IN.

Zhang, W., Wilson, R. S., Burnett, E., Irwin, E. G., & Martin, J. F. (2016). What motivates farmers to apply phosphorus at the “right” time? Survey evidence from the Western Lake Erie Basin. Journal of Great Lakes Research, 42(6), 1343–1356. https://doi.org/10.1016/j.jglr.2016.08.007

Facebook Page: Ohio State University Environmental and Manure Management

Ohio State University Extension Nutrient Stewardship YouTube: https://www.youtube.com/channel/UC7jUsQNGM8fCHjbZUdT9pKw

Acknowledgements

Thanks to Harrod Farms of Rossburg, Ohio for working with Ohio State University Extension on this research project

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2019. Title of presentation. Waste to Worth. Minneapolis, MN. April 22-26, 2019. URL of this page. Accessed on: today’s date.