Due to a technical glitch, the beginning of the recorded presentation was not recorded. Please accept our apologies.

Purpose

Manure management technologies are constantly being developed. But do these technologies meet their intended purpose? How effectively do they perform? Providing impartial evaluations on the effectiveness and longevity of these technologies requires time, finances, and expertise.

Newtrient, with support from a Natural Resources Conservation Service (NRCS) Conservation Innovation Grant (CIG) and a New York Farm Viability Institute Grant, has been evaluating 15 manure-related technologies with a focus on water quality. Through this effort, Newtrient will document the findings from each study to promote the broader adoption of these technologies in livestock manure management. One of the technologies evaluated, N2 Applied, explored the use of plasma treatment to increase nitrogen content in the manure waste stream, while simultaneously reducing ammonia and greenhouse emissions. This presentation will primarily highlight the results from the N2 Applied evaluation.

Figure 1. N2 Applied Demonstration Unit.

What Did We Do?

Newtrient collaborated with Washington State University to develop a technology review protocol. This evaluation process was modeled after the NRCS approach for assessing Waste (Manure) Treatment technologies, as outlined in Conservation Practice Standard 629, Waste Treatment. One of the challenges in reviewing manure management technologies has been obtaining technical third-party evaluations. This protocol established a comprehensive method for reviewing and evaluating these technologies.

For the N2 Applied system, Newtrient contracted with Cornell University as the third-party evaluator. This evaluation compared the nitrogen content and stability of untreated and treated dairy manure over a 15-week period. Both static and flow-through tanks were studied to assess the effectiveness of this treatment process. Liquid samples were analyzed for nutrient content, with a focus on water quality issues, and a limited number of air samples were collected to evaluate greenhouse gas emissions and air quality.

The N2 Applied plasma technology uses electricity to split atmospheric nitrogen and oxygen which then forms into reactive nitrogen gas. This gas is absorbed into the manure waste stream raising the amount of plant available nitrogen while also lowering the pH. This demonstration unit was delivered and operated from a 20 feet long cargo bin.

What Have We Learned?

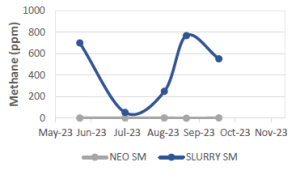

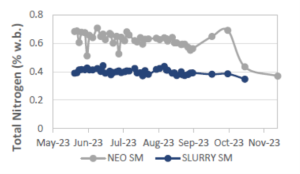

The N2 Applied technology increased the nitrogen content of the dairy manure by more than 50% in the static tanks and nearly 50% in the flow-through tanks. The plasma torch created nitrogen oxides by combining atmospheric nitrogen and oxygen gases. This treatment process lowered the pH to a set point, initially set at 5.5 but later adjusted to 5.0. This lower pH inhibited the microbial production of methane (CH4) and converted more of the nitrogen to ammonium (NH4+) instead of the more volatile ammonia (NH3). The following two figures show the impact of the N2 Applied technology on methane and nitrogen stability for the static tank portion of the study.

The nitrogen content remained stable for more than 4 months, and methane production was significantly reduced through this process. Coarse solid/liquid separation was a key component ensuring the efficient operation of the technology.

For this demonstration unit, the plasma torch used approximately one-half of the energy consumed. The estimated annual electrical cost to operate this unit was $26,800. With the lessons learned from this evaluation, the new commercial unit will have much lower electrical costs.

Future Plans

The N2 Applied system evaluated for this study was a demonstration unit. Based on the lessons learned, a commercial unit is currently being developed, with deployment to the United States expected in late 2025. Once a new unit is installed, another series of studies will be conducted following a similar testing protocol.

For the commercial unit, a critical factor to evaluate will be the long-term stability of the nitrogen-enriched manure. Additionally, it will be important to assess production rates, along with capital and operating costs. Agronomic trials, combined with field emission measurements, will determine the impact on crop yield and air quality once the product is land applied.

Authors

Presenting & Corresponding author

Jeff Porter, Technical Consultant, Newtrient, jeff.porter@newtrient.com

Additional author

Mark Stoermann, Chief Operating Officer, Newtrient

Additional Information

Project and Vendor Information: 2020 NRCS Conservation Innovation Grant – Newtrient

Acknowledgements

Special thanks to the USDA-NRCS Conservation Innovation Grant program and the New York Farm Viability Institute for providing funding to allow for this technology evaluation to take place.

Videos, Slideshows and other media

Webinar Highlighting Evaluation Results: N2 Applied – Insights and Innovation

Newtrient Solutions Catalog: N2 Applied

N2 Applied Homepage: Home – N2 Applied

GEA Manure Enricher: Produce your own sustainable fertilizer | GEA ProManure E2950

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2025. Title of presentation. Waste to Worth. Boise, ID. April 7–11, 2025. URL of this page. Accessed on: today’s date.