Purpose

This study assesses the economic and air quality benefits of using chipped apple orchard wood as a carbon source in a vermifiltration wastewater system. Instead of burning orchard debris, which releases harmful pollutants, the Perca system repurposes it as a substrate for earthworm-microbial wastewater treatment. The study also compares apple wood chips to traditional conifer chips, evaluating their effectiveness and the broader environmental and economic advantages of diverting orchard waste.

What Did We Do?

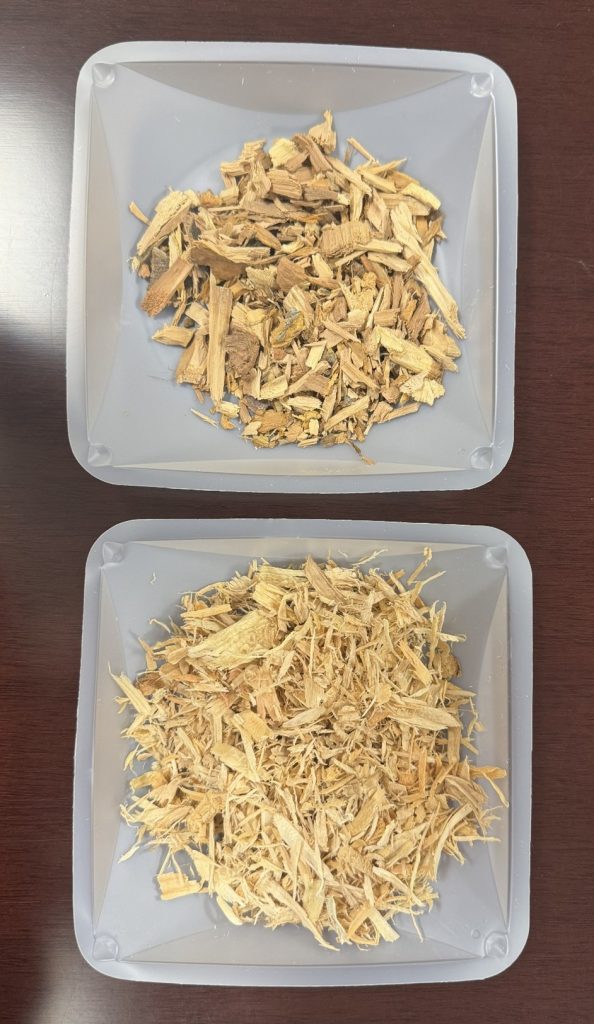

Apple orchard tear-out debris from a local orchard was collected, chipped, and transported for installation as a substrate for the Perca vermifiltration system. Debris was screened to remove foreign materials, chipped to less than ½ inch size, and weighed to calculate tons of usable wood per ton of orchard debris. Data from processing, including chipping costs and labor requirements, were used to assess economic feasibility and air quality impact. In addition, a bench-scale test was conducted to evaluate the efficacy of wastewater treatment by apple orchard chips when compared to the standard conifer chips used in the Perca vermifiltration system. Removal efficiencies of total suspended solids (TSS), biological oxygen demand (BOD), and polychlorinated biphenyls (PCBs) were measured for both substrates.

Market projections for Perca’s vermifiltration system show a compound annual growth rate (CAGR) of 113.45%, reaching 9.57% of the market over the next five years. Calculated market projection estimates over 16,000 tons of orchard debris could be converted into a value-added substrate product rather than burning. This shift could eliminate more than 500 tons of emissions between 2025 and 2029. Economic analysis shows that while chipping costs and wood size restrictions pose challenges for trellised orchards, non-trellised orchards offer better yields and lower costs, with market trends and technology advancements pointing toward broader economic feasibility. Bench-scale tests showed that both apple wood and conifer substrates effectively reduced TSS, BOD, and PCBs by more than 80% in all categories with no significant difference in performance, confirming apple debris works as well as conifer media. These findings demonstrate that apple orchard debris provides an environmentally sustainable alternative to burning, thus contributing to improved air quality, while also an efficient, cost-effective vermifiltration substrate for wastewater treatment.

Future Plans

Ongoing efforts focus on refining the use of apple orchard debris to create a cost-effective, reliable wood chip that matches or exceeds current substrates in reducing conventional and nonconventional wastewater pollutants, while offering an economic alternative to burning. Additionally, strategies are being developed to integrate vermifiltration into regenerative agriculture and circular bioeconomy practices by repurposing spent substrate as a nutrient-rich soil amendment or for soil remediation. This approach transforms agricultural waste into multiple value-added resources, supporting both environmental sustainability and economic viability through continued innovation, collaboration, and stakeholder engagement.

Authors

Presenting & Corresponding author

Sierra J. Smith, Director of Research and Development, Perca, Inc., sierrasmith@perca.net

Additional authors

Joseph S. Neibergs, Professor Extension Economist and Director Western Center for Risk Management Education, Washington State University

George A. Damoff, Chief Science Officer, Perca, Inc.

David A. Elmenhurst, Chief Financial Officer, Perca, Inc.

Additional Information

perca.net

https://ecology.wa.gov/about-us/accountability-transparency/partnerships-committees/boards-councils/agricultural-burning-research-task-force

Acknowledgements

Washington State Department of Ecology for funding and support

Washington State Agricultural Burning Practices & Research Task Force, under direction of the Department of Ecology, for funding and support

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2025. Title of presentation. Waste to Worth. Boise, ID. April 7–11, 2025. URL of this page. Accessed on: today’s date.