Proceedings Home | W2W Home

Purpose

In a global context, the pork industry constitutes a huge economic sector but many producers operate on very thin margins. In addition, pork is one of the largest and most important agricultural industries in North Carolina and the United States but faces a number of challenges in regards to waste management and environmental impacts.On more local scales, swine producers face a number of additional constraints including land availability, waste management options (technical and regulatory), nutrient management costs, profits, risk, and return on investment. In the face of increasingly stringent environmental regulations, decreasing land availability, and higher costs for fertilizer, it is necessary to consider alternative technologies with the potential for improving environmental conditions and creating value added products. Technology assessments generally focus on technical performance as the measure of “utility” or usefulness. Primary physical performance measures such as efficiency, production rate, and capacity, while necessary may not be sufficient for capturing the overall value of a technology. A significant amount of research has evaluated the feasibility of technology adoption based on traditional economic measures but far less research has attempted to “value” environmental performance either at farm-scale or in the larger context (e.g. supply chain response to changes in technology or policy and regulation). Considering response over time, the extent to which environmental and economic policies and regulations positively or negatively affect technology innovation, emission and nutrient management, competitiveness, and productivity, remains largely unknown.

The purpose of this study is to evaluate the environmental and economic tradeoffs between current swine waste management practices in North Carolina and alternative scenarios for future on-farm decision making that include new technologies for waste removal, treatment, and nitrogen recovery. In addition, we begin to understand these economic and environmental tradeoffs in the context of various environmental policy and regulation scenarios for markets of carbon, electricity, and mineral fertilizer.

What did we do?

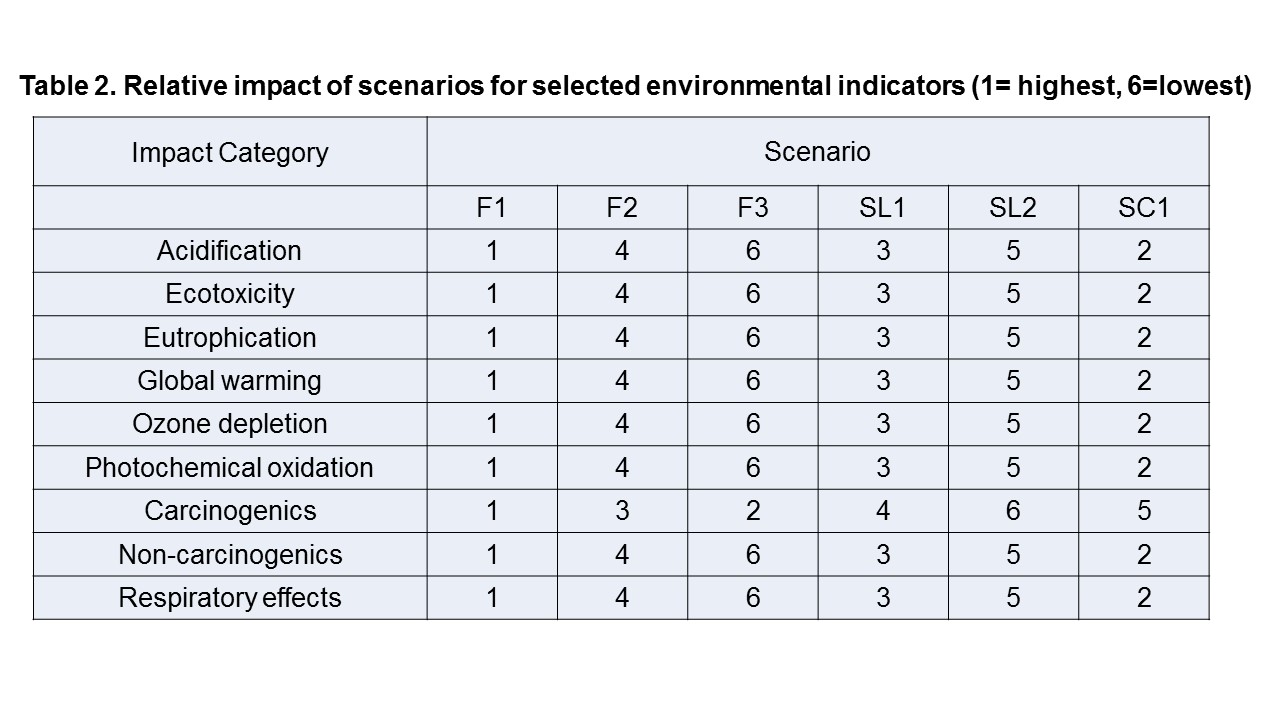

Using waste samples from swine finishing farms in southeastern NC, laboratory and bench scale experiments were conducted to determine the quantity and quality of biogas generation from anaerobic digestion and nitrogen recovery from an ammonia air stripping column. Based on these data as well as information from literature, six trial life cycle assessment scenarios were created to simulate alternatives for annual manure waste management for one finishing barn (3080 head) on the farm. Materials, energy, and emissions were included as available for all system components and processes including but not limited to waste removal from barns (flushing or scraping), treatment (open air lagoon or covered lagoon digester), nitrogen recovery (ammonia air stripping column), and land application (irrigation). A description of the scenarios as well as processes that are included/excluded for each can be found in Table 1. All scenarios were modeled over a one year operational period using a “gate to gate” approach where the mass and energy balance begins and ends on the farm (i.e. production of feed is not included and manure is fully utilized on the farm). It was assumed that each scenario included an existing anaerobic treatment lagoon with manure flushing system (baseline, representative of NC swine farms). In the remaining scenarios, the farm had an option of covering the lagoon and using it as a digester to produce biogas (offsetting natural gas); covering the digester and ammonia air stripping column for nitrogen recovery (offsetting mineral ammonium sulfate); installing a mechanical scraper system in the barn (replaces flushing); and/or different combinations of these. Open LCA, an open source life cycle and sustainability assessment software, was used for inventory analysis and the Tool for Reduction and Assessment of Chemicals and Other Environmental Impacts (TRACI 2.0) was used to characterize environmental impacts to air, water, and land. From Table 2 preliminary results indicate that all scenarios had a similar pattern in terms of impact for the assessed categories. The open air lagoon had the highest overall environmental impact followed by scraping manure with digestion and recovery and scraped slurry digestion with no nutrient recovery. Flushed manure to the digester with nutrient recovery had the lowest overall environmental impact, followed closely by scraped whole slurry to the digester with nutrient recovery.

Using energy and emissions data from the initial life cycle assessment on alternative scenarios for swine waste management systems we have started to characterize the environmental and economic outcomes arising from selected on farm technologies. More specifically we began to examine the regulatory, institutional, and market barriers associated with technology adoption within the swine industry. We provide a theoretical model to support quantification of the change in revenues and expenses that result from changes in three major markets connected to swine production – carbon, electricity, and fertilizer. We examine some of the economic characteristics of environmental benefits associated with changes to farm practices. Finally, we discuss implications for innovation in technology and policy.

What have we learned?

Preliminary results are somewhat mixed and further research is needed to see how sensitive the life cycle assessment inputs and outputs are to system components. While there is a clear indication that covering lagoons, with or without additional nutrient recovery, reduces environmental impact – farm scale systems can be quite expensive and no further determination can be made until a full economic analysis has been conducted. Modeling secondary effects, such as increased ammonia emissions in barns from flush water recirculated from digesters, remains to be included. Besides farm level cost and returns, review of literature has pointed to additional barriers to adoption of reduced environmental impact technologies. Examples of barriers include deficient or non-existent markets for environmental benefits, and various state and federal regulations and policies related to renewable energy, carbon offsets, new farm waste management technology, etc. Solutions such as better cooperation between energy firms, regulatory agencies, and farmers as well as increased financial incentives such as carbon credits, renewable energy credits, net metering options, and enabling delivery of biogas to natural gas pipelines can greatly increase the profitability and implementation of this technology on NC hog farms.

Future Plans

As this is an ongoing multi-disciplinary project, future plans include the expansion of existing data to form a more comprehensive life cycle inventory with options for both new and existing swine farms, which include additional options for waste treatment, nutrient recovery, and land application/fertilizer methods, etc. Energy and emissions data from the life cycle model will continue to be utilized as inputs into a more fully integrated model capable of reflecting the true “cost” and “values” associated with waste management treatment systems. In addition, it is expected that the integrated model will include the flexibility to simulate overall costs and returns for various sizes of operations within the county, region, and if possible state-wide.

Corresponding author, title, and affiliation

Shannon Banner, Graduate Student, North Carolina State University

Corresponding author email

Other authors

Dr. John Classen, Dr. Prince Dugba, Mr. Mark Rice, Dr. Kelly Zering

Acknowledgements

Funding for this project was provided by a grant from Smithfield Swine Production Group

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2017. Title of presentation. Waste to Worth: Spreading Science and Solutions. Cary, NC. April 18-21, 2017. URL of this page. Accessed on: today’s date.