The LPE Learning Center hosted a webcast on Nutrient Planning on Small Farms in June, 2008.

The LPE Learning Center hosted a webcast on Nutrient Planning on Small Farms in June, 2008.

Positive Impacts of Manure

When managed properly, manure can be a valuable resource on a farm. Manure can be a source of nutrients for crop production and improve soil quality. The organic matter present in manure can improve both tilth and water holding capacity of the soil. Livestock and poultry manure is a valuable fertilizer for crop and pasture production. Most farm owners do not realize the value of the manure that is produced on their farms.

Negative Impacts of Manure

When not managed properly, manure can pollute the environment; mainly as ground or surface water pollution due to the nutrients nitrogen (N), phosphorus (P), and carbon (organic matter). In addition manure can lead to air quality concerns, pathogens in water supplies, odors, dust, and the presence of vermin.

Manure Nutrients

Manure nutrients can be beneficial for the soil and plant growth; however, manure application rates should be based on plant growth needs. Excessive manure application to the soil can result in nutrient leaching and increased losses through runoff. In addition, manure contains soluble salts and minerals such as arsenic, copper, and zinc which in excessive amounts may negatively impact the soil quality.

Manure nutrients, (N, P, and organic matter) can be major pollutants in lakes and estuaries as well as rivers. Nitrogen and phosphorus attached to soil particles may reach waterways through surface runoff or wind deposition. Dissolved N and P may leach through the soil, ultimately reaching water bodies. Organic matter can enter water bodies in the form of manure, vegetative matter, or animal carcasses. Waters rich in minerals, organic matter, and nutrients promote a proliferation of plant life, especially algae. This process is called eutrophication. Algae growth and the decomposition of organic matter in water bodies reduces the dissolved oxygen content of the water, which may lead to the death of aquatic life.

Pathogens and Vermin

In addition to the concerns regarding nutrients, pathogens may be present in manure. Some examples of the pathogens are E. coli, Salmonella, and Cryptosporidium parvum. These pathogens can impair water bodies and potentially pose human health risks when manure or contaminated water comes in contact with food sources. Flies and rodents are other manure related concerns on livestock farms. These problems can be minimized by proper design of animal housing and manure storage, and proper handling procedures when turning or moving manure piles.

Air Quality

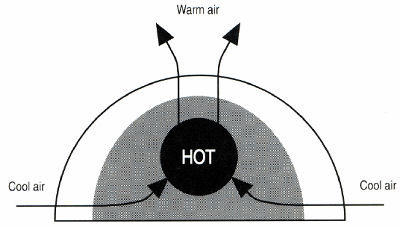

Air quality concerns arise from odors, particulate matter, and aerial pathogens. Ammonia released from manure can result in odor and may react with other compounds in the atmosphere producing particulate matter (PM 2.5) which can affect the environment and public health. There are a variety of other compounds released from manure such as hydrogen sulfide, green house gases (methane and nitrous oxide), and some volatile organic compounds that can also cause air quality concerns. Particulate matter that arises from dust and reaction of ammonia with other compounds in the atmosphere are also a concern.

Why Implement Nutrient Management Planning?

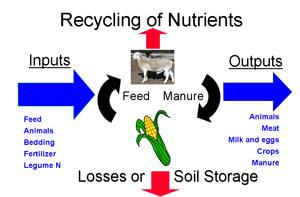

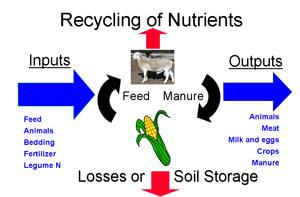

The purpose of nutrient management is to implement practices that permit the efficient use of manure for crop production while protecting potential environmental damage that may be caused by nutrients. Nutrient management planning is a site specific exercise; and, if the recommendations are followed, nutrient losses should be minimal. In general, nutrient management considers the nutrients available on a farm, how best to use them, and the potential impacts of the nutrients on the environment. Factors typically considered in nutrient management planning are: goals of the farming operation as well as any constraints; available farm resources (land, equipment, financial resources); potential critical areas on the farm (sensitive water bodies, neighbor concerns, erosion, manure storage); and nutrient balance analysis (shown in the figure below).

CC2.5 Mike Westendorf

Farm nutrient inputs consist of animals, feed, fertilizer, legume nitrogen, and bedding. Outputs are animals, milk, meat, eggs, manure, and crops. Recycling also occurs on the farm with nutrients moving from feed through livestock, applied to soil, utilized by plants, and back to feed again. The optimal goal (Whole Farm Nutrient Balance) is for the farm to remain in balance between inputs and outputs without losses as runoff or leachate from either the soil or manure. Soil can store some nutrients assuming that the amount of manure applied to the soil is not excessive.

Small Farms are Different than Large Farms

The challenges of managing manure nutrients are different on a small farm than on many larger farms although the principles are similar. Small farms have fewer animals and sometimes several animal species on the same farm. They also may have limited acreage and/or lack equipment for spreading manure. The nutrient management planning section provides information on feeding animals and managing their diets; manure production; basic soil science and soil fertility; and nutrient (manure) management. The section details on- and off-farm use within the context of a nutrient management plan.

The following articles are coming soon!

- Basic soil science and fertility

- Nutrient management on the farm

- Crop utilization

- Nutrient management plans

- Off-farm utilization

- Soil and manure testing

- Record keeping

Additional Resources

Nutrient Management–SIMPLIFIED! by Randall James, Ohio State University Extension

Authors: Jactone Arogo Ogejo, Virginia Polytechnic Institute and State University (Virginia Tech) and Michael Westendorf, Rutgers, The State University of New Jersey