![]() Waste to Worth home | More proceedings….

Waste to Worth home | More proceedings….

Abstract

The use of wet distiller’s grains with solubles (WDGS) in feedlot diets has increased as a result of the growing U.S. ethanol industry. However, few studies have evaluated the use of WDGS in finishing diets based on steam-flaked corn (SFC), the processing method used extensively in the Southern Great Plains. The effects of corn processing method and WDGS on enteric methane (CH4) production, carbon dioxide (CO2) production and energy metabolism were evaluated in two respiration calorimetry studies. In Exp. 1, the effects of corn processing method (SFC or dry rolled corn – DRC) and WDGS inclusion (0 or 30% of diet dry matter- DM) were studied using a 2 x 2 factorial arrangement of treatments and four Jersey steers in a 4 x 4 Latin square design. In Exp. 2, the effects of WDGS inclusion rate (0, 15, 30, or 45% of diet DM) on CH4 and CO2 production were measured in a 4 x 4 Latin square design. Results indicate that cattle consuming SFC-based diets produce less enteric CH4 and retain more energy than cattle fed DRC-based diets. When dietary fat levels were held constant, dietary inclusion of WDGS at 15% of diet DM did not affect enteric CH4 production, WDGS inclusion at 45% of diet DM significantly increased enteric CH4 production and WDGS inclusion at 30% of diet DM had variable effects on enteric CH4 production.

Purpose

Our objectives were to determine the effects of corn processing method and WDGS inclusion rate on enteric methane losses from finishing cattle using respiration calorimetry.

What Did We Do?

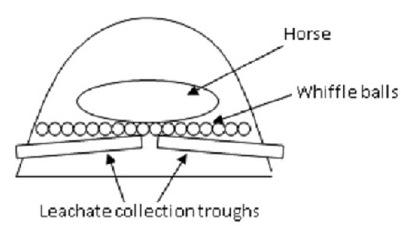

Steer in open circuit respiration calorimetry chamber. |

Eight steers were used in two studies. In each study steers were fed one of four diets at 2 x maintenance energy requirements in a 4 x 4 Latin square design. Each period of the Latin squares included a 16 d adaptation period followed by 5 days of total fecal and urine collection and measurement of gas exchange in respiration chambers. In Experiment 1 dietary treatments consisted of corn processing method (steam flaked -SFC or dry rolled -DRC) and WDGS inclusion rate (0 or 30% of DM). All diets were balanced for ether extract. In Exp. 2, cattle were fed SFC-based diets containing 0, 15, 30 or 45% WDGS (DM basis). The calorimetry system consisted of 4 chambers with an internal volume of 6500 L. Outside air was pulled through chambers using a mass flow system. Gas concentrations were determined using a paramagnetic oxygen analyzer and infrared methane and carbon dioxide analyzers (Sable Systems, Las Vegas, NV) Data were statistically analyzed using the Mixed procedure of SAS.

What Have We Learned?

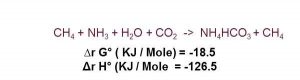

In Exp. 1. no iteractions between grain processing method and WDGS inclusion were detected (P > 0.47). Cattle fed DRC-based diets had greater (P < 0.05) CH4 production (L/steer, L/kg of DMI, % of gross energy intake, and % of digestible energy intake) than cattle fed SFC-based diets probably the result of differences in ruminal fermentation and ruminal pH. Methane losses as a proportion of GE intake (2.47 and 3.04 for SFC and DRC-based diets, respectively) were similar to previous reports and to IPCC (2006) values but were somewhat lower than EPA (2012) values. Grain processing method did not affect CO2 production (13 to 14 Kg/d). WDGS inclusion rate did not affect CH4 or CO2 production. In Exp. 2, CH4 production (L/d) increased quadratically (P = 0.03) and CH4 production as L/kg of DMI and as a proportion of energy intake increased linearly (P < 0.01) with increasing concentrations of WDGS in the diet. Feeding WDGS did not affect (P > 0.23) total CO2 production. Conclucions: Our results indicate that cattle consuming DRC-based finishing diets produce approximately 20% more enteric CH4 than cattle fed SFC-based diets. When WDGS comprised 30% or less of the diet and diets were similar in total fat content, feeding WDGS had little effect on enteric CH4 but when fed at higher inclusion rates enteric CH4 production was increased by approximately 40%.

Future Plans

Over 80% of the enteric methane emissions of the U.S. beef cattle herd are produced by cows, calves, and yearling on pasture. Therefore, additional research will study the effects of supplementation strategies and forage quality on enteric methane production by cattle.

Authors

N. Andy Cole; Research Animal Scientist/Research Leader; USDA-ARS-CPRL, Bushland, TX andy.cole@ars.usda.gov

Kristin E. Hales, Research Animal Scientist, USDA-ARS-MARC, Clay Center, NE

Richard W. Todd, Research Soil Scientist, USDA-ARS-CPRL, Bushland, TX

Ken Casey, Associate Professor, Texas AgriLife Research, Amarillo, TX

Jim C. MacDonald, Associate Professor, Dept. of Animal Science, Univ. of NE, Lincoln

Additional Information

Hales, K. E. , N. A. Cole, and J. C. MacDonald. 2013. Effects of increasing concentrations of wet distillers grains with solubles in steam-flaked corn-based diets on energy metabolism, carbon-nitrogen balance, and methane emissions of cattle. J. Anim. Sci. (in press)

Hales, K. E. , N. A. Cole, and J. C. MacDonald. 2012. Effects of corn processing method and dietary inclusion of wet distillers grains with solubles on energy metabolism, carbon-nitrogen balance, and methane emissions of cattle. J. Anim. Sci. 90:3174-3185.

Acknowledgements

Mention of trade names or commercial products in this article is solely for the purpose of providing specific information and does not imply recommendation or endorsement by the USDA. USDA is an equal opportunity provider and employer.

We wish to thank USDA-NIFA for partial funding through Project # TS-2006-06009 entitled “Air Quality: Odor, Dust and Gaseous Emissions from Concentrated Animal Feeding Operations in the Southern Great Plains”

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2013. Title of presentation. Waste to Worth: Spreading Science and Solutions. Denver, CO. April 1-5, 2013. URL of this page. Accessed on: today’s date.