Waste storage pits and indoor tanks are generally under-floor inside the dairy, swine (and sometimes poultry) housing. Waste storage ponds and above ground storage tanks are fenced and posted to keep young children, livestock, and other unauthorized visitors away. Pond banks are seeded or sodded with a good grass cover to prevent soil erosion and mowed regularly to control grass and weed growth.

Recommendations for siting, design, and construction of manure storage units are provided in ASABE Technical Library EP393.3 Manure Storages. These recommendations are for both earthen and fabricated structures.

Storage Volume

Storage volume considerations include daily animal manure and related wash/flush water inputs. Dairy cattle generally generate larger manure volumes per live weight than swine, beef, or poultry. A mature dairy cow weighing 1,400 pounds can generate around 14 gallons (about 120 pounds or 1.9 cubic feet) of feces and urine each day with an average as-excreted solids content of around 12 percent.

The total excrement for cows housed in freestall total confinement, along with milking wash wastes would bring the total to more than 2.5 cubic feet per cow per day. For 100 cows, this is nearly 9 tons and 9+ cubic yards of manure per day. For cows on pasture part-time, manure handling and storage needs would be less and in direct proportion to actual confinement time. A 100-cow herd on half-time pasture would accumulate nearly 5 cubic yards (4.5 tons) of manure per day in confinement, including milk wash wastes. This daily manure volume for the confinement operation is multiplied by the planned storage period days to get the manure storage volume for the planned storage period.

Outdoor Storage Pond Volume

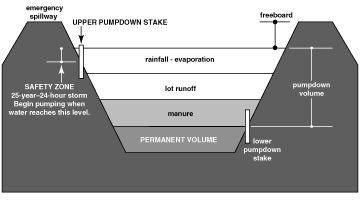

Outside storage pond or uncovered tank volume must also include expected rainfall minus evaporation from the storage surface. In high rainfall areas like the Southeastern US this could be 12 to 14 inches annually. In all geographical locations, this is based on the planned storage interval worst case and on local rainfall and evaporation figures. Volume must also include space for the 25-year-24-hour rainstorm event and any resulting watershed runoff into the pond. Roof and other rainfall runoff may or may not be included, depending on whether dilution water is needed for irrigation or not needed for tank wagon application of dairy waste.

In addition, the volume of the storage pond should also include an allowance of at least 1 foot of freeboard above expected full level for overflow cushion protection and an allowance of at least 2 feet of depth on the bottom of the pond for materials not removed during the normal agitation-pumpout procedure. Storage pond pumpout must be carried out within the planned storage period. Pumpout should be started in time to insure that space is available to hold the 25-year-24-hour rainstorm.

Irrigating with Animal Waste

Waste irrigation equipment or tank wagons and specially designed pumps must be available, with tractors large enough to handle the horsepower requirements. Both agitation before pumpout and manure solids handling pumps matched to either the slurry irrigation system or “honey wagon” transfer tank are critical to successful waste storage pond pumpout. See the figure below for a cross section of a waste storage pond. Note the upper pumpdown stake. Pumping should begin when water reaches this level.

Irrigating with slurry calls for special equipment designed to handle both the high solids content and high fertilizer content of the waste.

Related Web Pages

- Liquid Manure Storage Treatment Options, Including Lagoons

- Role of Solid Liquid Separation in Manure Storage

- Earthen Manure Containment Structures

- Liquid Manure Treatment Lagoons

Recommended Reading About Manure Storage Ponds, Pits and Tanks

- Livestock and Poultry Environmental Stewardship Curriculum LPES Lesson 20: Planning and Evaluation of Manure Storage

- Livestock and Poultry Environmental Stewardship Curriculum LPES Lesson 24: Operation and Maintenance of Manure Storage Facilities

- American Society of Agricultural and Biological Engineers On-Line Technical Library, ASABE Technical Library EP393.3 Manure Storages

Research Summaries

- National Center for Manure and Animal Waste Management white paper summary, Closure of Earthen Manure Structures–Including Basins, Holding Ponds and Lagoons published by North Carolina State University. The full white paper can be ordered from MWPS, Iowa State University.

Page Managers: Ted Tyson, Auburn University, tysontw@auburn.edu and Saqib Mukhtar, Texas A&M University, mukhtar@tamu.edu .