The typical dairy farm uses a large amount of energy during milking activities. This is due to the frequency of milking and the energy intensive nature of harvesting milk, keeping it cool, and cleaning the equipment with hot water. Renewable energy systems generally become more economically efficient as the amount of energy used increases, making dairy farms a great place to incorporate renewable energy.

Dairy farms have not typically been set up with energy efficiency in mind and often use relatively expensive fuel sources like heating oil or propane to heat water. One of the difficulties encountered with renewable energy systems is the intermittent generation of wind and solar energy, whereas the energy load on a dairy farm is very consistent since cows are typically milked twice or three times every day (very large dairies may milk continuously). An efficient way to store energy has long been sought to tie energy production and consumption together. A dairy farm’s need for both electricity and heat provides an ideal situation to generate electrical energy on-site to meet current electrical load requirements, displace conventional thermal fuels with electrical energy, and evaluate thermal storage as a solution to the time shifting of wind and solar electrical generation.

What did we do?

The dairy operation at the University of Minnesota West Central Research and Outreach Center in Morris milks between 200 and 275 cows twice daily and is representative of a mid-size Minnesota dairy farm. The cows are split almost evenly between a conventional and a certified organic grazing herd, and all cows spend the winter outside in lots near the milking parlor. The existing dairy equipment is typical for similarly sized dairy farms and includes none of the commonly recommended energy efficiency enhancements such as a plate cooler, refrigeration heat recovery, or variable frequency drives for pump motors. The WCROC dairy provides an ideal testing opportunity to evaluate and demonstrate the effect of on-site renewable energy generation and energy efficient upgrades on fossil fuel consumption and greenhouse gas emissions (Figure 1).

A data logger was installed in the utility room of the milking parlor in August 2013 to monitor 18 individual electric loads, 12 water flow rates, 13 water temperatures, and two air temperatures. Average values were recorded every 10 minutes for the last 4 years. The milking parlor has gas and electric meters that measure the total consumption of natural gas and electricity within the parlor. The data helped us evaluate energy and water usage of various milking appliances. Some small energy loads were not measured in unused parts of the barn, or for equipment not directly related to the milking operation. These small and miscellaneous loads were estimated by subtracting monitored energy use from the total energy use.

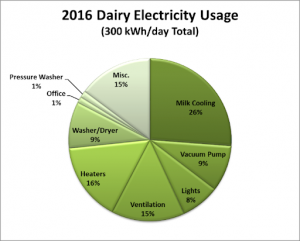

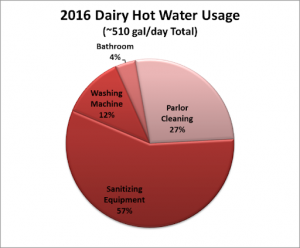

Baseline measurements were collected at the WCROC dairy and overall, the milking parlor currently consumes about 250 to 400 kWh in electricity and uses between 1,300 and 1,500 gallons of water per day (Figures 2 and 3). The parlor currently uses about 110,000 kWh per year (440 kWh per cow per day) in electricity and 4,500 therms per year in natural gas. A majority of the electricity (26 percent) is used for cooling milk , with ventilation, fans and heaters utilizing 16 percent. The dairy uses about 600 gallons of hot water per day, with a majority used for cleaning and sanitizing milking equipment (57%), followed closely by cleaning the milking parlor (27%). Energy and water usage fluctuates throughout the year; the dairy calves 40 percent of the cows from September to December and 60 percent from March to May. Therefore, water and energy use escalates dramatically during April.

The first energy efficiency upgrade was the installation of a variable frequency drive for the vacuum pump in September 2013. Prior to the upgrade, the vacuum pump used 55 to 65 kWh per day. Following installation, electrical consumption by the vacuum pump decreased by 75% to just 12 kWh per day. This data provides a vivid example of the significant energy savings that can be achieved with relatively simple upgrades.

Because the dairy operates both organic and conventional systems, two bulk tank compressors are used: one scroll and one reciprocating. The scroll compressor is the newest and uses 15 kWh per day versus 40 kWh per day for the reciprocating compressor. Based on milk production, the scroll compressor costs $0.73 per kWh per cwt. versus $1.08 per kWh per cwt. for the reciprocating compressor, indicating that the scroll compressor is more efficient. In terms of fossil fuel consumption, milk harvesting consumed more energy than feeding and maintenance.

During the fall of 2016, a TenKSolar Reflect XTG 50 kW DC array was installed. The annual production from this solar PV system was projected to be 70,000 kWh. At a total cost of $138,000 ($2.77/W) for the solar system, a 19.7-year simple payback without incentives was predicted. Adding the “Made in Minnesota” incentives would reduce the payback period to 8.6 years.

In 2017, two 10-kW VT10 wind turbines from Ventera were installed. These turbines are a three blade, downwind turbine model, each with an annual predicted generation of 22,400 kWh. The wind system cost was $156,800 ($78,400 per tower) with a 35-year simple payback without incentives. With the 30% federal credit, each turbine would have a 24.5-year payback.

What we have learned?

Our study suggests that fossil energy use per unit of milk could be greatly reduced by replacing older equipment with new, more efficient technology or substituting renewable sources of energy into the milk harvesting process. To improve energy efficiency, begin with an audit to gather data and identify energy-saving opportunities. Some energy efficiency options that may be installed on dairy farms include refrigeration heat recovery, variable frequency drives, plate coolers, and more efficient lighting and fans. A majority of these upgrades have immediate to two- to five-year paybacks. Make all electrical loads as efficient as possible, yet practical. Consider converting all thermal loads to electricity by the use of heat pumps that allow for cooling of milk. In the future, we have plans to harvest energy from our manure lagoon and store electricity as heat by use of heat pumps. Renewable energy options also can improve energy efficiency.

Future Plans

We will continue to monitor the WCROC dairy and make renewable energy upgrades. We have begun monitoring the two 10-kW wind turbines, and installed a new 30-kW solar array in the WCROC pastures for renewable energy production. Additionally, we will evaluate the cow cooling potential of solar systems in the grazing dairy system at the WCROC. This study is the first step toward converting fossil fuel-based vehicles used in dairy farms to clean and locally produced energy. The knowledge and information generated will be disseminated to agricultural producers, energy professionals, students, and other stakeholders.

Authors

Brad Heins, Associate Professor, Dairy Management, hein0106@umn.edu

Mike Reese, Director of Renewable Energy

Eric Buchanan, Renewable Energy Scientist

Mickey Cotter, Renewable Energy Junior Scientist

Kirsten Sharpe, Research Assistant, Dairy Management

Additional information

We have developed a Dairy Energy Efficiency Decision Tool to help provide producers a quick way to estimate possible energy and costs savings from equipment efficiency upgrades. The tool can be used to quickly see what areas of a dairy operation may provide the best return on investment. Furthermore, we have developed a U of MN Guidebook for Optimizing Energy Systems for Midwest Dairy Production. This guidebook provides additional information about the topics that were discussed in this article, as well as the decision tool. More information may be found at https://wcroc.cfans.umn.edu/energy-dairy

Acknowledgements

To complete our goals, we have secured grants from the University of Minnesota Initiative for Renewable Energy and the Environment (IREE), the Minnesota Rapid Agricultural Response Fund, and the Xcel Energy RDF Fund.

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2019. Title of presentation. Waste to Worth. Minneapolis, MN. April 22-26, 2019. URL of this page. Accessed on: today’s date.