Proceedings Home | W2W Home

Purpose

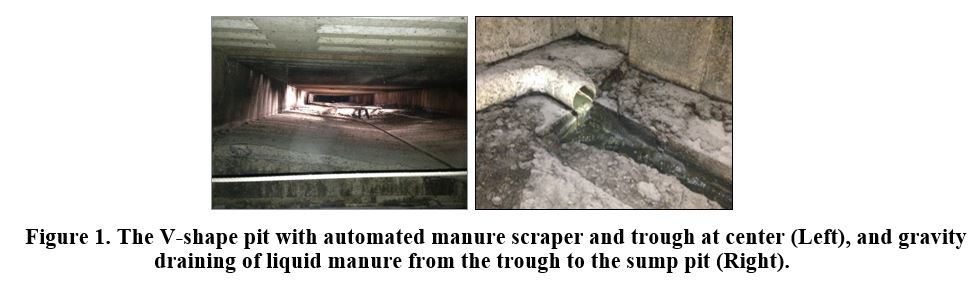

This paper documents an on-going evaluation of an existing, full-scale solid/liquid separator barn for the potential of improved manure nutrient conservation and management, water recycling, including cost and handling implications. The barn has V-shaped pit floor to drain liquid manure, and automated scrapers to collect solid manure frequently. The finishing barn was built to improve indoor air quality, and improve manure handling and land application of nutrients.

What did we do?

- Collected monthly manure samples (both solid and liquid manure samples) at the commercial barn starting in September, 2016. The collected samples were analyzed for important manure nutrients, pH, and moisture content.

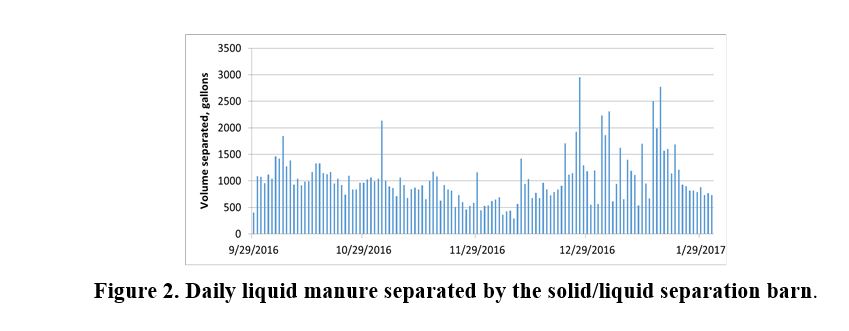

- Monitored daily liquid manure production by measuring the water level fluctuation in the receiving pit, using a liquid pressure data logger (U20L-04, HOBO Water Level, Onset Computer Corporation, Bourne, MA). A new pressure gauge with two sensors was then added to allow simultaneous measurement of atmospheric pressure to improve accuracy.

- Monitored accumulation of solid manure, by measuring dimensions of the manure pile during each sampling event. A camera was purchased and installed at the storage shed to take hourly photos of the storage pile.

- Conducted filtration pilot tests using water and salty water and a bench-scale cross-flow treatment system, capable of various filtration options including reverse osmosis.

- Conducted settling/pre-treatment tests of the liquid manure samples, by storing liquid manure in individual jars and periodically characterizing settling of manure solids and duration needed before the high-pressure filtration.

What have we learned?

Battery-operated gauges were able to closely monitor the water level, liquid manure flow, and operation of the pump, and the dual-sensor gauge was much easier in data analysis and downloading. The daily liquid manure level fluctuated significantly during the first six months of monitoring, which could be due to differences in animal size and occurrence of barn washing. Solid manure samples collected in the current project had higher moisture contents than the four samples collected in 2014, meaning the solid/liquid separation barn was not as effective in separating solids and liquids as in 2014. But, the settling tests suggest a settling basin could be designed to pre-treat the liquid manure stream before a water extraction process.

Future Plan

A year’s worth of data will be collected, and manure nutrient flows of the solid and liquid portions will be quantified. The team will also characterize and compare the barn and management costs (relative to a typical deep-pit barn), practicality, and costs of the use of filtration and reverse osmosis. Will provide pork producers information on potential for the solid/liquid separation barn and filtration process to improve nutrient management, land application, and water conservation.

Corresponding author, title, and affiliation

Teng Lim, Associate Professor, Agricultural Systems Management, University of Missouri

Other authors

Joshua Brown, Graduate Research Assistant; and Joseph M. Zulovich, Assistant Professor; Agricultural Systems Management, University of Missouri.

Additional information

Teng Lim, limt@missouri.edu

Acknowledgements

The authors would like to thank the National Pork Board and University of Missouri Extension for financial support, and the farm management team for their help with the project.