Proceedings Home | W2W Home

Purpose

Long term and significant accumulation of sludge in anaerobic swine lagoons reduces its storage volume and ability to treat waste. Usually, excess accumulation of lagoon sludge is removed using pump or dredge. The dredged sludge is then land applied at agronomic rates according to its nutrient content.

The accumulation of phosphorus (P) in the sludge requires the largest area of land application based on crop agronomic requirements. Therefore, nutrient management plans may limit application to crop or pastureland near the animal facility to avoid P build up in excess of soil and crop assimilative capacities. Although dewatered sludge can be moved off the farm, transportation becomes less economical with increasing distances. An option is to extract and recover P in a concentrated form for its economical transfer to P-deficient croplands, for use as fertilizer.

What did we do?

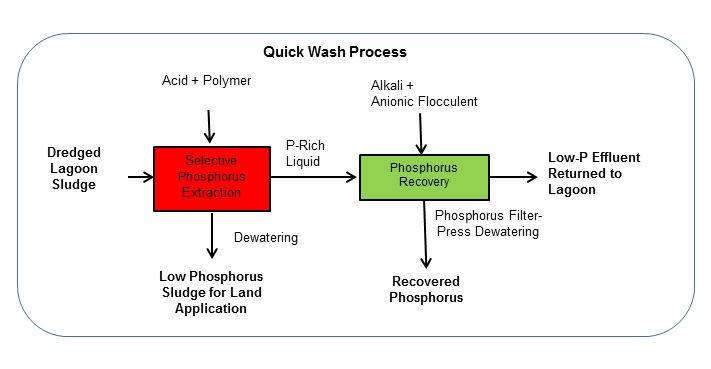

A patented treatment process, called Quick Wash (QW), developed by USDA-ARS for extraction and recovery of P from animal manure solids was tested for recovery of P from anaerobic swine lagoon sludge. With the QW process, P was extracted in solution from dredged sludge by mixing with sulfuric acid prior to dewatering using polymer enhanced mechanical solid-liquid separation. After that, P was recovered by addition of liquid lime and an anionic flocculent to the separated liquid extract to form a calcium-containing P precipitate. The QW process generated two solid products: 1) sludge solids low in P; and 2) a concentrated P material.

P was extracted in solution from dredged sludge by mixing with sulfuric acid prior to dewatering using polymer enhanced mechanical solid-liquid separation. After that, P was recovered by addition of liquid lime and an anionic flocculent to the separated liquid extract to form a calcium-containing P precipitate. The QW process generated two solid products: 1) sludge solids low in P; and 2) a concentrated P material.

What have we learned?

While most of the nitrogen and carbon was left in the washed sludge solids, the QW process extracted and recovered as much as 90 % of the P from sludge. From results of a pilot field test, the P grade of the recovered phosphate was in the range of 24.0% – 30.5 % P2O5. The inclusion of this process in a lagoon sludge management plan offers producers an opportunity to locally land-apply the low-P sludge as a carbon-rich soil amendment and recover P as a valuable product for export from the farm.

Future Plans

USDA granted an exclusive license of the invention to Renewable Nutrients, LLC (Pinehurst, NC) to commercialize in the U.S the process for P recovery from animal and municipal waste streams. Renewable Nutrients is developping commercialization plans for the Quick Wash process that will include the operating and equipment costs of phosphorus recovery from dredged lagoon sludge.

Corresponding author, title, and affiliation

Ariel A. Szogi, Research Leader, USDA-ARS Coastal Plains Soil, Water, and Plant Research Center, Florence, SC.

Corresponding author email

Other authors

Matias B. Vanotti; and Paul D. Shumaker – USDA-ARS Coastal Plains Soil, Water, and Plant Research Center, Florence, SC.

Additional information

https://www.renewablenutrients.com/

Acknowledgements

This work is part of USDA-ARS National Program 212; ARS Project 6082-12630-001-00D “Improvement of Soil Management Practices and Manure Treatment/Handling Systems of the Southern Coastal Plain.”