Purpose?

There is major interest from producers and the public in implementing best control technologies that would abate ammonia (NH3) emissions from confined livestock and poultry operations by capturing and recovering the nitrogen (NH3-N).

What did we do?

In this study, we continued investigating development of gas-permeable membrane modules as components of new processes to capture and recover gaseous ammonia inside poultry houses, composting facilities, and other livestock installations. The overall research objective was to improve poultry houses with the introduction of nitrogen emission capture technology. There were two milestones during the initial phase of the study: 1) to test ammonia recovery with gas-permeable membranes in a bench system using Maryland’s poultry manure; and 2) to construct and install a pilot ammonia recovery system at the UMES Poultry Research facility.

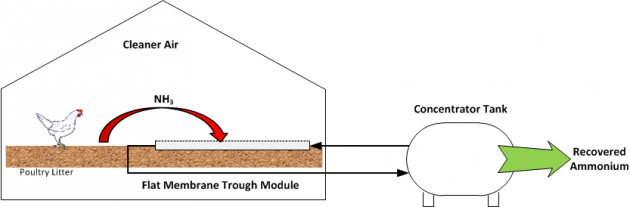

Figure 1. System for the recovery of gaseous ammonia from poultry waste using gas-permeable membrane module.

What have we learned?

The prototype ammonia recovery bench system using gas-permeable modules was moved from ARS-Florence to ARS-BARC in Sept. 2013 and tested during three consecutives runs using turkey and chicken manure mixes. The bench unit had two chambers: one was used with recirculating acid solution (1 N H2SO4) and the other was a control that used recirculating water. The control, which used water as the capture solution, was very effective at recovering the ammonia. This finding may lead to more economical ammonia recovery systems in the future.

Figure 2. Prototype ammonia recovery system using gas-permeable modules.

Two pilot ammonia recovery systems using gas-permeable membranes were constructed at ARS-Florence and installed at the UMES poultry research facility in June 2014. One ammonia recovery module was developed using flat membranes mounted on troughs. The other module was developed using tubular gas-permeable membranes. The recovery manifolds were placed inside the experimental barns (400 chickens) hanging from the roof and close to the litter. Both systems were installed with the ammonia concentrator tanks outside the barns. They were tested continuously for four months without chickens in the barns. The first flock of birds was placed in the facility Feb. 2015 and also in a control facility without the ammonia recovery modules. The installed modules will demonstrate the ammonia recovery and the potential poultry production benefits from cleaner air.

Figure 3. Pilot ammonia recovery systems installed in a chicken barn at UMES Poultry Research Facility. At left is a recovery module that uses tubular gas-permeable membranes. At right is a recovery module that uses flat gas-permeable membranes.

Future plans?

The N recovery modules are being demonstrated at the University of Maryland Eastern Shore’s Poultry Research facility.

USDA seeks a commercial partner to develop and market this invention (Gaseous ammonia removal system. US Patent 8,906,332 B2, issued Dec. 9, 2014). http://www.ars.usda.gov/business/docs.htm?docid=763&page=5

Authors

Matias Vanotti, USDA-ARS, Florence, South Carolina matias.vanotti@ars.usda.gov

Vanotti, M.B.1; Millner, P.D.2 ;Sanchez Bascones, M.3 ;Szogi, A.A.1; Brigman, P.W.1; Buabeng, F.4; Timmons, J.4 ; Hashem, F.M.4

1USDA-ARS Coastal Plains Soil Water and Plant Research Center, Florence, SC, USA

2USDA-ARS Environmental Microbial and Food Safety, Beltsville, MD, USA

3University of Valladolid, School of Agric. Engineering, Palencia, Spain

4University of Maryland Eastern Shore, Dept. of Agriculture, Food and Resource Sciences, Princess Anne, MD, USA

Additional information

Szogi, A.A., Vanotti, M.B., and Rothrock, M.J. 2014. Gaseous ammonia removal system. US Patent 8,906,332 B2, issued Dec. 9, 2014. US Patent and Trademark Office, Washington, DC.

Rothrock Jr, M.J., Szogi, A.A., Vanotti, M.B. 2013. Recovery of ammonia from poultry litter using flat gas permeable membranes. J. of Waste Management. 33:1531-1538

“Recovery of ammonia with gas permeable membranes” research update at USDA-ARS-CPSWPRC website http://www.ars.usda.gov/Research/docs.htm?docid=22883#ammonia

Acknowledgements

We acknowledge NIFA Project “Novel Integration of Solar Heating with Electricity Generation Technology and Biofiltered Poultry Litter Biofertilizer Production System” and ARS Project 6657-13630-001-00D “Innovative Animal Manure Treatment Technologies for Enhanced Environmental Quality”. Funding by University of Valladolid/Banco Santander for participation of Dr. Sanchez Bascones as Visiting Scientist is also acknowledged.

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2015. Title of presentation. Waste to Worth: Spreading Science and Solutions. Seattle, WA. March 31-April 3, 2015. URL of this page. Accessed on: today’s date.