Why Compare Liquid and Slurry Systems for Pig Production?

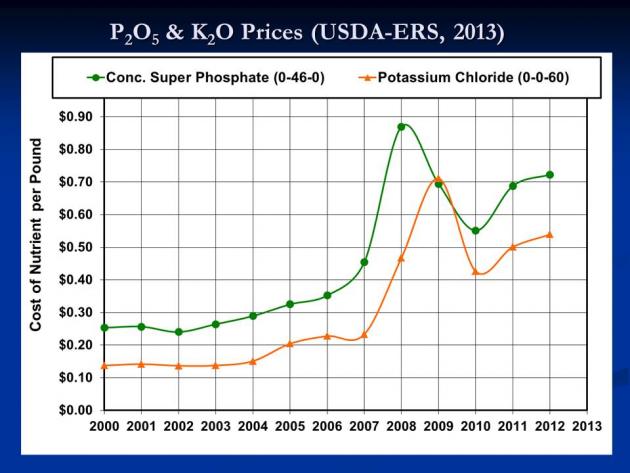

Since 2000 the cost of fertilizer has more than doubled. According to information provided by the USDA Economic Research Service (2013), the national average price per pound of N has increased between 2000 and 2012 by a factor of 2.6. Over the same time period, phosphate price increased by a factor of 2.8, and potassium price increased by a factor of 4.0. As a result, fertilizer costs now contribute 30% to 40% of the annual variable costs to grow many cereal grains.  During the same time period environmental regulations have greatly decreased the construction of swine finishing facilities that use liquid manure handling systems that require the use of a lagoon or storage pond. In response to these economic and regulatory realities, some swine production companies are considering the use of deep pit slurry systems instead of an outdoor lagoon or storage. Benefits of the deep pit slurry system include the exclusion of rainfall, reduction in storage visibility, and conservation of valuable major plant nutrients (N, P, K) for the purpose of reducing production costs for feed grains. The objective of this presentation is to compare the fertilizer value of the manure produced from swine finishing barns that use a liquid manure handling with a treatment lagoon, and swine finishing barns that store manure below slotted floors in pits.

During the same time period environmental regulations have greatly decreased the construction of swine finishing facilities that use liquid manure handling systems that require the use of a lagoon or storage pond. In response to these economic and regulatory realities, some swine production companies are considering the use of deep pit slurry systems instead of an outdoor lagoon or storage. Benefits of the deep pit slurry system include the exclusion of rainfall, reduction in storage visibility, and conservation of valuable major plant nutrients (N, P, K) for the purpose of reducing production costs for feed grains. The objective of this presentation is to compare the fertilizer value of the manure produced from swine finishing barns that use a liquid manure handling with a treatment lagoon, and swine finishing barns that store manure below slotted floors in pits.

What did we do?

What did we do?

Plant nutrient content and volume data were collected from a swine finishing farm that used a lagoon treatment system. The system was designed to provide storage of manure, anaerobic treatment of volatile solids, and storage for sludge for 3520 pigs. Treated lagoon surface water (total solids = 0.5%) was recycled through the four buildings to provide water to remove manure from the building using a pull-plug, pit-recharge design. Lagoon surface water was applied to nearby cropland annually to provide all major plant nutrients using traveling gun irrigation. Data were also collected concerning the plant nutrient content of lagoon sludge, and sludge volumes were estimated using the ASABE Standard (2011).

The realized value of swine manure was calculated for using lagoon water, and sludge to provide all or a portion of the N, P2O5, K2O used by corn based on typical crop needs. Only the portion of plant nutrients that met the recommendations was assigned value. No value was assigned to major plant nutrients applied in excess of plant uptake. The value was assigned based on price data obtained from USDA-ERS (2013). The prices used were $0.71/lb of N, $0.69/lb of P2O5, and $0.50/lb of K2O.

The realized value of swine manure was calculated for using lagoon water, and sludge to provide all or a portion of the N, P2O5, K2O used by corn based on typical crop needs. Only the portion of plant nutrients that met the recommendations was assigned value. No value was assigned to major plant nutrients applied in excess of plant uptake. The value was assigned based on price data obtained from USDA-ERS (2013). The prices used were $0.71/lb of N, $0.69/lb of P2O5, and $0.50/lb of K2O.

Two application rates were calculated for lagoon water. The first rate was to provide the N needs for corn and the second was to provide the P2O5 needs of the crop. The pounds of N, P2O5, and K2O applied per acre were determined and the value of the nutrients that met the fertilization rates was calculated.

Lagoon sludge (total solids = 10%) contained 4 times as much P2O5 as plant available N (PAN) per 1000 gallons (47.3 lb P2O5/1,000 gal vs 11.7 lb PAN/1,000 gal). Therefore, the only sludge application rate used was the rate needed to meet the fertilizer recommendation for P2O5. The realized value of the sludge was determined in the same way as for lagoon water.

When lagoon water was applied to supply the N needs of one field, and sludge was applied to meet the P2O5 needs of another field the realized value of swine manure was $5.69 per hog-space per year. Application of lagoon water and sludge to meet the P2O5 needs of corn increased the annual value of manure to $6.64 per hog-space.

When lagoon water was applied to supply the N needs of one field, and sludge was applied to meet the P2O5 needs of another field the realized value of swine manure was $5.69 per hog-space per year. Application of lagoon water and sludge to meet the P2O5 needs of corn increased the annual value of manure to $6.64 per hog-space.

The analysis was repeated for the same size farm using volume and nutrient data for deep pit barns that provided 1 year of storage for swine slurry (total solids = 7.5%). The realized economic value of deep pit slurry was also calculated based on application of slurry, using direct injection, to meet the N and P2O5 needs of corn with the same price assumptions as for the lagoon system. The results indicated that spreading deep pit slurry based on the agronomic rate for N provided a realized manure value of $24.35/hog-space/yr. Application of slurry based on the agronomic rate for P2O5 yielded a manure value of $28.95/hog-space/year.

What have we learned?

Treatment lagoons were originally designed to provide treated water used to remove manure from flush or pit-recharge swine buildings. However, little consideration was given to the value of the N lost or the value of P and K. Essentially, lagoons provided the treatment needed for recycled flush or pit-recharge systems, but they wasted nitrogen that could be used to off-set fertilizer costs.

Over the last decade, fertilizer prices have increased greatly, and continue to fluctuate. As a result, the nutrients lost by manure treatment are now viewed as a valuable input for production of feed grains.

Using a deep pit barn eliminated the need for manure treatment and allowed plant nutrients to be stored until needed. It was estimated that a deep pit slurry system would allow a producer to increase nutrient value per hog-space by a factor of 4.3 from $6.68 to $28.95/hog-space per year. On a 4-house farm that provided housing for 3520 hogs the annual manure value may be as high as $101,920 per year.

Future Plans

The results from this study are being used to develop extension programs for swine producers. Information is being used to help plan farms and to encourage integration of swine and feed grain production.

Author

John P. Chastain, Ph.D., Professor and Extension Agricultural Engineer, Clemson University jchstn@clemson.edu

Additional information

Reference Cited

ASABE (2011). ANSI/ASAE EP403.4 FEB2011 Design of Anaerobic Lagooons for Animal Waste Management. In ASABE STANDARDS. ASABE, 2950 Niles Rd., St. Joseph, MI 49085-9659.

USDA-ERS (2013). Fertilizer Use and Price. United States Department of Agriculture, Economic Research Service. Available at: http://www.ers.usda.gov/data-products/fertilizer-use-and-price.aspx.

Acknowledgements

Support for this work was provided by the Confined Animal Manure Management Program of Clemson Extension, Clemson University, Clemson, SC.

The authors are solely responsible for the content of these proceedings. The technical information does not necessarily reflect the official position of the sponsoring agencies or institutions represented by planning committee members, and inclusion and distribution herein does not constitute an endorsement of views expressed by the same. Printed materials included herein are not refereed publications. Citations should appear as follows. EXAMPLE: Authors. 2015. Title of presentation. Waste to Worth: Spreading Science and Solutions. Seattle, WA. March 31-April 3, 2015. URL of this page. Accessed on: today’s date.